We are the 317L(UNS S31703 and EN 1.4438) stainless steel tubing manufacturer. We offer various types including seamless and welded tubings with different processes like CDS, HFS, ERW, and DOM. We also provide customized services. Surface finishes include BA, AP, MP, EP, SB, No.4, and HL.

| Standard | ASTM A240, ASTM A269, ASTM A312 |

|---|---|

| Grade | 1.4438, SUS317L |

| Length | 6 meters (20 feet) to 12 meters (40 feet), Customized |

| OD | 6 mm (0.24 in) to 610 mm (24 in), Customized |

| WT | 0.5 mm (0.02 in) to 25 mm (1 in), Customized |

| Surface Finish | AP, BA, EP, MP, NO. 4, SB |

| Form | Customized, Hydraulic Tubing, Pipe, Rectangular Tubing, Round Tubing, Seamless Tubing, Square Tubing, Welded Tubing |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: | United States, India, Australia, Canada, United Kingdom, Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Anguilla, Antigua And Barbuda, Argentina, Armenia, Austria, Azerbaijan, Bahamas |

| Element | Cr | Ni | Mo | C | Mn | Si | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 18.0 – 20.0 | 11.0 – 15.0 | 3.0 – 4.0 | 0.030 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 0.10 max | Balance |

| Mechanical Property | Value(Metric) | Value(Imperial) |

|---|---|---|

| Tensile Strength | 515 MPa | 75 ksi |

| Yield Strength | 205 MPa | 30 ksi |

| Vickers Hardness (HV) | 140 – 190 | 140 – 190 |

| Brinell Hardness (HB) | 146 – 200 | 146 – 200 |

| Rockwell Hardness (HRC) | 70 – 95 | 40 |

| Elongation | 40% | 35% |

| Elastic Modulus | 193 GPa | 28,000 ksi |

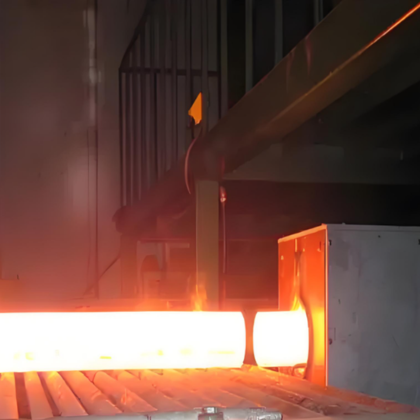

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

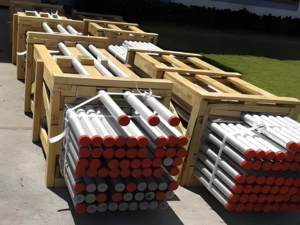

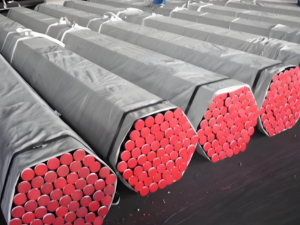

To deliver your 317L stainless steel tubes in perfect condition, our packaging solutions adhere to international shipping and safety standards. We regularly perform quality checks on our packaging process to ensure that your order meets all regulatory requirements.

When you choose us for your 317L stainless steel tubing needs, you can trust that your products will be delivered securely and ready for immediate use.