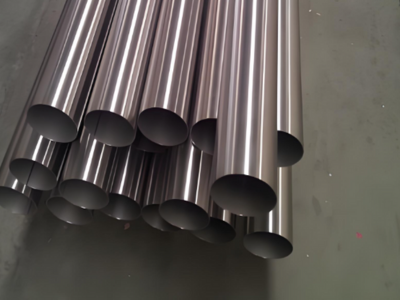

We are a supplier of 321 stainless steel pipes and tubes. We provide different types of products including:

UNS S32100, 1.4541, 321 stainless steel exhaust tubing, Aisi 321 stainless steel alloy tube, 321 stainless steel seamless pipe, welded pipe, round tube, square tube, rectangular tube, capillary tube, coiled tube, ERW pipe with high quality.

| Standard | ASTM A213, ASTM A240, ASTM A312 |

|---|---|

| Grade | 0Cr18Ni10Ti, 1.4541, 1Cr18Ni11Ti, SUS321, X6CrNiTi18-10 |

| Length | 6 m (20 ft) and 12 m (40 ft), Customized |

| OD | 6 mm (0.24 in) to 406.4 mm (16 in), Customized |

| WT | 0.7 mm (0.028 in) to 12.7 mm (0.5 in), Customized |

| Surface Finish | BA, Customized, NO. 4, Passivation, Pickling, Polishing |

| Form | Coiled Tube, Customized, Rectangular Tube, Round Tube, Seamless Pipe, Square Tube, Welded Pipe |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, United Kingdom, Australia, Canada, India, Korea, Russian Federation, South Africa, Malaysia, Turkey, Brazil, Germany, etc.

|

| Element | C | Si | Mn | P | S | Cr | Ni | Ti | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.08 max | 0.75 max | 2.00 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 9.00 – 12.00 | 5 * (C + N) min, 0.70 max | 0.10 max | Balance |

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 – 720 MPa | 74,700 – 104,400 psi |

| Yield Strength | 205 MPa | 29,700 psi |

| Brinell Hardness (HB) | 160 – 220 | 160 – 220 |

| Rockwell Hardness (HRC) | 15 – 24 | 15 – 24 |

| Vickers Hardness (HV) | 160 – 220 | 160 – 220 |

| Elongation | 40% min | 40% min |

| Elastic Modulus | 193 – 200 GPa | 28.0 – 29.0 x 10^6 psi |

High Temperature Resistance: Performs well in environments with elevated temperatures.

Excellent Corrosion Resistant: Resists oxidation and corrosion in a wide range of environments.

Durable: Maintains strength and toughness even under harsh conditions.

Formable: Can be easily formed and shaped during manufacturing.

Good Weldability: Easily welded without loss of corrosion resistance.

Versatile: Suitable for various applications across multiple industries.

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

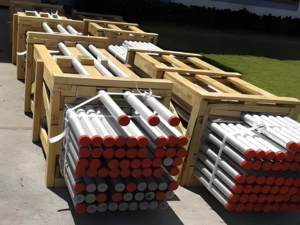

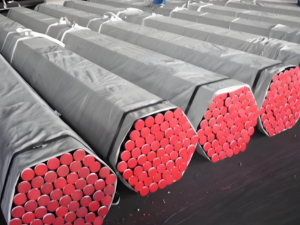

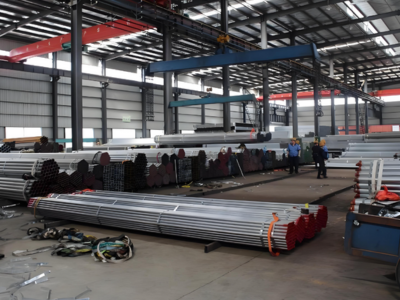

At SteelPRO Group, our packaging solutions are designed with care and precision to ensure that your products are protected throughout the shipping process.

SteelPRO Group combines unmatched quality, expertise, and reliability to deliver exceptional products and services. Choose us as your trusted partner in excellence.