SteelPRO Group is a leading manufacturer and supplier of 347 Stainless Steel Tubes in China. We provide:

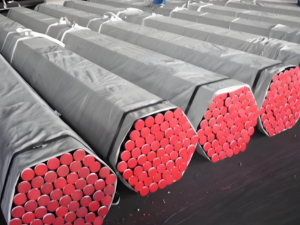

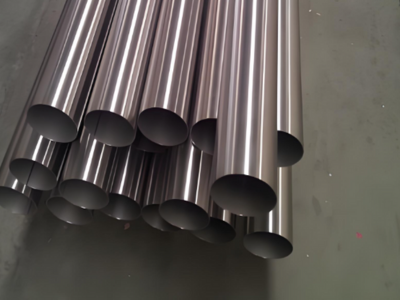

347 Stainless Steel Seamless Tube, 347 Stainless Steel Welded Tube, AISI 347 Tube, UNS S34700 Tube, EN 1.4550 Tube, ASTM A213 Seamless Tube, ASTM A312 Welded Tube, 347 Polished Tube, 347 Bright Annealed Tube, 347 No. 4 Finish Tube, etc. We offer custom fabrication, surface finishing, and precise cutting services for 347 Stainless Steel Tubes to meet specific customer requirements.

| Standard | ASTM A213, ASTM A312, EN 10216-5, JIS G3463 |

|---|---|

| Grade | 347S31, X6CrNiNb18-10 (1.4550)/19 9 Nb, Z6CNNb18-10 |

| Length | 6 meters (20 feet) or customized |

| Outer Diameter | 6mm – 250 mm (0.24 in – 9.84 in) or customized |

| Wall Thickness | 0.5 mm – 20 mm (0.02 in – 0.79 in) or customized |

| Shape | Customized, Elliptical, Oval, Rectangular, Square |

| Surface Finish | Annealed, BA, Mirror, No.4, Pickled, Polished |

| Form | 347 Stainless Steel Bar, 347 Stainless Steel Pipe, 347/347H Stainless Steel Tubing, Seamless Tube, Welded Tube, Straight Length, Coiled Tube or Customized |

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

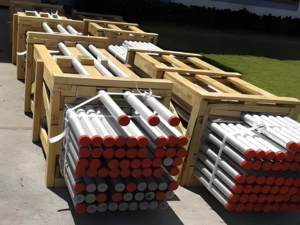

| Packaging Details: | With wooden pallets, Standard Sea Worthy Package, As Requested |

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, United Kingdom, Canada, Australia, India, Korea, Brazil, Russia, New Zealand, Turkey, Vietnam, Malaysia, Germany, Indonesia |

| lement | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Niobium (Nb) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | 0.08 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 17.00-19.00 | 9.00-13.00 | 10xC min; 1.0 max | Balance |

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 MPa | 74,700 psi |

| Yield Strength | 205 MPa | 29,700 psi |

| Elongation at Break | 40% | 40% |

| Hardness (Rockwell B) | 95 max | 95 max |

| Hardness (Brinell) | 201 max | 201 max |

| Hardness (Vickers) | 220 max | 220 max |

| Modulus of Elasticity | 193-200 GPa | 28,000-29,000 ksi |

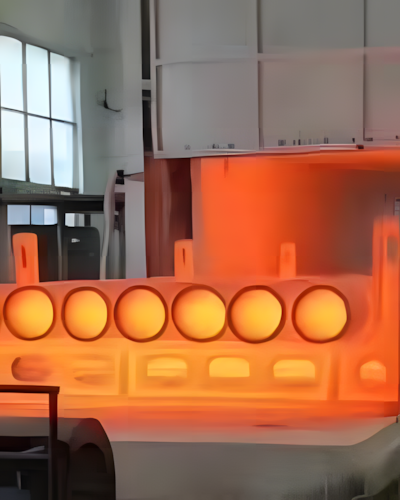

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

For 347 Stainless Steel Tubes, we provide high-quality packaging services.