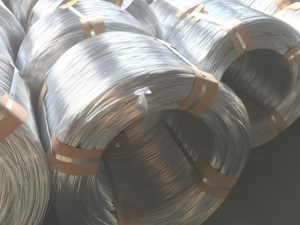

SteelPRO Group is a reliable supplier of 316 stainless steel wire from China:

We offer 316 stainless cold-drawn wire, 316 stainless annealed wire, 316 stainless bright wire, 316 stainless coated wire, 316 stainless welding wire, 316 stainless woven wire, 316 stainless spring wire, 316 stainless steel wire mesh, and 316 stainless wire rope. We provide a wide range of customizable processing options, including pickling, passivation, electropolishing, mechanical polishing, bright annealing, mirror polishing, satin finish, and matte finish.

| Standard | ASTM A313 / A313M |

|---|---|

| Grade | 0Cr17Ni12Mo2, 1.4401, SUS316 |

| Length | 9144 mm (360 in) to 15240 mm (600 in), Customized |

| Diameter | 0.5 mm (0.02 in) to 8 mm (0.315 in), Customized |

| Surface Finish | Bright Annealing, CT, Electroplating, Electropolishing, Matte, Mirror Polishing, MP, PA, Pickling, Satin, SB |

| Form | Annealed Wire, Bright Wire, Coated Wire, Cold Drawn Wire, Hard Wire, Soft Wire, Spring Wire, Welding Wire, Wire Rope, Woven Wire |

| Shape | Flat, Hexagonal, Hollow, Oval, Rectangular, Round, Solid, Square, Triangular, Wedge |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Australia, India, Canada, United Kingdom, New Zealand, Philippines, Singapore, Korea, Indonesia, Brazil, Malaysia, Vietnam, Russian Federation, Hong Kong, Taiwan, United Arab Emirates, Netherlands, Pakistan, South Africa, Germany, Mexico, Turkey, Italy, Egypt, Japan, France, Thailand, Argentina, Spain, Sweden, Saudi Arabia, Bangladesh, Cambodia, Poland, Ireland, Ukraine, Colombia, Iraq, Lithuania, Kenya, Nigeria, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.08% max | 2.00% max | 0.045% max | 0.03% max | 0.75% max | 16.00-18.00% | 10.00-14.00% | 2.00-3.00% | 0.10% max |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515-690 MPa | 74.7-100 ksi |

| Yield Strength | 205 MPa | 29.7 ksi |

| Vickers Hardness | 152-225 HV | 152-225 HV |

| Brinell Hardness | 146-217 HB | 146-217 HB |

| Rockwell Hardness | 79-95 HRB | 79-95 HRB |

| Elongation | 40% | 40% |

| Elastic Modulus | 193-200 GPa | 28-29 x10^6 psi |

Here are the characteristics of 316 stainless steel wire:

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info