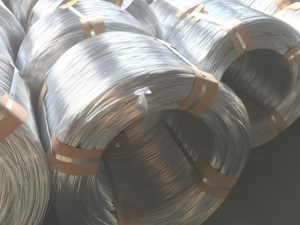

We are one of the top quality 316L stainless steel wire suppliers and manufacturers, providing a full range of products and services. Our stainless steel wire is very strong and durable, meeting various application scenarios from agriculture to aerospace.

Our products: 316L Soft Wire, Annealed Wire, 1.4404 Hard Wire, Spring Wire, SUS316L Fine Wire, Welding Wire, Wire Rope, 316 L Wire Mesh, Cable Wire, Cold-Drawn Wire, etc.

| Standard | ASTM A313/A313M, ASTM A580/A580M, EN 10088-3, ISO 683-18, JIS G4309 |

|---|---|

| Grade | 00Cr17Ni14Mo2, 0Cr18Ni12Mo2Ti, 1.4404, SUS316L, X2CrNiMo17-12-2 |

| Length | Customized |

| Diameter | 0.01 mm-10 mm (0.0004-0.4 in), Customized |

| Shape | Customized, Flat, Hexagonal, Rectangular, Ribbon Wire, Round, Square |

| Surface Finish | BA, Coating, Customized, Electropolishing, Passivation, Pickling, Shot Blasting |

| Technique | Annealing, Cold Drawing, Customized, Spooling, Straightening, Tempering |

| Form | Annealed Wire, Barbecue Wire Mesh, Coated Wire, Construction Wire Mesh, etc., Hard Wire, Spring Wire, Welding Wire, Wire Strand /rope |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, UK, Russian Federation, Canada, Hong Kong, Brazil, Egypt, France, Germany, India, Indonesia, Italy, Korea, Malaysia, Mexico, Netherlands, Philippines, Singapore, South Africa, Spain, Taiwan, Thailand, Ukraine, United Arab Emirates, Vietnam, etc.

|

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.75 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 0.10 |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 485 – 620 MPa | 70,300 – 89,900 psi |

| Yield Strength | 170 MPa | 24,656 psi |

| Vickers Hardness | 150 HV | 150 HV |

| Brinell Hardness | 146 HB | 146 HB |

| Rockwell Hardness | HRB 79 | HRB 79 |

| Elongation | 40% | 40% |

| Elastic Modulus | 193 GPa | 28,000 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We understand the importance of proper packaging to ensure the integrity of our 316L stainless steel wire during transportation and storage.

As a leading steel supplier and manufacturer, we have the expertise and quality assurance in producing 316L stainless steel wire.