SAPH440 Steel Coils – AUTOMOTIVE STEEL

SAPH440 Steel Coils – AUTOMOTIVE STEEL

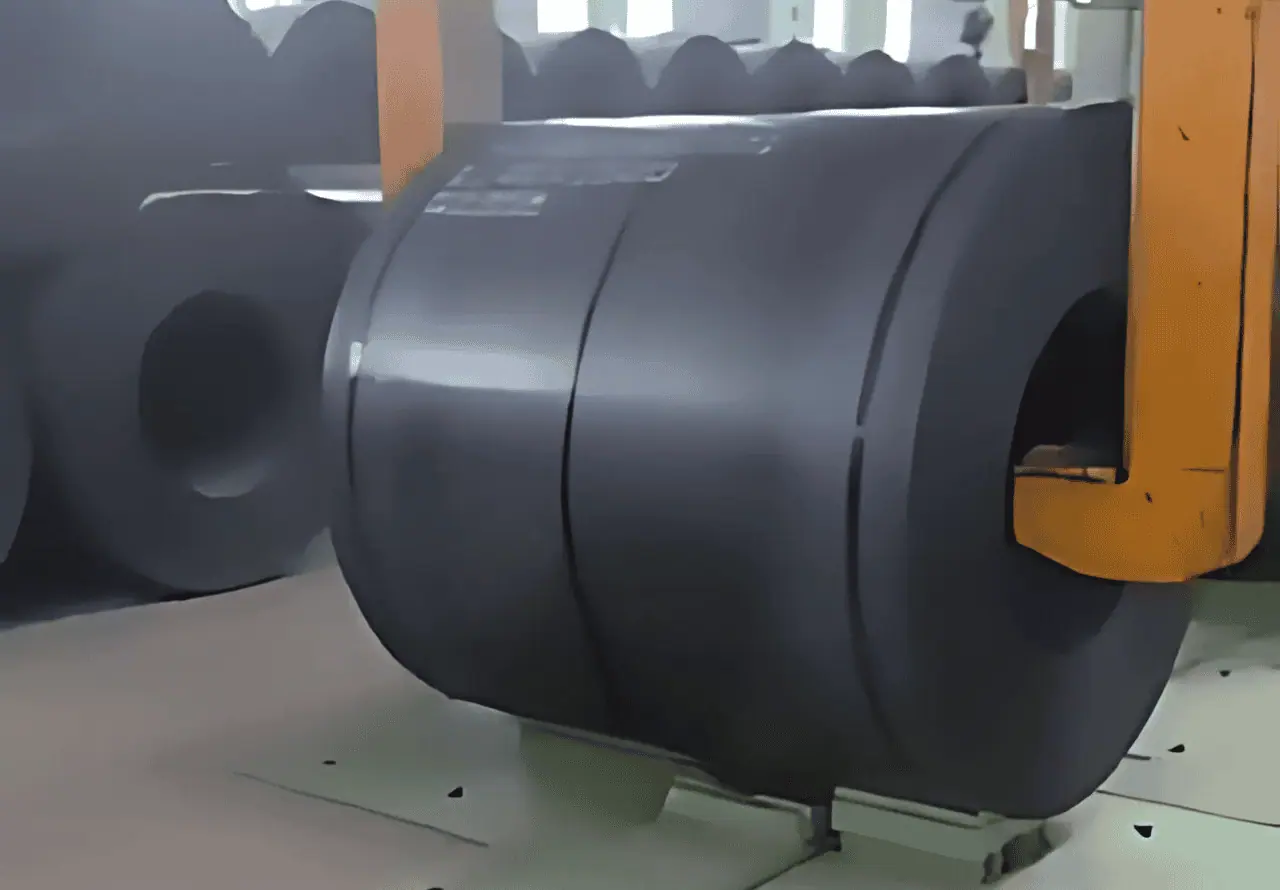

SAPH440 is a high-strength hot-rolled steel commonly used in the automotive industry for manufacturing chassis components and structural parts. The name “SAPH” stands for “Steel Automotive Press Hot,” indicating that it is specifically designed for automotive applications and is produced through hot rolling. The “440” denotes its minimum tensile strength of 440 MPa, ensuring robust performance in demanding conditions.

SteelPro Group provides SAPH440 steel hot rolled steel coils, sheets, strips, and pipes in compliance with JIS G3113 standards. Our products offer excellent strength and formability.

Description

What is SAPH440

SAPH440 is a high-strength hot-rolled steel composed of approximately 98-99% iron and 1-2% alloying elements such as carbon, manganese, and silicon. It typically comes in solid sheet or coil forms and has a greyish-metallic appearance. It is primarily used in the automotive industry to manufacture chassis components, body panels, and other structural parts. The steel is processed through hot rolling, which enhances its mechanical properties and makes it suitable for forming complex shapes.Characteristics of SAPH440 Steel

SAPH440 steel is ideal for automotive chassis applications due to its high tensile and yield strength, providing robust structural integrity. It offers superior formability, allowing the creation of complex and intricate parts, and reliable weldability, ensuring strong and durable joints in chassis construction. The steel’s enhanced impact resistance provides excellent protection in safety-critical situations, contributing to overall vehicle safety. Also, SAPH440 is often treated or coated for corrosion resistance, enabling it to withstand harsh environmental conditions and prolong the chassis’s lifespan.Available Size Range

SteelPro Group offers SAPH440 steel products in a variety of forms, including hot rolled steel coils, sheets, strips, and pipes, all designed to meet automotive industry standards.Hot Rolled Coils & Strips:

- Thickness: 1.4 mm to 5.0 mm

- Width: 800 mm to 1,850 mm

Cut-to-Length Sheets:

- Thickness: 1.4 mm to 5.0 mm

- Width: 800 mm to 1,850 mm

- Length: 2,000 mm to 10,000 mm

Pipes:

- Outer Diameter: 21.3 mm to 406.4 mm

- Wall Thickness: 2.0 mm to 12.0 mm

In addition to our standard offerings, we provide custom dimensions, specialized surface treatments, and value-added services such as bending or roll forming. Our flexible production capabilities make us a trusted partner for precision automotive components.

Chemical Compositions

| Element | Composition (max) |

|---|---|

| Carbon (C) | 0.20% |

| Manganese (Mn) | 1.50% |

| Phosphorus (P) | 0.040% |

| Sulfur (S) | 0.040% |

| Silicon (Si) | 0.30% |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm³ | 0.283 lb/in³ |

| Melting Point | 1425-1460°C | 2597-2660°F |

| Boiling Point | Not typically specified | Not typically specified |

| Thermal Conductivity | 45-55 W/m·K | 26-32 Btu·ft/h·ft²·°F |

| Electrical Conductivity | 10-15% IACS | 10-15% IACS |

| Specific Heat Capacity | 450-500 J/kg·K | 0.108-0.119 Btu/lb·°F |

| Thermal Expansion Coefficient | 11-13 × 10⁻⁶ /°C | 6.1-7.2 × 10⁻⁶ /°F |

| Electrical Resistivity | 0.2-0.4 µΩ·m | 0.12-0.24 µΩ·ft |

Mechanical Properties

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 440-510 MPa | 63,800-73,950 psi |

| Yield Strength | 275-325 MPa | 39,900-47,150 psi |

| Brinell Hardness (HB) | 130-180 HB | 130-180 HB |

| Rockwell Hardness (HRC) | 15-25 HRC | 15-25 HRC |

| Vickers Hardness (HV) | 140-210 HV | 140-210 HV |

| Elongation | 20-30% | 20-30% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Industries & Applications

| Industry | Products |

|---|---|

| Agricultural Equipment | Plow Blades, Harvester Frames, Tractor Chassis, Seeding Equipment |

| Appliances | Washing Machine Bodies, Refrigerator Panels, Microwave Casings, Dryer Drums |

| Automotive | Chassis Components, Suspension Parts, Wheel Rims, Body Panels |

| Construction | Structural Beams, Roofing, Wall Panels, Pipes |

| Energy Sector | Wind Turbine Towers, Solar Panel Frames, Oil Pipeline Components, Power Plant Structures |

| Furniture | Metal Cabinets, Shelving Units, Desks, Chairs |

| Heavy Machinery | Excavator Arms, Loader Frames, Crane Booms, Tractor Parts |

| Railway | Train Car Bodies, Rails, Braking Systems, Couplers |

| Shipbuilding | Hull Structures, Decks, Bulkheads, Frames |

Machining

SAPH440 Heat Treating Instructions: SAPH440 steel is typically used in its as-rolled condition and does not require additional heat treatment. However, if necessary, annealing can be applied to improve ductility.

SAPH440 Surface Finish: The surface of SAPH440 steel can be treated through various methods, such as hot-dip galvanizing, painting, or coating, to enhance corrosion resistance and durability.

Custom grades can be produced upon request to meet specific requirements.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...