SPCC Galvanized Steel Corrugated Roofing Sheet

SPCC Galvanized Steel Corrugated Roofing Sheet

SteelPRO Group is a premium manufacturer of SPCC galvanized steel roof panels, including corrugated sheets, flat sheets and corrugated sheets. We can also produce according to your drawings or customized requirements, suitable for a variety of scenarios such as roofs, walls and light steel structures. We provide a variety of surface treatments, such as passivation and oiling, to ensure corrosion resistance and environmental protection. We also provide Gi sheets, coils, pipes, PPGI, etc. that meet international standards, with various grades such as DX51D, Q195, DC01, etc.

- Standard: JIS G 3302, ASTM A653/A653M, EN 10346, GB/T 2518, etc.

- Grades: DX51D+Z, DC01+Z, CS Type A/B, SECC, SGCC

- Technique: Hot dip galvanizing and electro galvanizing

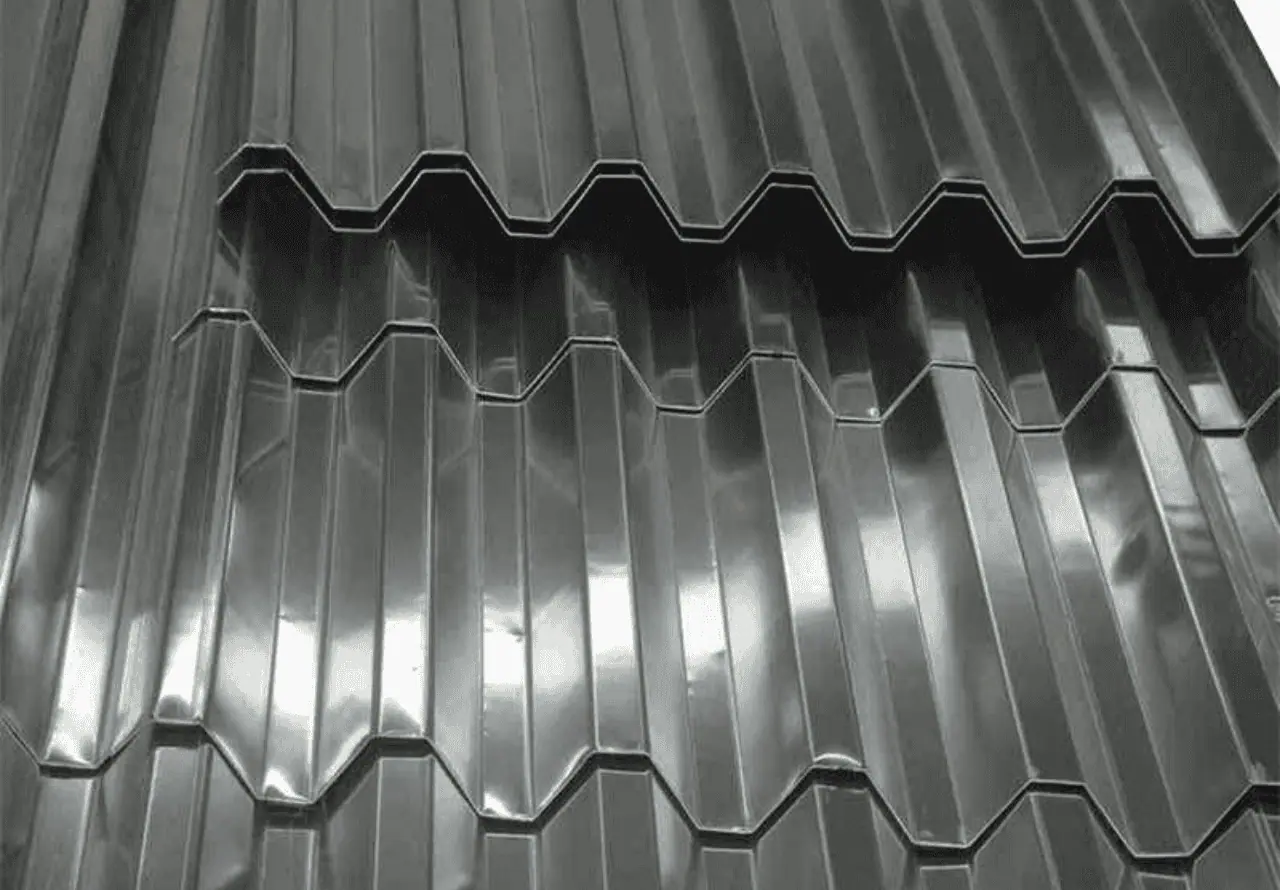

- Type: Corrugated Roofing Sheet, Trapezoidal Roofing Sheet, or Custom

- Hardness: Soft, Semi-hard, Full hard

- Certification: ISO 9001, CE

SPCC Galvanized Steel Corrugated Roofing Sheet

SPCC Galvanized Steel Corrugated Roofing Sheet

Product Specifications

Product Specifications

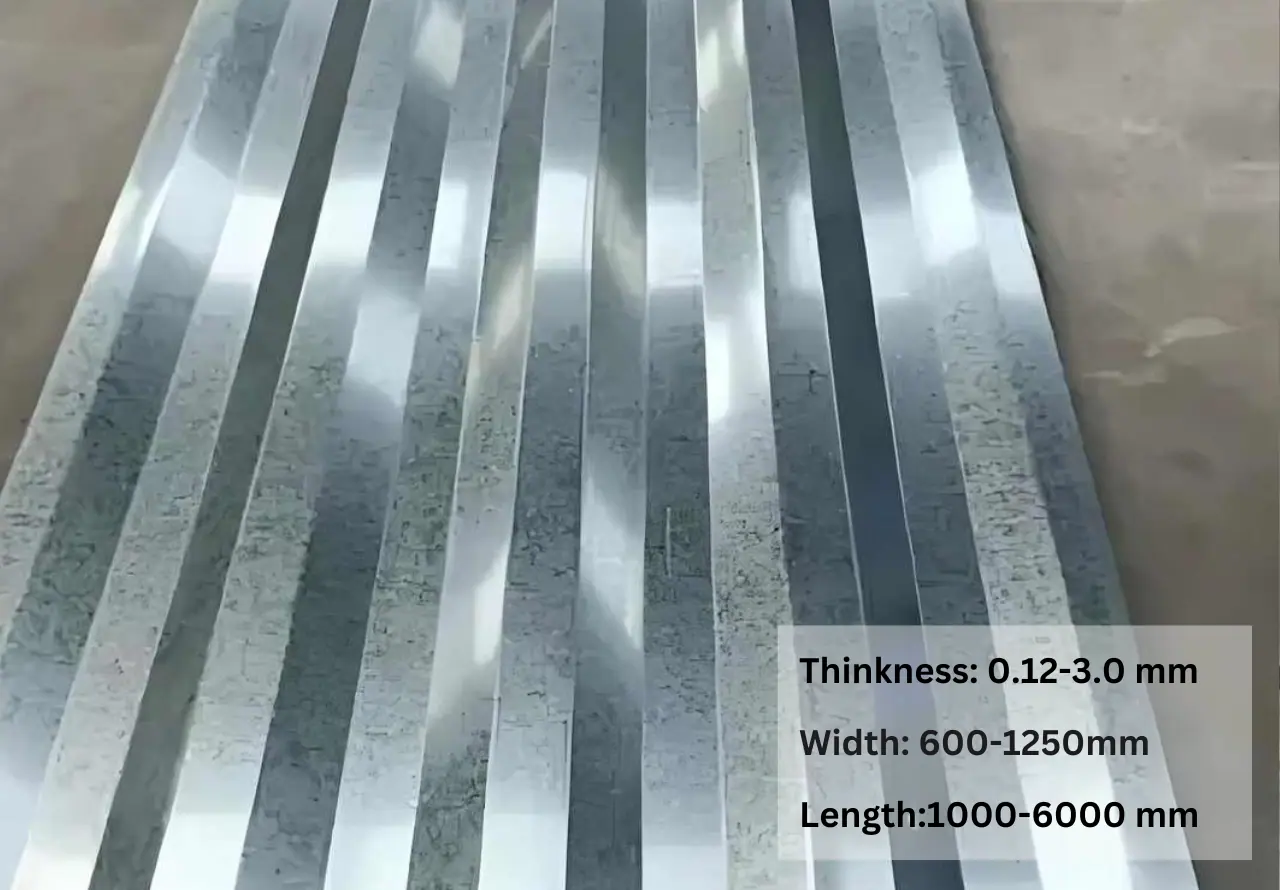

| Product Name | SPCC Galvanized Steel Corrugated Roofing Sheet |

| Thickness | 0.12 mm – 3.0 mm |

| Width | Before corrugation: 600 mm – 1250 mm |

| After corrugation: 500 mm – 1100 mm | |

| Length | 1000 mm – 6000 mm, or customized |

| Zinc Layer | 30-275 g/m² |

| Coating Material | Zinc or Aluzinc (Aluminum-Zinc Alloy) |

| Wave Width | 76 mm – 250 mm, Customized |

| Wave Height | 18 mm – 50 mm, Customized |

| Number of Peak/Valley | Customized |

| Top Coating Thickness | 15 – 25 μm |

| Back Coated Thickness | 15 – 25 μm |

| Color | According to RAL color chart or customized |

| Edge | Mill edge, Slit edge |

| Surface Treatment | Anti-finger print, Skin pass, Oiled, Dry, Chromated, Embossed, Lamination |

| Spangle | Big, Regular, Mini, Zero |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, UV Aging Test, Temperature-Humidity Cycle, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching, Surface Coating |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao, or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

| Composition (%) | ≤ 0.15 | ≤ 0.60 | ≤ 0.05 | ≤ 0.05 | ≤ 0.03 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 410 |

| Yield Strength (MPa) | ≥ 205 |

| Elongation (%) | ≥ 28 |

| Vickers Hardness (HV) | 85 – 120 |

| Brinell Hardness (HB) | 70 – 100 |

| Rockwell Hardness (HRB) | ≤ 60 |

| Elastic Modulus (GPa) | ~ 210 |

Industries & Applications

Industries & Applications

- Buildings and structures: workshops, warehouses, corrugated roofs and walls, rainwater and drainage pipes, rolling shutters, roofing materials, sidewall materials, partitions, soundproof walls, pipes, shutters, garage doors, fences, corrugated steel pipes, lightweight steel structures.

- Electrical appliances: refrigerators, washing machines, switch cabinets, instrument cabinets, air conditioning units, microwave ovens, bread machines, vending machines, gas boilers, gas ovens, toasters, air conditioners/heaters, lampshades.

- Furniture: central heating panels, lampshades, bookcases.

- Automotive parts: exterior decoration of cars and trains, cladding panels, containers, partition panels, mufflers, exhaust silencers, exhaust pipes (tail pipes), oil filter pipes, passenger car floors, truck bottoms, air filter covers, hose clamps, brake pad covers.

- Agriculture: greenhouse pipes, silos, tobacco leaf dryers, grain dryers, agricultural machinery, greenhouse panels.

- Industrial machinery: industrial equipment, insulation materials, water heaters, heat exchangers, dryers, waste incinerators, containers.

- Others: Writing boards, trash cans, billboards, timers, typewriters, dashboards, weight sensors, photographic equipment.

Other Infomation

Other Infomation

When using and maintaining SPCC galvanized steel roof panels, there are several aspects that require special attention to ensure that they remain in good condition in different environments.

In terms of use, this galvanized steel is very suitable for general outdoor environments, but if it is in a highly corrosive environment near the sea or industrial area, it should be avoided for long-term exposure, because excessive acid, alkali or salt will damage the galvanized layer. When installing, it is best to reduce on-site cutting, especially the part where the edge is directly exposed to rainwater, which can be used for additional protection.

In terms of maintenance, simple daily cleaning can extend the life. It is recommended to clean the surface with clean water regularly, especially in areas with heavy pollution or high salt content, so as to avoid rust spots on the surface. In addition, check for damage to the coating. Minor scratches can be repaired with zinc spray.

When storing, choose a dry and ventilated environment, and try not to let it directly contact the ground to prevent moisture and rust. If you have any questions, we are always available for support!

Our Inventory

Our Inventory

As a galvanized steel manufacturer and supplier, SteelPRO Group has become the preferred partner for many customers in steel products. We have established long-term cooperative relationships with well-known suppliers in the industry to ensure the consistency and stability of quality from raw materials to finished products. The group has advanced production lines and automated equipment with an annual output of millions of tons, which can quickly meet the needs of various projects, whether large-scale projects or small batch customization. We strictly implement international quality standards and pay attention to environmental protection and sustainable development. We are committed to providing cost-effective steel products by optimizing production processes and reducing energy consumption.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

SteelPRO Group uses professional and sturdy packaging to ensure that each batch of products is intact during transportation. Our steel products are usually protected by waterproof and anti-corrosion measures, with additional sturdy strapping and wooden pallets to prevent damage during long-distance transportation. For special needs, we also provide customized packaging solutions to ensure that each product reaches you safely and with consistent quality.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Can SPCC galvanized steel be repainted?

Yes, the cold rolling process gives the steel a high-quality flat surface, which is very suitable for subsequent painting. You can paint or other surface treatments as needed.

How durable is SPCC galvanized steel?

Our galvanized steel has excellent durability and can withstand the harsh conditions of outdoor sun and rain, and the galvanized layer can effectively prevent rust in long-term use, ensuring a longer life of the material.

How does SteelPRO Group ensure product quality?

SteelPRO Group strictly follows international standards and adopts advanced production processes and quality control processes to ensure that each batch of products meets high quality requirements. We also provide complete quality inspection reports for customers’ reference.

Does SteelPRO Group support customized products?

Yes, we can provide SPCC galvanized steel sheets of different specifications, thicknesses, surface treatments and shapes according to the specific needs of customers, helping customers find the most suitable solutions.

How is SteelPRO Group's after-sales service?

We provide comprehensive after-sales service, including product technical support and after-sales consultation. Whether it is technical problems during use or subsequent maintenance needs, our team will provide professional support.

What measures does SteelPRO Group take in terms of environmental protection?

SteelPRO Group is committed to sustainable production and uses environmentally friendly surface treatment technologies such as chromium-free passivation to reduce the emission of harmful substances during the production process and meet environmental standards.

CONTACT

Certificates and Cooperation

Certificates and Cooperation