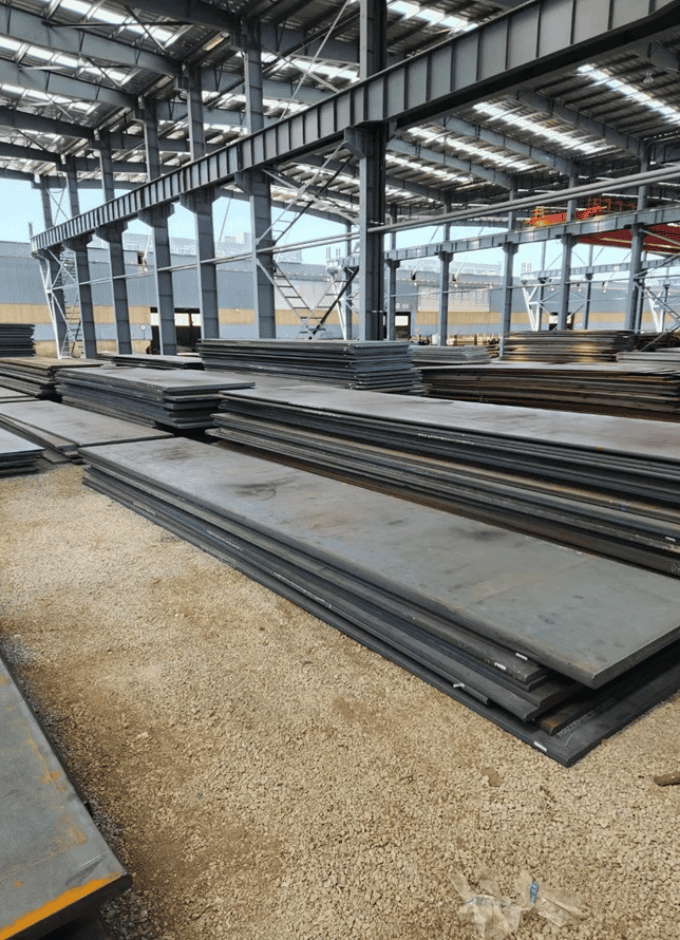

HIGH CARBON STEEL

Exceptional Hardness. Superior Strength. Enhance Your Projects with High Carbon Steel.

Introduction to High Carbon Steel

Benefits of High Carbon Steel

- High carbon steel offers several distinct advantages:

- High Strength: It provides superior strength, making it suitable for heavy-duty applications.

- Wear Resistance: The increased carbon content enhances the steel’s wear resistance, extending the life of components.

- Hardness: High-carbon steel is particularly hard, which is beneficial for cutting and shaping applications.

- Heat Treatment: The steel responds well to heat treatment, allowing for adjustments in hardness and toughness.

- Cost-Effectiveness: Compared to alloy steels, high carbon steel offers high performance at a lower cost.

- Versatility: It can be used in a wide range of applications, from cutting tools to springs and wires.

Types of High Carbon Steel

- High carbon steel comes in several grades, each designed for specific uses:

- AISI 1095: Contains about 0.95% carbon, known for its high hardness and wear resistance. Used in knives and cutting tools.

- AISI 1080: Contains around 0.80% carbon, offers a balance of strength and toughness. Commonly used in springs and industrial blades.

- AISI 1065: With approximately 0.65% carbon, it provides good wear resistance and is used for making hand tools and large machine parts.

- AISI 1055: Contains about 0.55% carbon, known for its toughness and impact resistance. Suitable for tools like axes and hammers.

- AISI 1075: Features approximately 0.75% carbon, offering high strength and moderate ductility. Used in saw blades and metal cutting tools.

- AISI 1085: Contains about 0.85% carbon, providing high hardness and strength, making it ideal for high-performance springs and blades.

- AISI 1090: With a carbon content of approximately 0.90%, this grade offers excellent wear resistance and is used in applications requiring high hardness, such as cutting tools and wear-resistant machine parts.

Industries & Applications

High carbon steel can be used in a variety of industries and applications, as it is a very versatile and commonly used form of steel.

Some common industries and applications include:

Automotive Industry

Construction Industry

Manufacturing

Tool Making

Railways

Agriculture

Dimensions & Properties

| AISI 1060 | AISI 1080 | AISI 1095 | |

|---|---|---|---|

| Yield Strength | 480 MPa (70 ksi) | 540 MPa (78 ksi) | 580 MPa (84 ksi) |

| Tensile Strength | 780 MPa (113 ksi) | 850 MPa (123 ksi) | 900 MPa (131 ksi) |

| Material Standard | ASTM A29 / A29M | ASTM A29 / A29M | ASTM A29 / A29M |

| Vickers Hardness | 220-280 HV | 240-300 HV | 260-320 HV |

High Carbon Steel When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

Is High Carbon Steel Stronger than Regular Steel?

Yes, high carbon steel is stronger and harder than regular (low carbon) steel due to its higher carbon content.

What Type is High Carbon Steel?

High carbon steel typically contains 0.6% to 1.0% carbon and is known for its high strength and hardness.

Can High Carbon Steel be Welded, and if so, What Special Procedures are Required?

Yes, high carbon steel can be welded, but it requires preheating, controlled heat input, and post-weld heat treatment to avoid cracking and brittleness.

How Resistant is High Carbon Steel to Corrosion, and What Treatments Can Enhance its Resistance?

High carbon steel is not very resistant to corrosion. Applying coatings, galvanizing, or using corrosion inhibitors can enhance its resistance.

How Does the Machinability of High Carbon Steel Compare to that of Medium and Low Carbon Steels?

High carbon steel is more difficult to machine than medium and low carbon steels due to its higher hardness and brittleness. Proper tooling and machining techniques are required.