HOT ROLLED STEEL

Unmatched Strength. Cost-Effective. Enhance Construction with High-Quality Hot Rolled Steel.

Introduction to Hot Rolled Steel

Benefits of Hot Rolled Steel

- Hot rolled steel offers numerous benefits that make it an attractive choice for various industrial applications:

- Cost-Effective and Versatile: The hot rolling process cuts costs, making hot rolled steel budget-friendly and flexible for structural beams to automotive components.

- High Strength and Availability: Hot rolled steel offers sufficient strength for construction and heavy machinery, available in various forms and sizes.

- Workability and Durability: High-temperature processing makes hot rolled steel easier to cut, weld, and machine, enhancing toughness and durability.

- Surface Texture: The rough surface of hot rolled steel, compared to cold rolled steel, provides better adhesion for coatings and paint, ideal for finishing applications.

- Energy Efficiency: The hot rolling process consumes less energy than cold rolling, boosting production efficiency and sustainability.

- Resistance to Deformation: Hot rolled steel resists deformation under high loads, ideal for heavy-duty applications requiring structural integrity.

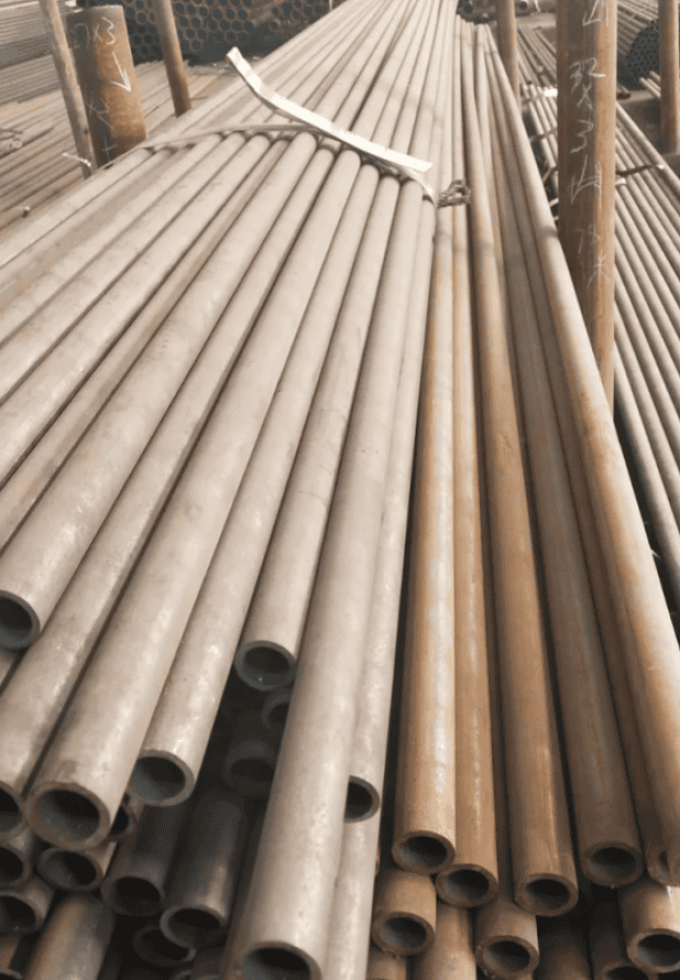

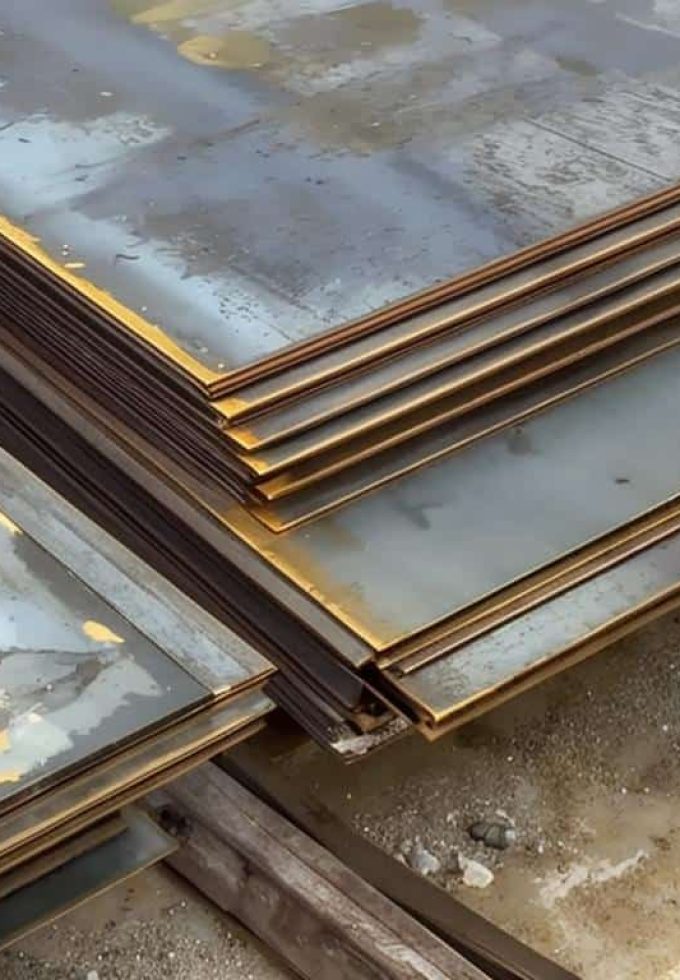

Types of Hot Rolled Steel

- Hot rolled steel comes in various types, each designed for specific needs and applications. Knowing these types helps in choosing the right material for your project.

- Hot Rolled Steel Sheet:Used in automotive and appliance manufacturing, offering flexibility and durability.

- High Strength Hot Rolled Steel Sheet:Ideal for applications requiring higher strength, such as construction and heavy machinery.

- Hot Rolled Steel with Specific Properties:Customized for particular performance requirements, such as improved wear resistance or corrosion resistance.

- Hot Rolled Steel Bars:Commonly used in construction for reinforcing concrete structures and producing machinery parts.

- Hot Rolled Steel Plates:Utilized in shipbuilding, heavy machinery, and construction for creating sturdy, large structures.

- Hot Rolled Steel Structural Shapes:Includes I-beams, H-beams, and other shapes used in construction and infrastructure projects.

- Hot Rolled Steel Sheet Pile:Used for retaining walls, bridge abutments, and other applications requiring soil retention and support.

Industries & Applications

Hot rolled steel plays a vital role in numerous industries, contributing significantly to the development of infrastructure and technology.

Some common industries and applications include:

Construction

Automotive

Heavy Machinery

Energy

Shipbuilding

Railroad

Dimensions & Properties

| ASTM A36 | Grade 50 | SAE 1045 | |

|---|---|---|---|

| Yield Strength | 250 MPa (36 ksi) | 345 MPa (50 ksi) | 310 MPa (45 ksi) |

| Tensile Strength | 400-550 MPa (58-80 ksi) | 450 MPa (65 ksi) | 565 MPa (82 ksi) |

| Material Standard | ASTM A36 / A36M | ASTM A572 / A572M | SAE J403 |

| Vickers Hardness | 100-140 HV | 150-190 HV | 170-210 HV |

Hot Rolled Steel When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

What is the difference between hot rolled steel and cold formed steel?

Hot rolled steel is formed at high temperatures, making it easier to shape and less precise, while cold formed steel is shaped at room temperature, resulting in a smoother finish and tighter tolerances.

Is hot rolled steel easy to weld?

Yes, hot rolled steel is generally easy to weld due to its lower carbon content and consistent material properties.

How do you harden hot rolled steel?

Hot rolled steel can be hardened through heat treatment processes such as quenching and tempering.

How do you care for hot rolled steel?

To care for hot rolled steel, keep it dry, apply protective coatings to prevent rust, and store it in a controlled environment to avoid exposure to moisture and chemicals.

What is the best grade of hot rolled steel called?

The best grade of hot rolled steel depends on the application, but ASTM A36 is commonly known for its good balance of strength, ductility, and weldability.