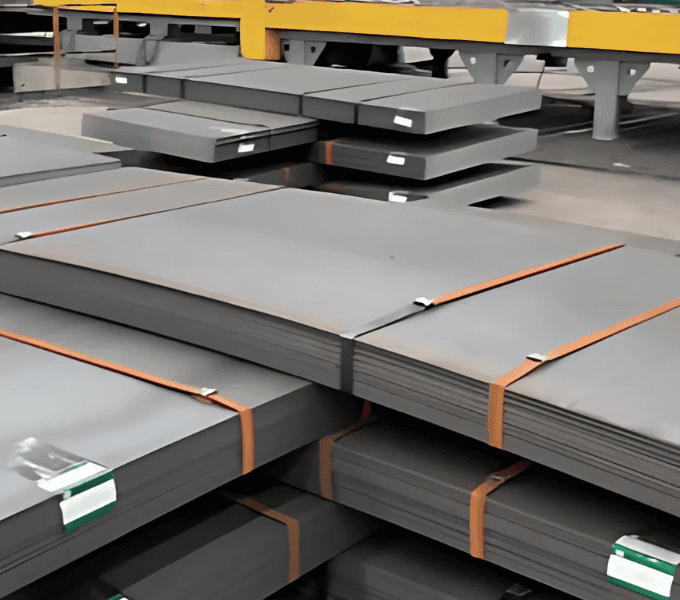

Introduction to Nuclear Grade Steel

Nuclear grade steel is a special type of steel used in the nuclear industry, particularly in nuclear power plants. It is designed to withstand extreme conditions, such as high radiation, intense heat, and pressure.

This steel, often an austenitic alloy, has exceptional strength, durability, and resistance to corrosion. Stainless steel grades are commonly used due to their ability to endure a nuclear reactor’s harsh, corrosive environment. The stringent standards, such as ASME codes, for nuclear grade steel ensure it can maintain structural integrity over long periods. It must pass rigorous testing to confirm its reliability and safety. This material is crucial for constructing reactors, pressure vessels, and other critical components in nuclear facilities, ensuring safe and efficient operation.

Benefits of Nuclear Grade Steel

- Reduced weight of structures while maintaining strength

- Enhanced safety in nuclear environments

- Increased payload capacity

- Improved performance in extreme conditions

- Resistance to radiation damage

- Easy weldability and cutting

Types of Nuclear Grade Steel

Selecting the right steel is crucial for safety and performance in nuclear reactors. Here are the most commonly used types:

- Austenitic Stainless Steels (304 and 316)

- Known for excellent corrosion resistance and high-temperature strength.

- Widely used in nuclear reactors.

- Low Alloy Steels (SA-508 and SA-533)

- Offer a good balance of strength, toughness, and radiation resistance.

- Commonly used in reactor pressure vessels.

- Nickel Alloys (Inconel 600 and 690)

- Highly resistant to corrosion and can withstand very high temperatures. Essential in core reactor parts.

Industries & Applications

Some common industries and applications include:

Nuclear Power Plants

Aerospace

Defense

Medical Equipment

Research Facilities

Oil & Gas

Dimensions & Properties

| Property | SA508 | SA533 | 304L | 316L |

|---|---|---|---|---|

| Yield Strength | 250-380 MPa (36.3-55.1 ksi) | 345 MPa (50.0 ksi) | 205 MPa (29.7 ksi) | 205 MPa (29.7 ksi) |

| Tensile Strength | 485-620 MPa (70.3-89.9 ksi) | 485-655 MPa (70.3-95.0 ksi) | 515-740 MPa (74.7-107.3 ksi) | 515-690 MPa (74.7-100.1 ksi) |

| Material Standard | ASTM A508 | ASTM A533 | ASTM A240/A240M | ASTM A240/A240M |

| Vickers Hardness | 170-220 HV | 190-230 HV | 140-190 HV | 150-220 HV |

Nuclear Grade Steel When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

What steel is used in the nuclear industry?

Austenitic stainless steels and low-alloy steels are commonly used in the nuclear industry.

Which type of steel is preferred predominantly in the nuclear industry?

Austenitic stainless steels, such as 304 and 316, are predominantly preferred due to their corrosion resistance and strength.

What type of steel is used in nuclear reactors?

Austenitic stainless steels and low-alloy steels are typically used in nuclear reactors for their durability and resistance to radiation damage.

What steel is used for radiation shielding?

High-density materials like lead are commonly used for radiation shielding, but for steel, low-alloy steels and heavy concrete are used.

What is the steel used in nuclear reactor pressure vessels?

Low-alloy steels, such as SA-508, are used in nuclear reactor pressure vessels for their high strength and toughness.