Beveling

SteelPRO Group provides precise beveling services for all metals, including pipe beveling, ensuring high-quality edges for welding and assembly in various industries.

What is Beveling?

Beveling is a commonly used process in manufacturing, typically at a 45-degree angle. It creates an angled edge on a workpiece, usually metal, to facilitate joining or welding operations. The purpose of beveling is to provide a smooth transition between two surfaces, ensuring better fit and weld quality.

It also increases the contact area of the weld, improving the overall welding effectiveness. This process can be applied to all types of metals, including steel and aluminum.

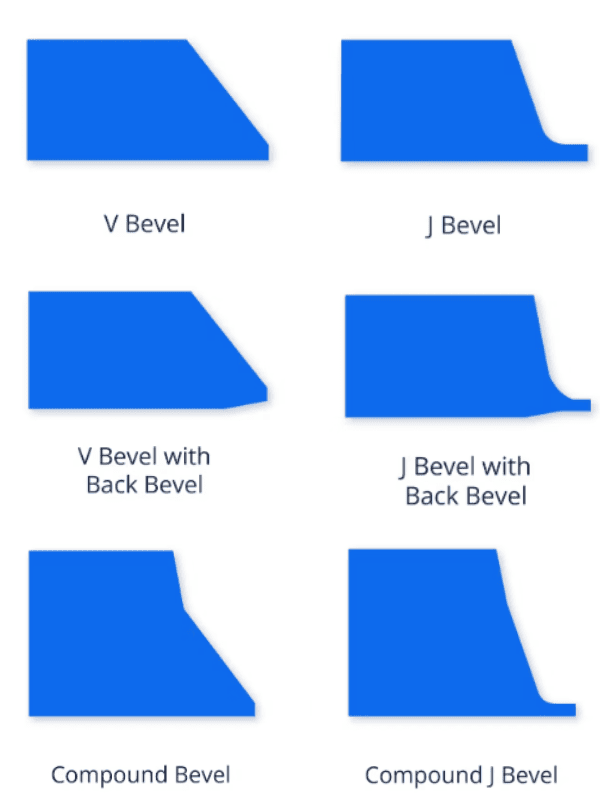

Types of Bevel

- V-Bevel: This is the most common type, featuring a “V” shape. It typically involves a 60-degree angle and is used to create a groove for deeper penetration in welding.

- U-Bevel: This type has a rounded shape, resembling a “U.” It allows for increased weld pool volume and is often used in thicker materials.

- J-Bevel: This bevel has a hook-like shape, allowing for good penetration while providing a smooth transition. It is often used in pipe welding.

- Square Bevel: This type has a straight edge with a 90-degree angle. It is generally used for thinner materials or where full penetration is not necessary.

- Single Bevel: In this method, only one side of the joint is beveled, creating a single slope. It is commonly used in butt joints.

- Double Bevel: Both sides of the joint are beveled, allowing for a wider groove and deeper penetration. This is useful for thicker materials.

- Flared Bevel: This type features a flared edge, which helps improve weld accessibility and is often used in piping applications.

Methods of Achieving Beveling

- Bevel (Groove):

Beveling is a process of creating an angled edge, typically at 45 degrees, for welding preparation. The bevel angle must be precise to ensure strong welds. - Flame and Plasma Cutting:

These methods use high heat to cut and bevel metal edges. Plasma cutting is faster and more precise than flame cutting, but both can cause heat distortion. - CNC Cutting Machines: Automate beveling with high precision for complex parts, requiring accurate programming for desired angles.

- Mechanical Cutting: Uses milling or grinding to create bevels, offering precise control but slower than other methods.

- Laser Cutting: Provides precise, smooth bevels with a focused light beam, ideal for thin metals but less effective on thick materials.

- Waterjet Cutting: Uses high-pressure water and abrasives to bevel metal without heat distortion, suitable for various materials but slower.

Why Choose Us

- Versatile Beveling Solutions: We provide beveling for all metals, from shallow to deep cuts, and handle long metal pieces with ease.

- Precision and Quality: Our advanced cutting technology ensures precise, clean bevels every time, helping you achieve the best possible welds or assembly.

- Experienced Team: With years of industry experience, our skilled professionals guarantee high-quality results and tailored solutions for each project.

- Industry Adaptability: We serve diverse industries, delivering customized beveling solutions for any project size or complexity.

- Full Range Metal Beveling: We offer beveling services for a wide range of metals, including pipe beveling and more, meeting the needs of every application.

Industries Served by Beveling

Some common industries and applications include:

Construction

Shipbuilding

Oil & Gas

Automotive

Aerospace

Heavy Machinery

Energy & Power

Power Generation

FAQ

What are 3 reasons for beveling?

Improved weld strength, better fit, and smoother edges.

What is the correct angle for a bevel?

Typically 45 degrees, but it depends on the welding requirements.

What is the advantage of beveling?

It provides stronger welds and a better fit between metal parts.

What beveling method is best for my specific metal type?

Plasma cutting for steel, waterjet for aluminum, laser cutting for precision needs.

What materials can be beveled?

Beveling can be done on a wide range of metals, including carbon steel, stainless steel, and aluminum, using methods like plasma cutting, laser cutting, or mechanical cuttin

Why is beveling important for welding?

Beveling increases the surface area for welding, ensuring stronger, more durable weld joints, especially for thicker materials.

Can you handle large-volume beveling projects with tight deadlines?

Yes, we have the equipment and capacity to manage large-scale projects efficiently.

How do you ensure the bevels meet precise angle requirements for welding?

We use advanced CNC machines and quality checks to ensure accurate angles.