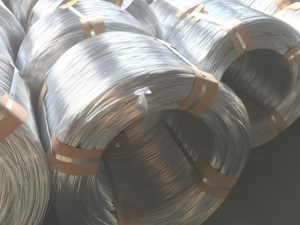

We are an AISI 302 stainless steel wire supplier. We offer various types of 302 stainless steel wire including:

UNS S30200, 302 spring steel wire, cold-drawn stainless steel wire, bright stainless steel wire, annealed stainless steel wire, hard-drawn stainless steel wire, and heat-treated stainless steel wire for weaving, fasteners, and precision applications.

| Standard | AISI 302, EN 1.4310 |

|---|---|

| Grade | 12Cr18Ni9, SUS 302, UNS S30200, X10CrNi18-8 |

| Length | 1 meter (3.28 ft) to 300 meters (984 ft), Customized |

| Diameter | 0.14 mm (0.006 in) to 16 mm (0.625 in), Customized |

| Surface Finish | BA, Coating, Customized, EP, Passivation, Pickling |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Korea, United Kingdom, India, Russian Federation, Brazil, etc.

|

| Element | C | Mn | Si | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.15 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 8.00 – 10.00 | Balance |

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 860 – 1030 MPa | 125 – 150 ksi |

| Yield Strength | 515 MPa | 75 ksi |

| Brinell Hardness (HB) | 160 – 190 HB | 160 – 190 HB |

| Rockwell Hardness (HRC) | 20 – 39 HRC | 20 – 39 HRC |

| Vickers Hardness (HV) | 200 – 230 HV | 200 – 230 HV |

| Elongation | 40% | 40% |

| Elastic Modulus | 193 GPa | 28,000 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

Our reliable and well-designed packaging ensures that your 302 stainless steel wire is delivered safely and efficiently, helping us earn your trust.

When it comes to choosing the right supplier for your 321 stainless steel sheet, plate, or foil needs, SteelPRO Group stands out with its commitment to quality and service. Here’s why: