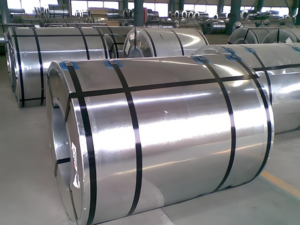

SteelPRO Group is a SS 904L Coil manufacturer and supplier. We offer a wide range of shapes, sizes and thicknesses with excellent corrosion resistance. We also produce 904L Coil in specific sizes and finishes based on custom requirements.

We have a wide range of stock: ASTM A240 904L Stainless Steel Coil, N08904 Stainless Steel Coil, 904L Cold Rolled Coil, Hot Rolled Coil, Wide Coil, Perforated Coil, Brushed Coil, etc.

| Standard | ASTM A240, EN 10088-2, GB/T 24511, JIS G4305 |

|---|---|

| Grade | 1.4539, 904S13, N08904, X1NiCrMoCu25-20-5 |

| Length | Customized |

| Thickness | 0.3 mm-50 mm (0.012-2 in), Customized |

| Full Width | 1000 mm-2000 mm (39.37-78.74 in), Customized |

| Surface Finish | 2B, 8K, BA, Brushed, Customized, No.1, No.4, Polished |

| Technique | Cold Drawn, Cold Rolled, Hot Rolled |

| Form | 904L Cold-Rolled Coil, 904L Hot-Rolled Coil, Brushed Coil, Coated Coil, Customized, Embossed Coil, Mirror Finish Coil, Plate, Precision Coil, Sheet, Strip, Wide Coil |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, France, Germany, United Kingdom, Japan, Russian Federation, Italy, South Korea, Netherlands, Taiwan, Brazil, India, Belgium, Australia, Indonesia, Vietnam, Philippines, Hong Kong, Finland, Turkey, Switzerland, Sweden, Poland, Spain, Canada, etc.

|

| Element | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Copper (Cu) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0-2.0 | ≤ 0.020 | ≤ 2.00 | ≤ 1.00 | ≤ 0.045 | ≤ 0.035 |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 490-685 MPa | 71-99 ksi |

| Yield Strength | ≥ 220 MPa | ≥ 32 ksi |

| Vickers Hardness | 145 HV (typical) | 145 HV (typical) |

| Brinell Hardness | 150 HB (typical) | 150 HB (typical) |

| Rockwell Hardness | 70 HRB (typical) | 70 HRB (typical) |

| Elongation | ≥ 35% | ≥ 35% |

| Elastic Modulus | 190-210 GPa | 27.6-30.4 x 10³ ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

To ensure that the 904L stainless steel coils are intact during transportation, the following packaging methods are used.

SteelPRO Group is committed to being your reliable partner for high-quality stainless steel materials, distinguished by our dedication to excellence and customer satisfaction.