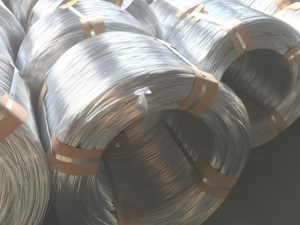

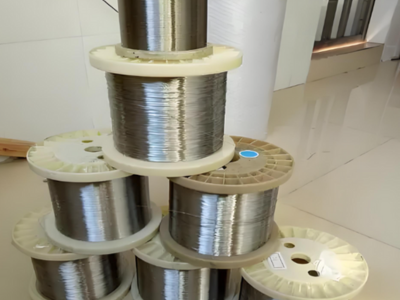

SteelPRO Group is a reliable supplier of 316 stainless steel cables from China:

We offer various 316 stainless steel cable products including 316 Hot Rolled Cable, 316 Cold Drawn Cable, 316 Seamless Cable, and 316 Welded Cable. We provide a wide range of customizable processing techniques such as cold drawing, heat treatment, annealing, quenching, tempering, stranding, swinging, and passivation.

| Standard | ASTM A492 |

|---|---|

| Grade | 0Cr17Ni12Mo2, 1.4401, SUS316 |

| Diameter | 1.5 mm (0.06 in) to 12 mm (0.47 in), Customized |

| Construction | 12×7, 1×19, 1×7, 6×19, 7×19, 7×7, 8×19 |

| Surface Finish | BA, CT, Electropolishing, GZ, Mirror Polishing, MP, PA, Pickling, Satin, SB |

| Technique | Annealing, Coiling, Cold Drawing, Heat Treatment, Passivation, Stranding, Swaging |

| Form | Braided Cable and wire, Galvanized Cable, Nylon Coated Cable, PVC Coated Cable, Twisted Cable |

| Shape | Flat, Hexagonal, Oval, Rectangular, Round Cable, Square, Trapezoidal, Wedge |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Anguilla, Antigua And Barbuda, Argentina, Armenia, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Bosnia And Herzegovina, Botswana, Brazil, Brunei Darussalam, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Central African Republic, Chad, Chile, Colombia, Congo, Congo, Democratic Republic, Cook Islands, Costa Rica, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Range | 0.08% max | 2.00% max | 0.045% max | 0.030% max | 1.00% max | 16.00-18.00% | 10.00-14.00% | 2.00-3.00% | 0.10% max | Balance |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 520 – 700 MPa | 75,000 – 101,000 psi |

| Yield Strength | 290 – 370 MPa | 42,000 – 54,000 psi |

| Vickers Hardness | 150 – 200 HV | 150 – 200 HV |

| Brinell Hardness | 160 – 220 HB | 160 – 220 HB |

| Rockwell Hardness | 80 – 90 HRB | 80 – 90 HRB |

| Elongation | 40 – 60 % | 40 – 60 % |

| Elastic Modulus | 193 – 200 GPa | 28,000 – 29,000 ksi |

Here are the characteristics of 316 stainless steel cable:

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info