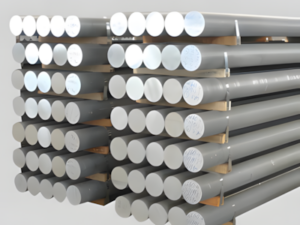

310S Stainless Steel Round Bar | Rod

310S Stainless Steel Round Bar | Rod

SteelPRO Group is a leading manufacturer and supplier of 310S Stainless Steel Round Bars and Rods in China. We provide:

Hot-Rolled 310S Stainless Steel Round Bars, Cold Drawn 310S Stainless Steel Round Bars, Centerless Ground 310S Stainless Steel Rods, Bright Annealed 310S Stainless Steel Round Bars, Peeled 310S Stainless Steel Rods, Forged 310S Stainless Steel Round Bars, Polished 310S Stainless Steel Round Bars and Annealed 310S Stainless Steel Rods. We provide processing services such as cutting, machining, grinding, and heat treatment to meet your needs.

| Standard | ASME SA479, ASTM A276, ASTM A479, BS 970, DIN 17440, EN 10088-3, JIS G4303 |

|---|---|

| Grade | 1Cr25Ni20Si2, S31008, SUS310S, X8CrNi25-21 (1.4845) |

| Length | 2000mm – 6000mm (79in – 236in), Customized |

| Diameter | 6mm – 500mm (0.24in – 19.7in), Customized |

| Shape | Customized, Hexagonal, Round, Square |

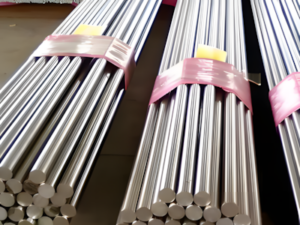

| Surface Finish | Black, Bright, Customized, Pickled, Polished, Rough Turned |

| Technique | Cold Drawn, Forged, Hot Rolled |

| Form | 310S Stainless Steel Hexagonal Bars, 310S Stainless Steel Pipe, 310S Stainless Steel Square Bar, 310S Stainless Steel Square Bars, 310S Stainless Steel Tube, Annealed 310S Stainless Steel Rods, BA.310S Stainless Steel Round Bars, Centerless Ground 310S Stainless Steel Rods, Cold Drawn 310S Stainless Steel Round Bars, Customized, Forged 310S Stainless Steel Round Bars, Hot-Rolled 310S Stainless Steel Round Bars, Peeled 310S Stainless Steel Rods, Polished 310S Stainless Steel Round Bars |

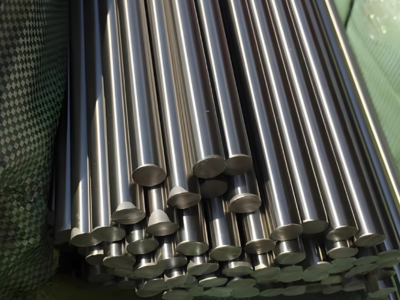

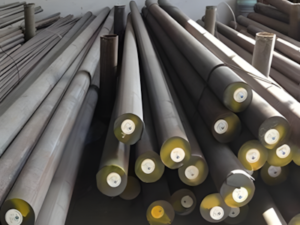

310S Stainless Steel Round Bar | Rod

310S Stainless Steel Round Bar | Rod

- 310S Stainless Steel Round Bar is a cylindrical bar made from grade 310S stainless steel, known for its excellent high-temperature and corrosion resistance. It is typically larger than 1/4 inch in diameter and is used in applications like furnace parts, heat exchangers, and petrochemical equipment.

- 310S Stainless Steel Rod is a smaller diameter cylindrical product, usually less than 1/4 inch, made from grade 310S stainless steel. It offers high-temperature and corrosion resistance, ideal for precise applications in electronics, medical instruments, and detailed machining.

Business Terms

Business Terms

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Korea, United Kingdom, Russian Federation, Iran, Canada, etc.

|

Chemical Compositions

Chemical Compositions

| Element | C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| Content | ≤0.08% | ≤1.50% | ≤2.00% | ≤0.045% | ≤0.030% | 24.0-26.0% | 19.0-22.0% | Balance |

Mechanical Properties

Mechanical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 – 730 MPa | 74,700 – 105,900 psi |

| Yield Strength | ≥205 MPa | ≥29,700 psi |

| Elongation | ≥40% | ≥40% |

| Hardness (Brinell) | ≤217 HB | ≤217 HB |

| Hardness (Rockwell B) | ≤95 HRB | ≤95 HRB |

| Hardness (Vickers) | ≤225 HV | ≤225 HV |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Machining

Machining

- Annealing:

- Temperature: 1040°C – 1150°C (1904°F – 2102°F)

- Process: Heat to the specified range and cool rapidly in air or water to soften the material, improve ductility, and relieve internal stresses.

- Quenching, Tempering, Normalizing: These processes are not suitable for 310S stainless steel due to its austenitic structure, which does not benefit from hardening or grain refinement through these methods.

- Hot Rolling: Heat above recrystallization temperature and roll to size, improving strength and toughness.

- Cold Drawing (Primarily for Rods): Draw at room temperature to reduce cross-section, increasing strength and hardness, ideal for achieving precise dimensions.

- Forging (Primarily for Round Bars): Heat and shape by hammering or pressing to enhance strength and toughness.

- Peeled Turning: Remove the outer surface for a smooth finish and precise dimensions.

- Grinding: Grind to achieve a smooth surface finish and tight tolerances.

Characteristic

Characteristic

Both 310S stainless steel round bars and rods offer high-temperature resistance, excellent corrosion resistance, and good mechanical properties, ensuring durability in harsh conditions.

- 310S Stainless Steel Round Bars:

- High Strength: Suitable for heavy-duty applications.

- Wide Size Range: Available in various diameters for versatile use.

- 310S Stainless Steel Rods:

- Precision Finish: Made with tight tolerances for high accuracy.

- Easy Machinability: Ideal for detailed and complex machining tasks.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

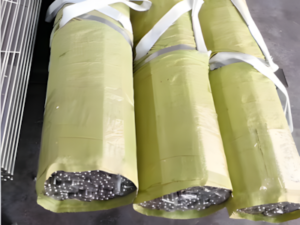

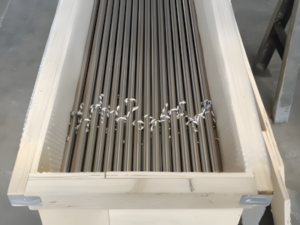

Packing

Packing

- Standard and Enhanced Packaging:

- Bundled with moisture-resistant material and secured with steel straps.

- Enhanced options include wooden crates for added protection, protective end caps, and vacuum-sealed wrapping for superior moisture protection.

- Customizable Services:

- Custom labeling and marking.

- Specific size packaging.

- Additional corrosion protection available upon request.

Why Choose Us

Why Choose Us

- High-Quality Materials: Premium 310S stainless steel round bars and rods for superior durability.

- Precision Manufacturing: State-of-the-art processes ensure exact specifications.

- Custom Solutions: Tailored machining and surface treatments to meet your needs.

- Reliable Delivery: Timely and efficient shipping for your convenience.

- Expert Support: A knowledgeable team is ready to assist with your project.