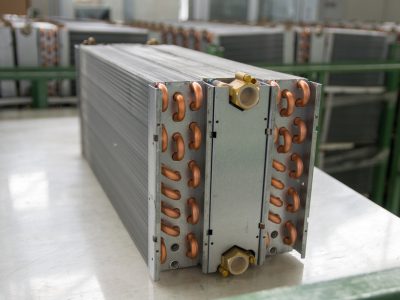

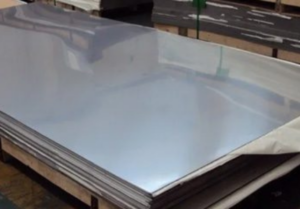

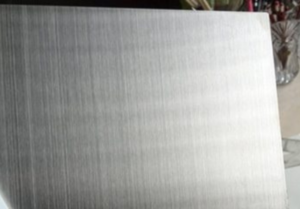

We are a 321 stainless steel sheet, plate, and foil supplier. We offer various types of products, including:

UNS S32100, 1.4541, 321 cold rolled sheet, 321 hot rolled sheet, 321 perforated sheet, 321 polished sheet, 321 hot rolled plate, 321 cold rolled plate, 321 thick plate, 321 thin foil, 321 precision foil, and 321 high-temperature resistant foil.

| Standard | ASTM A215, ASTM A240, ASTM A312 |

|---|---|

| Grade | 0Cr18Ni10Ti, 1.4541, 1Cr18Ni11Ti, SUS323, X6CrNiTi18-10 |

| Length | Customized, Foil:50 m (164 ft) to 100 m (328 ft), Plate:2 m (6.56 ft) to 6 m (20 ft), Sheet: 2 m (6.56 ft) to 3 m (10 ft) |

| Width | 50 mm (1.97 in)to 2 m (78.74 in), Customized |

| Thickness | 2 mm (0.08 in) to 50 mm (2 in), Customized, Foil:0.01 mm (0.0004 in) to 0.1 mm (0.004 in) |

| Surface Finish | 2B, BA, Customized, EP, No. 1, NO. 4, No. 8, Passivation, Pickling |

| Technique | Annealing, Cold Rolling, Customized, Cutting, Hot Rolling, Passivation, Pickling, Polishing |

| Form | Brushed, Coil, Cold Rolled Plate and Sheet, Hot Rolled, Thin Foil |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, United Kingdom, Australia, Canada, India, Korea, etc.

|

| Element | C | Si | Mn | P | S | Cr | Ni | Ti | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.08 max | 0.75 max | 2.00 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 9.00 – 12.00 | 5 * (C + N) min, 0.70 max | 0.10 max | Balance |

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515-720 MPa | 74,700-104,400 psi |

| Yield Strength | 205 MPa | 29,700 psi |

| Brinell Hardness (HB) | 150-220 HB | 150-220 HB |

| Rockwell Hardness (HRC) | 20-30 HRC | 20-30 HRC |

| Vickers Hardness (HV) | 160-220 HV | 160-220 HV |

| Elongation | 40-60% | 40-60% |

| Elastic Modulus | 193-200 GPa | 28,000-29,000 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We ensure your 321 Stainless Steel Sheet, Plate, and Foil arrive in perfect condition:

At SteelPRO Group, we proudly support clients worldwide with timely delivery and dedicated customer service, ensuring your success no matter where you are.