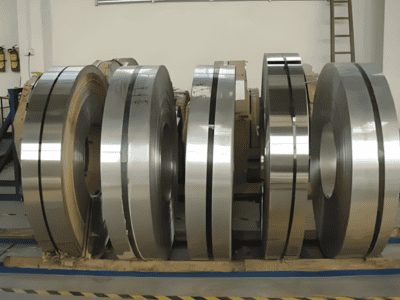

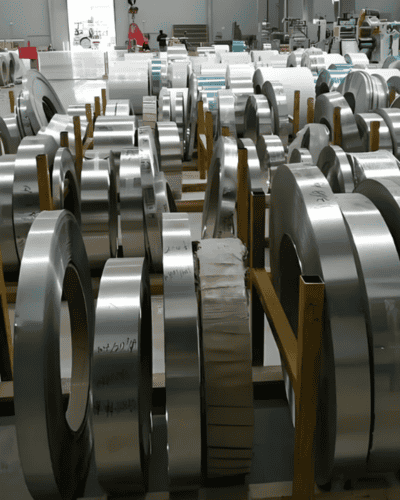

SteelPRO Group is a trusted 201 stainless steel strip factory and 201 strip suppliers & manufacturers. Our services include product customization, fast shipping, technical support, and quality control.

Our products include China 201 stainless steel strip, 201 cold rolled stainless steel strip and 201 j1 stainless steel strip, 201 narrow coil, SUS201 spring strip, 201 precision-cut strips, 201 annealed strip, 1.4372 tempered strip, 201 polished strip, etc.

| Standard | ASTM A666, EN 10088-2, GB/T 24511, JIS G4313 |

|---|---|

| Grade | 1.4372, SUS201, X12CrMnNiN17-7-5, Z12CMN17-07Az |

| Length | Customized |

| Full Width | 5 mm-600 mm (0.2-24 in), Customized |

| Thickness | 0.1 mm-3 mm (0.004-0.12 in), Customized |

| Surface Finish | 2B, 8K, BA, Brushed, Customized, No.1, No.4, Polished |

| Technique | Cold Drawn, Cold Rolled, Hot Rolled |

| Form | 201 narrow coil, Annealed Strip, Coil, Cold rolled strip, etc., Plate, Polished Strip, Precision-cut strips, Sheet, Slit Strips, Spring strip, Tempered strip |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Malaysia, Philippines, Australia, Singapore, Canada, Pakistan, United Kingdom, Germany, Hong Kong, Indonesia, New Zealand, Russian Federation, Thailand, United Arab Emirates, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.15 max | 5.5-7.5 | 1.0 max | 0.06 max | 0.03 max | 16.0-18.0 | 3.5-5.5 | 0.25 max |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 680 – 895 MPa | 99 – 130 ksi |

| Yield Strength | 345 – 515 MPa | 50 – 75 ksi |

| Vickers Hardness | 210 – 250 HV | 210 – 250 HV |

| Brinell Hardness | 200 – 230 HB | 200 – 230 HB |

| Rockwell Hardness | 45 – 55 HRC | 45 – 55 HRC |

| Elongation | 40% | 40% |

| Elastic Modulus | 190 – 210 GPa | 27 – 30 x 10^6 psi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

With our high-standard packaging solutions, you can rest assured that your 201 stainless steel strip will be optimally protected during transportation, ensuring that it arrives undamaged.

When you choose our 201 stainless steel strip, you are choosing a high-quality, reliable and trustworthy product. We are committed to providing high-performance materials to meet your specific needs.