SteelPRO Group is a professional steel product supplier and manufacturer. We provide custom cutting, material testing, precision machining, logistics support and technical guidance to ensure the provision of high-quality steel products that meet the requirements of different industries.

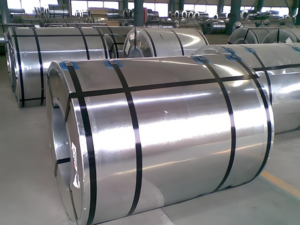

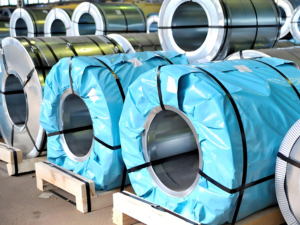

Our products: 17-7PH Cold Drawn Wire, Annealed Wire, Coated Wire, Flat Wire, S17700 Spring Tempered Wire, Welded Wire, Fine Wire, Profiled Wire, 17-7PHCold Rolled Coil, Slit Coil, Polished Coil, 631 Embossed Coil, Hot Rolled Coil, etc.

| Standard | AMS 5528, AMS 5678, ASTM A313, ASTM A693 |

|---|---|

| Grade | 0Cr17Ni7Al, 1.4568, 631, S17700, SUS 631 |

| Length | Customized |

| Diameter | Customized, Wire: 0.25 mm-10 mm (0.01-0.39 in) |

| Thickness | Coil: 0.1 mm-3 mm (0.004-0.12 in), Customized |

| Full Width | Coil: 10 mm-1500 mm (0.39-59.06 in), Customized |

| Surface Finish | 2B, BA, Black, Bright, Coated, etc., Matte, Mill, No.1, No.4 |

| Form | 17-7PH Coil, 17-7PH Wire, Annealed Wire, Bright Finish Wire, Cold Drawn Wire, Edge Conditioned Coil, etc., Flat Wire, Foil, Galvanized Coil, Hot Rolled Coil, Plate, Shaped Wire, Sheet, Slit Coil, Spring Temper Wire, Strip, Tempered coil, Welded Wire |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Canada, Australia, Russian, Federation, Brazil, France, Italy, Thailand, United Kingdom, Bangladesh, Cote D’Ivoire, Denmark, Fiji, Germany, Hong Kong, Mexico, Philippines, Sweden, Turkey, Uganda, etc.

|

| Element | C | Mn | Si | Cr | Ni | Al | P | S |

|---|---|---|---|---|---|---|---|---|

| Content | ≤0.09 | ≤1.00 | ≤1.00 | 16.0-18.0 | 6.5-7.75 | 0.75-1.50 | ≤0.04 | ≤0.03 |

| Property | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 490-685 MPa | 71-99 ksi |

| Yield Strength | ≥ 220 MPa | ≥ 32 ksi |

| Vickers Hardness | 145 HV (typical) | 145 HV (typical) |

| Brinell Hardness | 150 HB (typical) | 150 HB (typical) |

| Rockwell Hardness | 70 HRB (typical) | 70 HRB (typical) |

| Elongation | ≥ 35% | ≥ 35% |

| Elastic Modulus | 190-210 GPa | 27.6-30.4 × 10³ ksi |

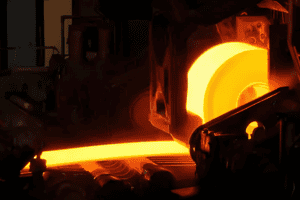

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We prioritize secure and efficient packaging to ensure your 17-7PH stainless steel products arrive in perfect condition.

When choosing a stainless steel supplier, it’s essential to find more than just materials—you need a dependable partner. We are dedicated to being that partner, offering both high-quality products and outstanding service.