S235 Galvanized Steel Pipe/Tube

- Alloy or Not: Non-alloy

- Type: Welded pipe

- Technique: ERW/HFW, EFW, DSAW/SSAW etc.

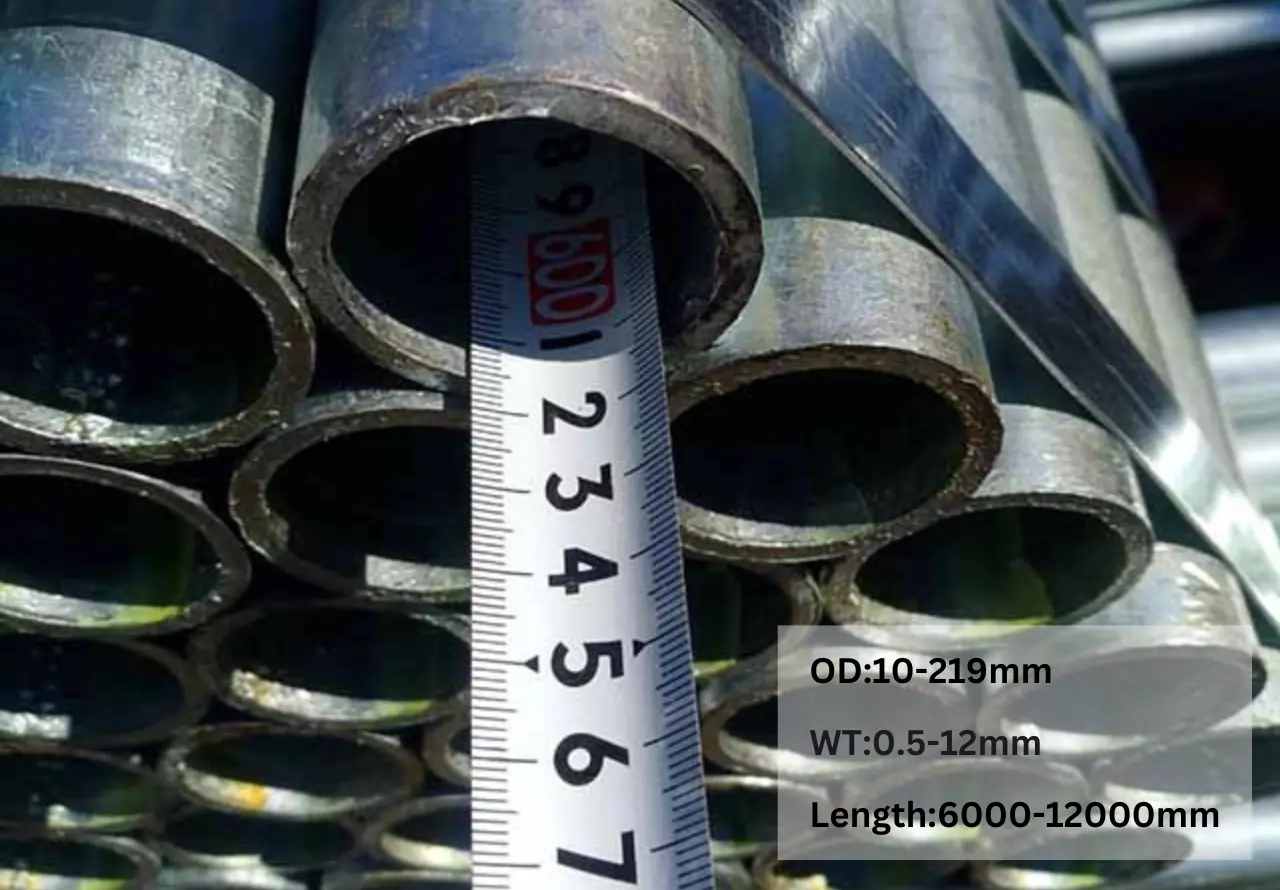

- Size: As requested; details see product parameters

- Section Shape: Round, Square, Rectangular, Oval, etc.

- Galvanization: Hot-dip, Electro, Pre

- Processing Service: Cutting, Punching, Bending, Welding, Decoiling, etc.

- Certification: ISO 9001, CE

- Inspection: SGS, TUV, Factory Inspection

- Origin: Hubei/Henan/Jiangsu, China

- Port: Qingdao, Tianjin, Lianyungang

- MOQ: 5 tons (or as per negotiation)

- Delivery Time: 8-14 Days

- Payment: T/T, L/C

Product Detail

S235 galvanized steel pipe is a reliable choice for construction and industrial applications. The “S235” grade signifies a solid minimum yield strength of 235 MPa, providing ample durability for structural needs.

Its galvanized coating helps resist corrosion, so it stands up well to rust in outdoor and humid environments. This makes it a good fit for applications like scaffolding, bridge supports, and general construction frameworks.

This pipe is also straightforward to work with—suitable for cutting, welding, and other processing methods—so it’s versatile across various projects. While it’s more economical than higher-strength steels, the galvanized layer’s lifespan can vary by environment, so periodic maintenance might be useful in harsher conditions.

Contact us if you are unfamiliar with this product or if you have questions unsolved.

Features

S235 galvanized steel pipes/tubes could bring the following benefits to your project:

- Cost-Effective: Affordable anti-corrosion material with reliable performance.

- Corrosion Resistant: Galvanized coating prevents rust, ideal for humid or corrosive environments.

- Durable: Long service life, reducing maintenance and replacement needs.

- High Strength: Strong tensile strength and load capacity, suitable for structural support.

- Easy to Process: Easily cut, welded, and bent for versatile applications.

- Moderate Weight: Balanced strength-to-weight ratio for easier transport and installation.

Applications

Construction

Structural beams, scaffolding pipes, building frames, roofing supports, etc.

Oil & Gas

Pipeline systems, drilling rig supports, offshore platform structures, fluid transport pipes, etc.

Automotive

Exhaust systems, chassis frames, engine mounts, body reinforcements, etc.

Telecommunication

Antenna masts, signal tower structures, cable trays, data center frameworks, etc.

Marine

Shipbuilding frames, dock reinforcements, cargo handling structures, seawall supports, etc.

Renewable Energy

Solar panel mounts, wind turbine towers, energy storage frames, biomass plant supports, etc.

Product Parameters

| Parameter | Details | |

|---|---|---|

| Standard | EN 10219, EN 10240, EN 10255, DIN 2440, DIN 2444, BS 1387, ASTM A53/A53M, ISO 1461, ASTM A123/A123M, EN 10025, JIS G3442, EN ISO 12944, EN 10305, API 5L, ISO 3183, ect. | |

| Grade | S235JR, S235J0, S235J2 | |

| OD (Outer Diameter) | Pipe | 21.3 – 219 mm; or as requested |

| Tube | 10 – 114 mm; or as requested | |

| WT (Wall Thickness) | Pipe | 2.0 – 12.0 mm; or as requested |

| Tube | 0.5 – 6 mm; or as requested | |

| Length | Pipe | Standard 6m or 12m; or as requested |

| Tube | Standard 6m; or as requested | |

| Tolerance | ±1%, or as requested | |

| Section Shape | Round, Square, Rectangular, Oval, etc. | |

| Galvanization | Hot-Dip Galvanizing, Electro-Galvanizing, Pre-Galvanizing | |

| Zinc Coating | Z30-600 g/m² | |

| Technique | 1) Electric Resistance Welding / High-Frequency Welding (ERW / HFW) ; 2) Electric Fusion Welding (EFW) ; 3) Double Submerged Arc Welding / Spiral Submerged Arc Welding (DSAW / SSAW) |

|

| End | Plain (PE), Beveled (BE), Threaded (TE), Grooved, or as requested | |

| End Protector | Plastic caps, Metal end caps | |

| Pipe Fittings | Elbows, Tees, Couplings, Threaded, Flanges, Caps, etc. | |

| Surface Treatment | 1) Skin Pass, Sand Blasted 2) Pre-painted 3) Galvanized 4) Oiled 5) Passivated 6) 3LPE, FBE, or other anti-corrosive coatings 7) As requested |

|

| Testing Method | Hydrostatic Test, NDT, Tensile Test, Bending Test, Adhesion Test, Coating Thickness Test, etc. | |

| Application | Structural beams, scaffolding pipes, building frames, roofing supports, pipeline systems, offshore platform structures, exhaust systems, chassis frames, antenna masts, signal tower structures, shipbuilding frames, dock reinforcements, cargo handling structures, seawall supports, solar panel mounts, wind turbine towers, etc. | |

| Certification | Approved by ISO 9001, CE | |

| Packaging | Standard seaworthy packing, or as requested | |

Material Specifications

Chemical Composition

| Grade | C | Mn | P | S | Cr | Ni | Cu | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| S235JR | ≤0.17 | ≤1.4 | ≤0.035 | ≤0.035 | ≤0.29 | ≤0.42 | ≤0.55 | ≤0.11 | ≤0.012 |

| S235J0 | ≤0.17 | ≤1.4 | ≤0.03 | ≤0.03 | ≤0.29 | ≤0.42 | ≤0.55 | ≤0.11 | ≤0.012 |

| S235J2 | ≤0.17 | ≤1.4 | ≤0.025 | ≤0.025 | ≤0.29 | ≤0.42 | ≤0.55 | ≤0.11 | – |

*According to EN 10025-2-2019.

Mechanical Properties

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Test Temperature (℃) | Impact Toughness (J) |

|---|---|---|---|---|---|

| S235JR | ≥ 235 | 360 – 510 | ≥ 26 | 20°C | ≥27 |

| S235J0 | 0℃ | ||||

| S235J2 | -20℃ |

Why Choose Us

Consistent Quality

We address your primary quality concerns with S235 galvanized steel pipes/tubes — such as coating uniformity, potential missed spots, and coating adhesion — through continuous hot-dip galvanizing processes & strict control of temperature and timing, non-destructive thickness testing with magnetic gauges, and multi-step-pre-treatment, including acid cleaning and surface preparation, to ensure consistent performance, corrosion resistance, and long-lasting durability across various environments.

Precise Dimensions

We guarantee the dimensional accuracy of our S235 galvanized steel pipes, maintaining tight tolerances within ±0.01mm through precision equipment and ISO 9001-certified processes. Every batch undergoes 100% inspection, with zero deviation complaints in the past 5 years. We ensure smooth project execution without installation delays.

Stable Supply

We have 3 factories with a combined annual capacity of over 500,000 tons. In the event of any unforeseen circumstances, we can coordinate across factories to ensure stable production and on-time delivery.

Stable & Competitive Pricing

We maintain upstream raw material suppliers with price-lock agreements in place to effectively manage material cost fluctuations. Also, considering that our clients may face pressure from market changes, we will try our best to offer reasonable discounts to both new and existing clients.

Secure Packaging & Shipping

Packaging can be customized according to your requirements. We provide transparent, real-time photos of the packaging and loading process for your verification. You can also choose your trusted freight forwarder for transportation to ensure the entire logistics process is secure and reliable.

About Us

Founded in 1999, SteelPRO Group operates three factories with a combined annual production capacity of over 500,000 tons. We specialize in manufacturing a wide range of steel products, including round steel, profiles, plates, and pipes. Our portfolio encompasses low-alloy structural steel, tool steel, special steel, and more.

With strict adherence to global standards such as GB, ASTM, DIN, EN, and JIS, we ensure high-quality products, including heat-treated, machined, and prestressed steel. Our solutions are trusted by customers in diverse industries, and we proudly export to different countries across Europe, North America, and Asia.

At SteelPRO, we are dedicated to delivering tailored steel solutions and growing alongside our dear clients.

Certification

FAQ

What are your prices?

Our prices are subject to change depending on supply and market conditions. For an accurate and up-to-date quote, please contact our sales team directly.

Can you provide relevant documentation?

Yes, we can provide a wide range of documentation, including Certificates of Analysis/Conformance, Insurance, Certificates of Origin, and any other required export documents.

What is the average lead time?

As per mass production, the lead time is 5-20 days after:

1) we have received your deposit; 2) we have received your final confirmation on your orders.

If our lead time doesn’t meet your deadlines, please contact our sales directly in advance in case of any potential issues. We will try to accommodate your needs in all cases, and we are able to do so in most cases.

Can you provide free samples?

Yes, we can provide free samples for quality evaluation. However, shipping costs are generally covered by your company.

Can I visit your factory?

Of course! We welcome customers to visit our factory! Please contact us in advance to arrange a convenient time for your visit, and we will gladly organize a tour and provide any necessary information to ensure a productive visit.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming