CGCC | CGCH Prepainted Galvanized Steel PPGI & Coil

CGCC | CGCH Prepainted Galvanized Steel PPGI & Coil

Galvanized steel manufacturer and supplier SteelPRO Group offers top-quality CGCC and CGCH pre-coated galvanized steel (PPGI) and coils that can be customized for a variety of applications. Our PPGI products offer excellent corrosion resistance and vibrant finishes, making them ideal for roofing, wall cladding, and automotive components. Coils are also available in a variety of coated or bare colors. We offer custom solutions and expert support to ensure you get the right material for your needs. Whether you require specific dimensions, unique coatings, or timely delivery, SteelPRO Group is your reliable partner for all your steel solutions.

- Standards: ASTM A755, ISO 14200, JIS G3312, ASTM A924, ISO 12944, etc.

- Grades: CGCC, CGCH, Q195, Q215, Q235, Q345, S235, S355, SPCC, etc.

- Technology: Cold rolling, Electrogalvanizing, Zinc Plating, Hot-dip Galvanizing, Hot rolling, etc.

- Substrate: Hot rolled steel or cold rolled steel

- Type: Coated, embossed and printed boards

- Certification: ISO 9001, CE

CGCC | CGCH Prepainted Galvanized Steel PPGI & Coil

CGCC | CGCH Prepainted Galvanized Steel PPGI & Coil

Product Specifications

Product Specifications

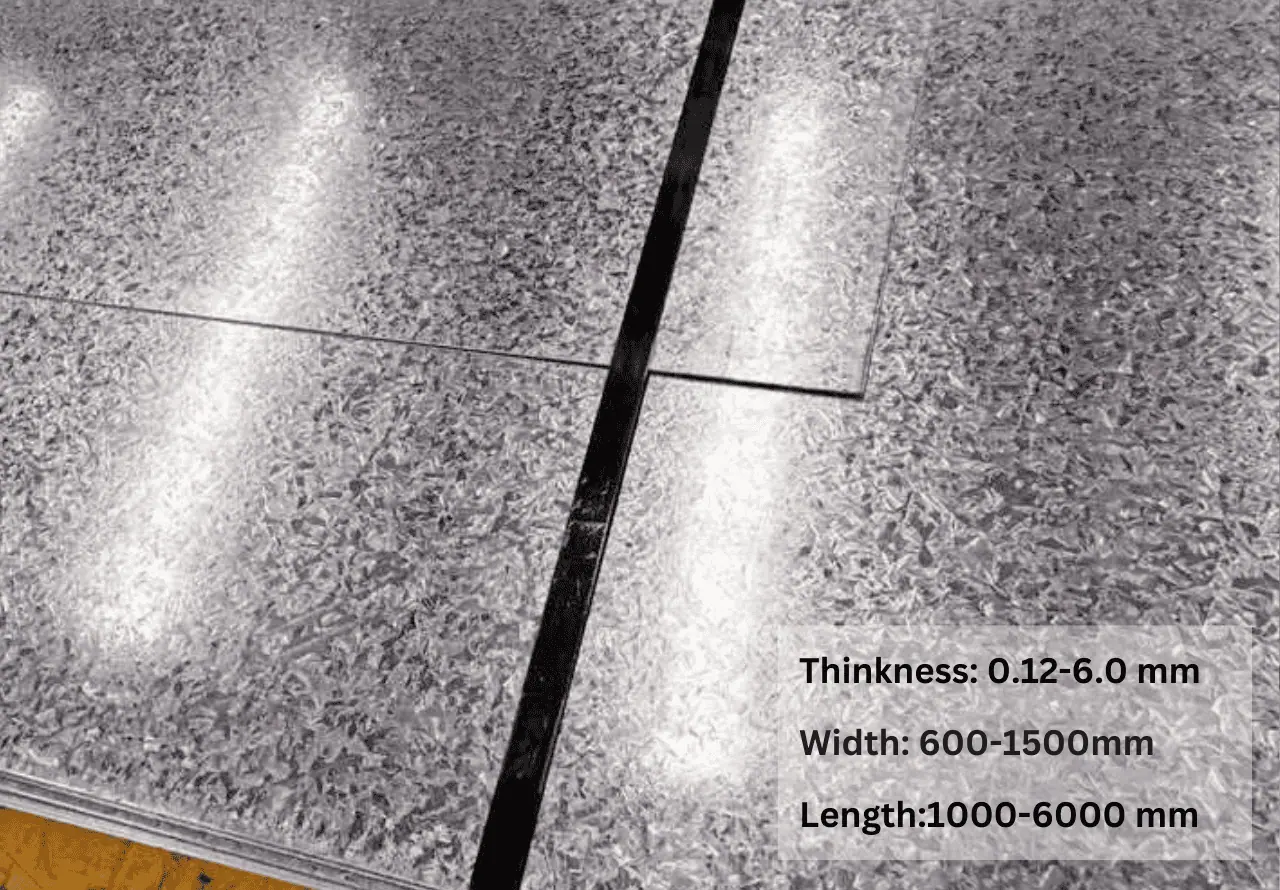

| Product Name | CGCC | CGCH Color coated galvanized steel PPGI & Coil |

| Thickness | 0.1mm-5mm, Customized |

| Width | 600mm – 2000mm, Customized Regular Width: 914mm, 1000mm, 1219mm, 1220mm, 1250mm |

| Length | Customized |

| Coil Inner | 508mm – 610mm, Customized |

| Zinc Layer | 30g – 275g/m² |

| Coating Thickness | Top Coating: 15μm-25μm;

Back Coating: 5μm-20μm. |

| Surface Color | According to required RAL. |

| Coating Material | Polyester (PE), Silicone Polyester (SMP), High Durable Polyester (HDP), Fluoropolymer (PVDF) |

| Painting structure | No coating, single-sided coating, double-sided coating |

| Spangle | Big, regular, mini, and zero spangles |

| Surface Treatment | anti-finger print/skin pass/oiled/dry/chromated/Embossed/Lamination |

| Hardness | Soft (normal), hard, full hard(G300-G550) |

| T Bend | ≧ 3 T |

| Reverse Impact | ≧ 9 J |

| Salt Spray Resistance | ≧ 500 H |

| Anti-MEK Wiping | ≧ 100 Times |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | CGCC | CGCH |

|---|---|---|

| Carbon (C) | ≤ 0.12% | ≤ 0.20% |

| Manganese (Mn) | ≤ 0.60% | ≤ 1.50% |

| Phosphorus (P) | ≤ 0.04% | ≤ 0.04% |

| Sulfur (S) | ≤ 0.04% | ≤ 0.05% |

| Silicon (Si) | ≤ 0.50% | ≤ 0.50% |

| Aluminum (Al) | – | ≤ 0.10% |

| Chromium (Cr) | – | ≤ 0.10% |

Mechanical properties

Mechanical properties

| Property | CGCC PPGI | CGCH PPGI |

|---|---|---|

| Tensile Strength (MPa) | 270 – 400 | 300 – 450 |

| Yield Strength (MPa) | 180 – 250 | 220 – 350 |

| Elongation (%) | ≥ 20 | ≥ 20 |

| Vickers Hardness (HV) | 70 – 120 | 80 – 150 |

| Brinell Hardness (HB) | 80 – 130 | 90 – 160 |

| Rockwell Hardness (HRB) | 50 – 90 | 60 – 100 |

| Elastic Modulus (GPa) | ~200 | ~210 |

Industries & Applications

Industries & Applications

Both CGCC and CGCH PPGI and coil are versatile materials, ideal for a wide range of applications, delivering excellent durability and aesthetic options across various industries.

CGCC Applications

- Home Appliances: Used in the production of refrigerators, washing machines, and air conditioners, offering both protection and aesthetic appeal.

- Interior Decoration: Ideal for wall panels and furniture due to its attractive finish and resistance to corrosion.

- Building Materials: Employed for interior partitions and false ceilings, providing functional and design versatility.

- Automotive Parts: Utilized in non-structural components for its lightweight properties and rust resistance.

CGCH Applications

- Roofing and Cladding: Commonly used for roofing sheets and wall panels in residential and commercial buildings, known for its durability and weather resistance.

- Infrastructure: Applied in constructing bridges, railway stations, and other public structures requiring enhanced corrosion protection.

- Automotive Industry: Suitable for structural components and body panels in vehicles, providing strength and long-lasting protection against rust.

- Industrial Applications: Used in manufacturing storage tanks, silos, and agricultural equipment, designed to withstand harsh environmental conditions.

Other Infomation

Other Infomation

When you are considering whether to choose CGCC or CGCH, it is important to understand the difference between these two grades.

Corrosion resistance:

- CGCC uses cold galvanizing process, and the galvanizing layer is relatively thin, so it is more suitable for indoor environments or places with mild corrosion. For example, home appliances and interior decoration are very suitable.

- CGCH uses hot-dip galvanizing process, and the galvanizing layer is thicker, providing stronger corrosion protection, suitable for outdoor or harsh environments, such as buildings, infrastructure and transportation facilities.

Strength and durability:

- CGCC has lower strength and durability and is suitable for light applications.

- CGCH has higher mechanical strength and durability, can withstand greater loads, and is suitable for heavy structures and more demanding conditions.

Cost:

- CGCC is usually less expensive and suitable for projects with limited budgets.

- CGCH is slightly more expensive due to its higher performance and thick galvanizing layer, but its long-term cost-effectiveness is often better.

Recommendation

If your project is mainly indoors, such as home appliances, wall decoration or light building materials, CGCC may be a better choice. It is relatively low-cost, has a wide range of color options, and is sufficient for daily use.

However, if you need to use it outdoors or in harsher environments, such as building roofs, infrastructure, or automotive parts, then CGCH will be more suitable. Its zinc coating is thicker, has stronger corrosion resistance, and can maintain better durability in harsh conditions.

Our Inventory

Our Inventory

With state-of-the-art production lines and strong partnerships with leading suppliers, SteelPRO Group ensures a continuous supply of high-quality products to meet a variety of customer needs. Our facilities have a large production capacity, allowing us to quickly fulfill large orders without compromising quality. This commitment to excellence has earned us a reputation as a reliable partner for businesses seeking durable and beautiful steel solutions.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

At SteelPRO Group, we understand the importance of secure and efficient packaging to ensure our products reach you in perfect condition. Our packing process involves using durable materials and protective methods tailored to the specific needs of each product. We utilize customized pallets, shrink-wrapping, and sturdy containers to safeguard against damage during transit. Additionally, our team carefully inspects every package before shipment, ensuring that all items are accurately labeled and securely packed. With our commitment to quality in both products and packaging, you can trust that your order will arrive safely and on time.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

Can I customize the size and color of my steel products?

Yes, we offer custom options in size, color, and finish to meet your specific project requirements. Please contact us for more details.

How does SteelPRO Group ensure product quality?

From raw materials to final inspection, we implement stringent quality control measures at every stage of the production process, ensuring that our products meet the highest industry standards.

What makes SteelPRO Group different from other manufacturers?

Our commitment to innovation, quality, and customer service sets us apart in the market. We focus on sustainable practices and continuous improvement to provide reliable steel solutions tailored to our customers’ needs.

How should PPGI coils be stored after purchase?

It is recommended that PPGI coils be stored in a dry, well-ventilated area away from moisture and direct sunlight. Proper storage will help maintain the quality and finish of the steel.

Do your products meet international standards?

Yes, our PPGI products meet a variety of international standards, including ASTM, ISO, and JIS, ensuring that you receive reliable and high-quality materials.

Does SteelPRO Group provide technical support or consulting for projects?

Of course! Our experienced team can provide technical support and consultation to help you select the right products and ensure your project is successful.

CONTACT

Certificates and Cooperation

Certificates and Cooperation