SPCC Galvanized Steel Sheet | Plate

SPCC Galvanized Steel Sheet | Plate

SteelPRO Group is SPCC galvanized steel sheets manufacturer and supplier, providing a wide range of hot-dip galvanized and electro-galvanized steel sheets, as well as coils, pipes, roofing panels, etc., suitable for industries such as construction, home appliances, automobiles and electronics. We provide customized services to ensure that the steel sheets meet the highest industry standards. We provide customers with a full range of pre-sales and after-sales technical support to assist in product selection and application optimization, and help projects succeed.

- Standard: JIS G 3302, ASTM A653, EN 10142, GB/T 2518, etc.

- Grades: DC01 + Z, CS Type B, St12, Q195, Q215, SPCC, etc.

- Technology: Cold rolled, hot dip galvanized, electro galvanized

- Certification: ISO 9001, CE

SPCC Galvanized Steel Sheet | Plate

SPCC Galvanized Steel Sheet | Plate

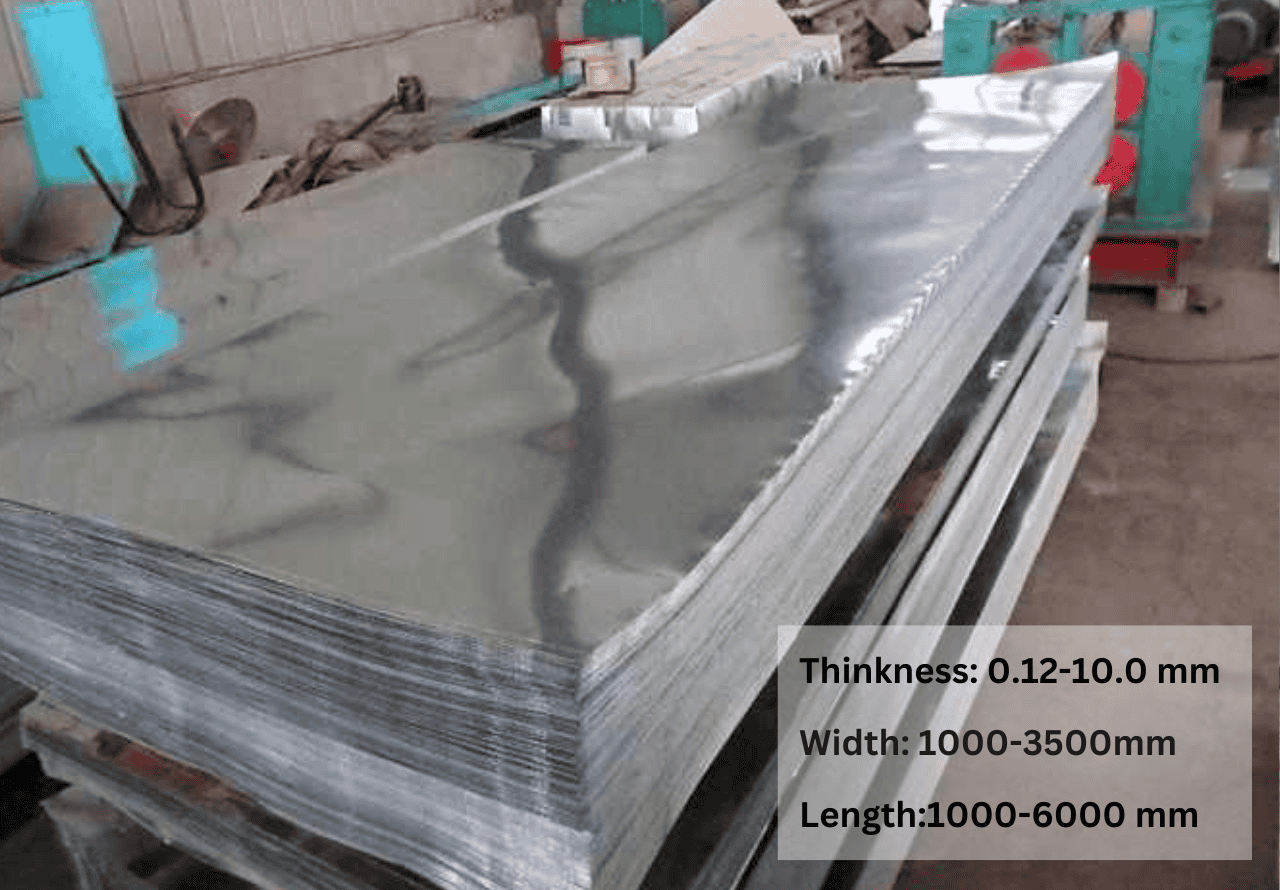

Product Specifications

Product Specifications

| Product Name | SPCC Galvanized Steel Sheet | Plate |

| Thickness | 0.12mm – 10.0mm, Customized |

| Width | Regular: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, Customized |

| Length | 1000mm – 6000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, Z20-Z29,Z81-Z120, etc. |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination / PPGI |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Edge | Mill edge, Cut edge |

| Hardness | Soft Hard(<60)

Medium Hard(60-85) Full Hard(85-95) |

| Test | Zinc Coating Thickness Test, Salt Spray Test, Adhesion Test, Tensile Test, Bend Test, etc. |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Sulfur (S) | Phosphorus (P) |

|---|---|---|---|---|

| Content (%) | ≤ 0.12 | ≤ 0.50 | ≤ 0.045 | ≤ 0.040 |

Mechanical properties

Mechanical properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 – 410 |

| Yield Strength (MPa) | 140 – 240 |

| Elongation (%) | ≥ 28 |

| Vickers Hardness (HV) | 85 – 100 |

| Brinell Hardness (HB) | 70 – 95 |

| Rockwell Hardness (HRB) | 50 – 65 |

| Elastic Modulus (GPa) | ~ 210 |

Industries & Applications

Industries & Applications

- Automotive Industry: Used in car body panels, structural parts, and interior components due to its excellent corrosion resistance and moderate strength.

- Home Appliances: Commonly used for refrigerator, washing machine, and air conditioner casings, as it provides a smooth surface finish and corrosion protection.

- Construction: Applied in roofing, wall panels, and structural supports, especially in environments where rust resistance is essential.

- Electrical and Electronic Equipment: Used for enclosures, control panels, and cabinets due to its conductive properties and durability.

- Furniture: Ideal for metal furniture frames and shelves that require a polished, corrosion-resistant surface.

- HVAC Systems: Utilized in ductwork, ventilation systems, and other HVAC components due to its durability and resistance to moisture.

Other Infomation

Other Infomation

We provide a variety of processing services for SPCC galvanized steel sheets to ensure that the products can perfectly meet the needs of customers’ projects.

1. Cutting service

We use precision cutting equipment to perform high-precision cutting of steel sheets according to the dimensions specified by customers. It supports conventional straight-line cutting and laser cutting of complex shapes. The edges after cutting are neat and smooth, reducing the need for secondary processing and ensuring efficient installation.

2. Forming service

SPCC steel sheets are very suitable for forming processing due to their excellent ductility. We provide a variety of forming processes such as bending, stretching, stamping, and rolling. Whether it is a simple bending process or a more complex multiple forming process, we can ensure that the product maintains high surface quality, avoids cracks and scratches, and adapts to various structural and design requirements.

3. Welding service

We provide professional welding services, including spot welding, laser welding, gas shielded welding, etc., to ensure the integrity of the galvanized layer and reduce thermal damage. Our welding technology prevents damage to the coating while ensuring firmness, which is suitable for project needs that require structural connection or assembly.

Our Inventory

Our Inventory

SteelPRO Group has advanced automated production equipment and a strict quality control system to ensure that every steel plate meets the highest industry standards. From raw material procurement to production and processing, each step is carefully tested and optimized to ensure product stability and consistency. Our team focuses on innovation and continuous improvement, able to meet diverse market needs and maintain strong production efficiency and delivery capabilities.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc. Each product optimizes strength, ductility and corrosion resistance according to specific application characteristics, and can meet the needs of a variety of usage scenarios from complex forming to heavy-duty structures.

Packing

Packing

Our packaging design ensures that the product maintains high quality during transportation and storage. All galvanized steel sheets are packed in special moisture-proof and impact-proof packaging materials, and are bundled and reinforced according to customer requirements. We provide customized packaging solutions to ensure that each batch of products arrives intact and safely during transportation to you.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What is the lifespan of SPCC galvanized steel sheets in different environments?

Our SPCC galvanized steel sheets are designed for durability, typically lasting 10-20 years in moderate conditions and 5-10 years in harsher, outdoor environments. With proper maintenance and coating, their lifespan can be extended even further.

How does SPCC steel perform in terms of corrosion resistance?

SPCC galvanized steel offers excellent corrosion resistance thanks to its high-quality zinc coating, which protects against rust and corrosion in humid or mildly corrosive environments, making it ideal for indoor and certain outdoor applications.

Are there different finish options available for SPCC steel sheets?

Yes, we offer a range of finish options, including matte, gloss, and custom coatings, allowing you to match the desired aesthetic and functional requirements of your project.

What quality standards does SteelPRO Group follow in production?

SteelPRO Group adheres to international quality standards, including JIS, ASTM, and EN certifications, ensuring that all products meet rigorous safety and durability benchmarks.

How quickly can SteelPRO Group fulfill large-volume orders?

Thanks to our advanced production capabilities and efficient logistics, we can fulfill large orders promptly, with lead times adjusted based on the order size and specifications.

Does SteelPRO Group offer sustainable or eco-friendly production options?

Yes, we are committed to sustainable practices, including eco-friendly material sourcing and waste reduction, to support both environmental responsibility and industry innovation.

CONTACT

Certificates and Cooperation

Certificates and Cooperation