Bending

SteelPRO Group offers seven or more steel bending techniques, providing precise, cost-effective solutions for all your project needs. From complex curves to tight bends, we ensure fast, high-quality results tailored to your specifications.

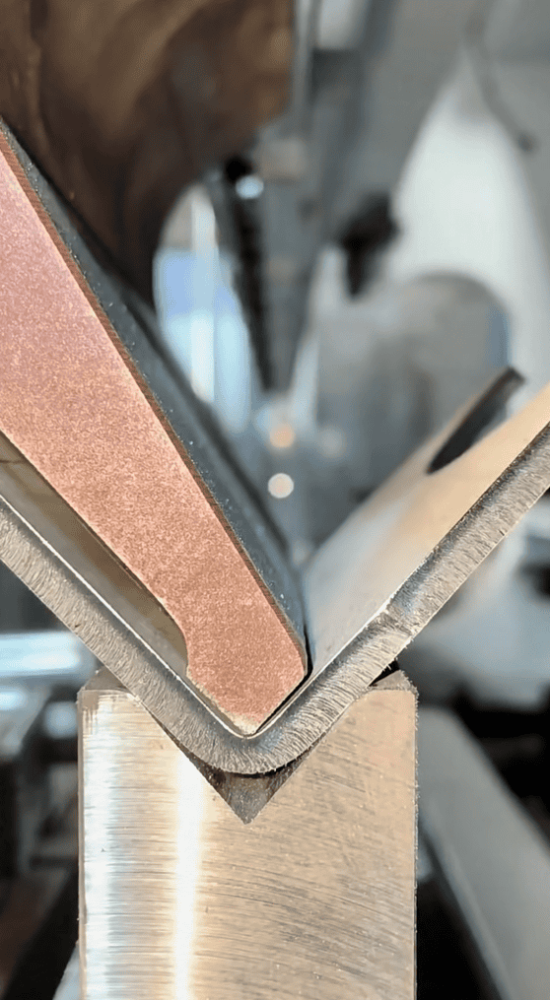

1. V-Bending

Advantages:

- Offers high precision, works with various sheet metal thicknesses and angles, and produces tight bends for sharp corners.

Common Subgroups:

- Bottoming: Achieves a precise angle by pressing the material into the die fully.

- Coining: Uses higher pressure to deform the material precisely into the die, ensuring greater accuracy.

Application Fields:

- Used in automotive, appliance manufacturing, and construction for creating brackets, panels, and enclosures.

Important Note: Not suitable for high-strength steel, thick plates, or brittle materials such as high-carbon steel and cast iron.

2. Air Bending

Advantages:

- Provides flexibility with fewer tool changes, uses lower force, and allows multiple angles with the same tool.

Common Subgroups:

- Three-point bending: A form of air bending used to create bends at multiple points along the material.

Application Fields:

- Commonly used in sheet metal fabrication, aerospace, and furniture production for parts that require complex angles.

Important Note: Not recommended for thick, high-strength steel or brittle materials like high-carbon steel and cast iron due to potential cracking.

3. U-Bending

Advantages:

- Efficient for mass production, forms U-shaped bends in one operation, and delivers consistent results.

Common Subgroups:

- Edge bending: A variation that bends the edges of sheets to form U-shapes.

Application Fields:

- Widely used in automotive components, structural framing, and furniture manufacturing for channel sections and frames.

Important Note: Not suitable for brittle materials or high-strength steel due to the risk of fracture during the bending process.

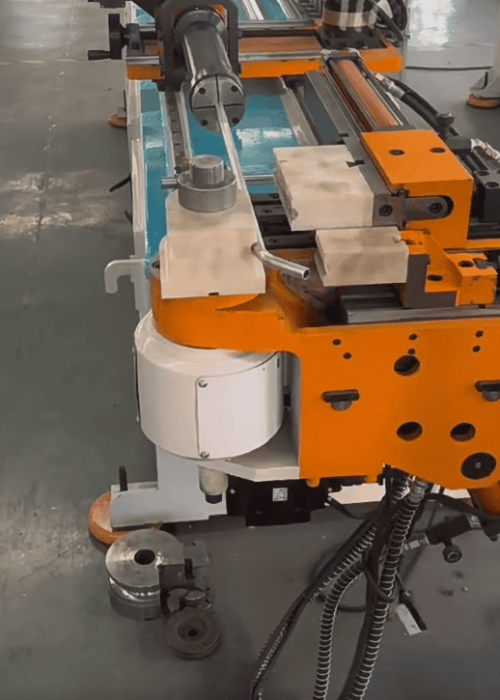

4. Pipe Bending

Advantages:

- Ensures smooth, wrinkle-free bends for hollow pipes, maintains the pipe’s integrity, and allows flexible radii and angles.

Common Subgroups:

- Rotary draw bending: Allows for tighter radius bends with precision.

- Mandrel bending: Uses an internal support to prevent collapse or deformation of the pipe during bending.

Application Fields:

- Commonly used in plumbing, HVAC systems, automotive exhaust systems, and construction for creating pipelines, handrails, and frames.

Important Note: Not appropriate for thick-walled or brittle materials such as cast iron and high-carbon steel, which are prone to cracking.

5. Step Bending

Advantages:

Creates large, gradual curves, ideal for thin materials, and is cost-effective with fewer specialized tools required.

Common Subgroups:

Multi-step bending: A process where multiple small bends are made in succession to form a gradual curve.

Application Fields:

Often used in furniture production, architectural structures, and aerospace to form large, complex curves.

Important Note: Not suitable for high-strength steel, thick plates, or brittle materials like cast iron, as the gradual bending process can cause fractures.

Our Equipment Bending Range

We can not only process the following specifications, but also bending for your customized special specification steel.

| Material Type | Thickness Range | Width Range | Length Range |

|---|---|---|---|

| Bar/Rod | 1 mm to 50 mm | 5 mm to 100 mm | Up to 6 m |

| Tube/Pipe | 1 mm to 20 mm | 10 mm to 300 mm | Up to 12 m |

| Plate/Sheet | 0.5 mm to 25 mm | 100 mm to 3000 mm | Up to 6 m |

Related Bending Processes

Bottoming: The material is pressed fully into the die, creating precise angles with little spring-back. It’s ideal for sharp corners.

Coining: High pressure forces the material into the die for tight, accurate bends. This method minimizes spring-back.

Rolling: The material is bent gradually using rollers to form large curves, arcs, or cylinders. It’s used in structural and architectural work.

Hemming: The edge of the metal is folded onto itself for strength or aesthetics. It’s often used in automotive and appliance parts.

Why Choose Us for Steel Bending

- Cost-Efficient

Our bending methods, like V-Bending and Air Bending, minimize waste and reduce the need for extra processing, cutting costs. - Competitive Pricing

We offer competitive rates across small and large-scale orders, delivering high-quality results at the best value. - Fast Turnaround

With flexible techniques, we provide quick delivery even for complex designs, without sacrificing quality. - High Quality

Our precision-focused bending, backed by strict quality controls, ensures accurate, durable parts ready for immediate use.

Choosing us guarantees cost savings, speed, precision, and consistent quality for your projects.

FAQ

Is it better to bend steel cold or hot?

Cold bending is typically better for precision, while hot bending is used for thicker materials or complex shapes.

Does heating steel make it easier to bend?

Yes, heating steel softens it, making bending easier, especially for thick or high-strength materials.

How much psi to bend steel?

The required PSI varies, but typically, bending steel can range from 30,000 to 60,000 PSI depending on thickness and grade.

How thin does steel need to be to bend?

Steel can bend at thicknesses as thin as 0.5 mm, but thinner sheets are more prone to deformation or cracking.

How do you ensure precision and consistency in large runs?

We use advanced equipment with strict quality controls to maintain accuracy across all parts in large production runs.

Can you handle complex shapes like large curves or multiple angles?

Yes, we specialize in complex bends, including large curves and multi-angle designs.

Which bending methods are best for high-volume with minimal tool changes?

Air bending and step bending are ideal for high-volume production due to flexibility and minimal tool changes.

How do you prevent cracking or deformation in delicate materials?

We use controlled bending techniques and support methods like mandrel bending to protect delicate materials.