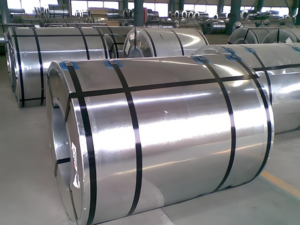

SteelPRO Group is a stainless steel manufacturer and supplier with a professional 201 stainless steel coil factory. We provide services including product customization, fast delivery, technical support, and quality assurance.

We offer China 201 stainless steel coil, AISI cold rolled 201 stainless steel coil, hot rolled 201 stainless steel coil, 201 BA stainless steel coil, 201 No.1 stainless steel coil, 1.4372 slit coil, SUS201 annealed coil, and 201 2B stainless steel coil, etc.

| Standard | ASTM A240, EN 10088-2, GB/T 4237, JIS G4304 |

|---|---|

| Grade | 1.4372, SUS201, X12CrMnNiN17-7-5, Z12CMN17-07Az |

| Full Width | 600 mm-2000 mm (24-78.74 in), Customized |

| Thickness | 0.3 mm-6 mm (0.012-0.24 in), Customized |

| Length | Customized |

| Surface Finish | 2B, 8K, BA, Brushed, Customized, HL, No.1, No.4, Polished |

| Technique | Cold Drawn, Cold Rolled, Hot Rolled |

| Form | Annealed coil, Cold Rolled Coil, etc., Hot Rolled Coil, Pickled coil, Plate, Polished Coil, Sheet, Slit Coil, Strip |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Canada, Australia, Malaysia, Philippines, Singapore, Indonesia, United Kingdom, France, New Zealand, United Arab Emirates, Algeria, Cameroon, Germany, Ghana, Hong Kong, Israel, Italy, Jordan, Kenya, Kuwait, Mexico, Morocco, Netherlands, Nigeria, Norway, Pakistan, Qatar, Russian Federation, Saudi Arabia, Spain, Thailand, Tunisia, Uganda, Ukraine, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.15 max | 5.5-7.5 | 1.0 max | 0.06 max | 0.03 max | 16.0-18.0 | 3.5-5.5 | 0.25 max |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515 – 750 MPa | 75 – 109 ksi |

| Yield Strength | 275 – 450 MPa | 40 – 65 ksi |

| Vickers Hardness | 210 – 240 HV | 210 – 240 HV |

| Brinell Hardness | 95 – 210 HB | 95 – 210 HB |

| Rockwell Hardness | 20 – 28 HRC | 20 – 28 HRC |

| Elongation | 40% | 40% |

| Elastic Modulus | 200 GPa | 29 x 10^6 psi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

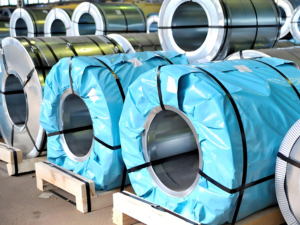

We understand that the quality of your 201 stainless steel coil isn’t just about what’s inside—it’s also about how it arrives at your doorstep. We take extra care in our packing to ensure safe and secure transport, minimizing the risk of damage during shipping.

Our extensive industry experience and commitment to excellence ensure that you receive the best in both material quality and customer service.