SteelPRO Group is a leading steel supplier and manufacturer, supplying OEM 201 stainless steel pipe and CE certification 201 stainless steel pipe to the global market. Our services include processing, cutting, surface treatment and product customization.

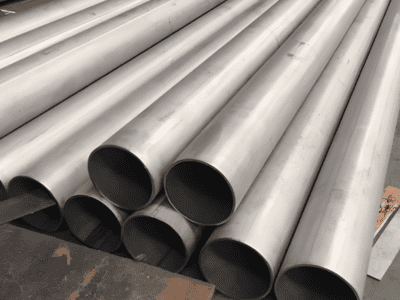

Our products include China 201 stainless steel pipe, China 201 seamless stainless steel pipe, 201 round pipe, 1.4372 square pipe, cold-drawn tubing, SUS201 heat-exchanger tubing, 201 welded pipe, 201 polished tubing, hot rolled tubing.

| Standard | ASTM A249, ASTM A269, ASTM A312, ASTM A554, EN 10296-2 |

|---|---|

| Grade | 1.4372, SUS201, X12CrMnNiN17-7-5, Z12CMN17-07Az |

| Length | 1000 mm-6000 mm (39.37-236.22 in), Customized |

| OD | 6 mm-500 mm (0.24-19.7 in), Customized |

| WT | 0.5 mm-10 mm (0.02-0.39 in), Customized |

| Shape | Customized, Flat Oval, Hexagonal, Oval, Rectangular, Round, Square, U-Shaped |

| Surface Finish | 2B, 8K, BA, Customized, HL, No.1, No.4, Pickling, Polished |

| Form | Cold rolled pipe, Cold-Drawn Tubing, etc., Heat-exchanger tubing, Hot rolled tubing, Polished Tubing, Round Pipe, Seamless Pipe, Square Tube, Tube, Welded Pipe |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Australia, Canada, Malaysia, Singapore, Philippines, India, United Kingdom, Hong Kong, Indonesia, New Zealand, Russian Federation, Thailand, United Arab Emirates, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.15 max | 5.5-7.5 | 1.0 max | 0.06 max | 0.03 max | 16.0-18.0 | 3.5-5.5 | 0.25 max |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 520 – 750 MPa | 75 – 108 ksi |

| Yield Strength | 275 – 380 MPa | 40 – 55 ksi |

| Vickers Hardness | 140 – 200 HV | 140 – 200 HV |

| Brinell Hardness | 160 – 210 HB | 160 – 210 HB |

| Rockwell Hardness | 80 – 90 HRB | 80 – 90 HRB |

| Elongation | 40% | 40% |

| Elastic Modulus | 200 GPa | 29 x 10^6 psi |

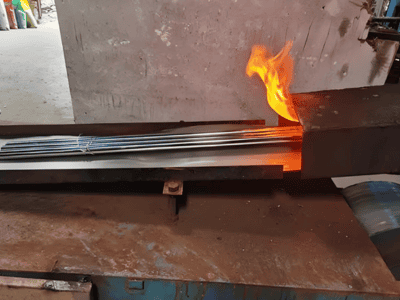

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

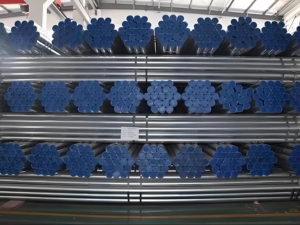

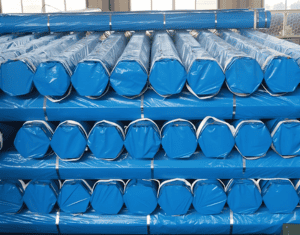

We believe that proper packaging is key to ensuring the safe and secure delivery of our 201 Stainless Steel Pipe & Tubing.

When it comes to 201 Stainless Steel Pipe & Tubing, choosing the right supplier makes all the difference.