303 Stainless Steel Round Bar & Flat Bar

303 Stainless Steel Round Bar & Flat Bar

SteelPRO Group is a leading 303 stainless steel bar manufacturer, 303 stainless steel hexagon bar supplier, and 303 stainless steel flat bar supplier. We own a 303 stainless steel square bar factory, provide custom cutting, precision machining and technical support.

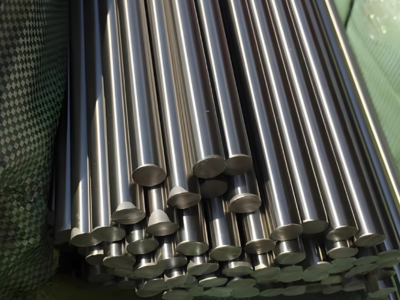

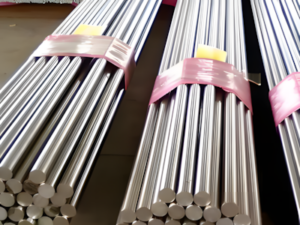

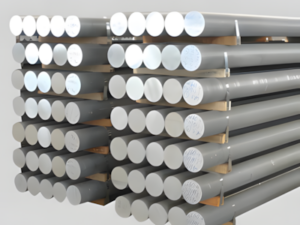

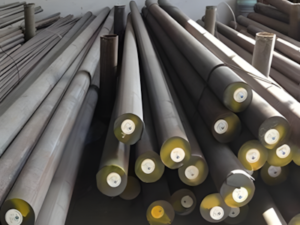

Our Products: 303 hot rolled round bar, cold drawn round bar, 1.4305 polished round bar, 303 turned round bar, SUS303 annealed flat bar, 303 finished rolled flat bar, 303 precision flat bar, 303 cut to size flat bar.

| Standard | ASTM A276, ASTM A582, EN 10088-3, JIS G4304 |

|---|---|

| Grade | 1.4305, 303S31, SUS303, X8CrNiS18-9 |

| Length | 2000 mm-6000 mm (78.74-236.22 in), Customized |

| Diameter | Customized, Round Bar: 5 mm to 500 mm (0.2-19.7 in) |

| Thickness | Customized, Flat Bar: 3 mm-60 mm (0.12-2.4 in) |

| Full Width | Customized, Flat Bar: 20 mm-200 mm (0.8-8 in) |

| Surface Finish | Brushed, Customized, Ground, Mirror, Pickling, Polishing, Turned |

| Form | 303 Stainless Steel Rod, Annealed Round Bar, Bar, Bar rod, Bright flat bar, Cold drawn flat bar, Cold Drawn Round Bar, Cold rolled flat bar, etc., Finished rolled flat bar, Forged flat bar, Hot Rolled Round Bar, Peeled round bar, Polished Round Bar, Shear edge flat bar, Turned round bar |

303 Stainless Steel Round Bar & Flat Bar

303 Stainless Steel Round Bar & Flat Bar

- 303 Round Bar is an austenitic stainless steel. It has excellent machinability, good corrosion resistance, and moderate strength. The bar in the annealed condition is non-magnetic and has good wear resistance. It is commonly used to make bolts, shafts, gears, and fasteners in industries such as automotive, aerospace, and precision engineering that require easy machining.

- 303 Flat Bar is a rectangular austenitic stainless steel. It has high machinability, good corrosion resistance, and easy formability. The flat bar is also non-magnetic and has good strength in mild environments. It is widely used in the manufacture of brackets, supports, and mounting plates in machinery, electrical equipment, and construction that require easy cutting and fabrication.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, India, United Kingdom, Australia, Germany, Indonesia, Mexico, Netherlands, Russian Federation, Brazil, Malaysia, Philippines, South Africa, Indonesia, Singapore, Taiwan, Vietnam, Turkey, France, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Chromium (Cr) | Nickel (Ni) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

| Composition (%) | 17.0 – 19.0 | 8.0 – 10.0 | ≤ 0.15 | ≤ 2.0 | ≤ 1.0 | ≤ 0.20 | 0.15 – 0.35 |

Mechanical Properties

Mechanical Properties

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 700 – 900 MPa | 101.5 – 130.5 ksi |

| Yield Strength | 500 – 700 MPa | 72.5 – 101.5 ksi |

| Brinell Hardness (HB) | 200 – 250 HB | 200 – 250 HB |

| Rockwell Hardness (HRC) | 30 – 40 HRC | 30 – 40 HRC |

| Vickers Hardness (HV) | 230 – 300 HV | 230 – 300 HV |

| Elongation | 10% – 15% | 10% – 15% |

| Elastic Modulus | 210 GPa | 30 x 10³ ksi |

Heat Treatment

Heat Treatment

- Annealing: Heating to 1010°C to 1120°C, then cooling rapidly (usually quenching in air or water).

- Stress Relieving: Heating the material to 500°C to 750°C, maintaining for a certain period of time, and then letting the material cool slowly.

- Solution Treatment: Heating the material to 1010°C to 1120°C. Keeping for a period of time, then cooling rapidly (usually quenching in water or air).

- Quenching and Tempering are not applicable to 303 stainless steel.

- Precipitation Hardening & Nitriding are not applicable to 303 stainless steel.

Characteristic

Characteristic

303 round bars and flat bars have excellent machinability and good corrosion resistance, suitable for mildly corrosive environments. Due to the addition of sulfur, although they have high machinability, they have poor weldability and are not suitable for welding applications. Round bars are more suitable for manufacturing shafts and rotating parts, while flat bars are suitable for making flat structural parts such as brackets and frames.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

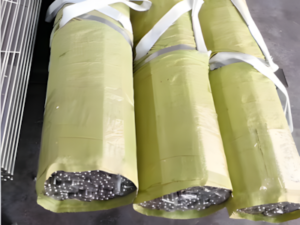

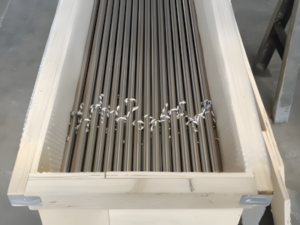

Packing

Packing

To ensure that our 303 stainless steel round bars and flat bars remain intact during transportation, we provide professional packaging solutions to ensure that each product is delivered to you safely and intact.

- Professional packaging: We provide sturdy wooden boxes or steel strapping for 303 stainless steel round bars and flat bars to prevent damage or deformation during transportation.

- Protective measures: Each stainless steel bar is individually packaged with moisture-proof and corrosion-resistant materials to ensure that the product remains in good condition during transportation and storage.

- Label identification: Each package is affixed with a clear product label indicating the material, specification and batch number for easy identification and quick search.

- Global transportation: No matter where you are in the world, we can provide safe and efficient logistics solutions to deliver your orders on time.

Why Choose Us

Why Choose Us

We are committed to providing customers with the best quality materials and services to meet different production needs.

- High-quality materials: Our 303 stainless steel round bars and flat bars are made of high-standard stainless steel raw materials to ensure that the products have excellent corrosion resistance and long service life in various environments.

- Excellent processability: The addition of sulfur elements makes our 303 stainless steel round bars and flat bars have excellent processability, suitable for a variety of processing processes such as turning, milling and drilling, and improve your production efficiency.

- Strict quality control: Each batch of products undergoes rigorous testing to ensure that the dimensional accuracy and mechanical properties meet the highest industry standards, providing you with reliable and stable product quality.

- Customized service: We provide 303 stainless steel round bars and flat bars in a variety of sizes and specifications, and support on-demand customization to meet your special needs.

- Fast delivery: We have sufficient inventory and efficient supply chain management to ensure that your orders can be shipped quickly and ensure that the project is completed on time.