DX54D+Z Galvanized Steel Coil

DX54D+Z Galvanized Steel Coil

SteelPRO Group is DX54D galvanized steel coils supplier that meet global standards such as EN and ASTM, and has a variety of other grades and types of galvanized steel, such as dx51d plates, roof panels, and galvanized steel pipes. Our DX54D galvanized steel coils have excellent corrosion resistance and deep drawing properties, suitable for automotive manufacturing, home appliances, construction and other scenarios. We provide a variety of surface treatments such as passivation and oiling, as well as light and heavy galvanizing, to meet customers’ multi-level application needs.

- Standard: EN 10346, ASTM A653, JIS G3302, ISO 3575, GB/T 2518

- Grades: DX54D, DX54D+Z, ASTM A653 CS Type B, SGCD4

- Technology: Hot Dip Galvanizing, cold rolling

- Certification: ISO 9001, CE

DX54D+Z Galvanized Steel Coil

DX54D+Z Galvanized Steel Coil

Product Specifications

Product Specifications

| Product Name | DX54D+Z Hot Dip Galvanized Steel Coil |

| Thickness | 0.12mm – 6.0mm, Customized |

| Width | 600mm – 1500mm, Customized

Regular: 1000mm, 1219mm, 1250mm, 1500mm |

| Length | 1000mm – 6000mm, Customized |

| Zinc Coating | 20-400g/m², g30, g40, g60, g90, etc. |

| Coil ID | 508mm / 610mm |

| Surface Treatment | Anti-finger print / Skin pass / Oiled / Dry / Chromated / Embossed / Lamination |

| Spangle | Zero Spangle / Mini Spangle / Regular Spangle / Large Spangle |

| Test | Zinc Coating Thickness Test, Bend, Cross-hatch, Salt Spray Test, Tensile Test, etc. |

| Edge | Mill edge, Cut edge |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing | By actual weight |

| Delivery Time | 7-15 days |

| Payment | T/T, L/C, Credit Card |

| Port | Shanghai, Qingdao or according to your requirement |

| Packaging Details | In bundles, in bulk, customized packing |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Aluminum (Al) | Nitrogen (N) | Titanium (Ti) |

|---|---|---|---|---|---|---|---|

| Maximum Content (%) | 0.08 | 0.4 | 0.03 | 0.025 | 0.015 – 0.070 | 0.012 | 0.3 |

Mechanical properties

Mechanical properties

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 270 – 370 |

| Yield Strength (MPa) | ≤ 220 |

| Elongation (%) | ≥ 38 |

| Vickers Hardness (HV) | 90 – 120 |

| Brinell Hardness (HB) | 90 – 110 |

| Rockwell Hardness (HRB) | 50 – 70 |

| Elastic Modulus (GPa) | ~210 |

Industries & Applications

Industries & Applications

- Automobile manufacturing: Applicable to body parts, doors, roofs and other parts. Due to its excellent ductility and deep drawing performance, it can meet the needs of complex stamping.

- Home appliance manufacturing: Widely used in the outer shell and internal structure of home appliances such as refrigerators, washing machines, air conditioners, etc., providing durability and good corrosion resistance.

- Building decoration: Used in decorative materials such as building wall panels, roof panels, curtain walls, etc., with both decorative and anti-corrosion properties, suitable for indoor and outdoor applications.

- Light structural components: Applicable to light structures such as ceiling keels and partitions, providing stable structural support for buildings.

- Pipeline and ventilation system: Applicable to water, gas pipelines and ventilation pipeline systems in low-corrosion environments, providing corrosion resistance and extending service life.

- Solar energy and power facilities: Suitable for outdoor facilities such as solar brackets and power equipment, with high corrosion resistance, suitable for long-term exposure to outdoor environments.

Other Infomation

Other Infomation

Here are a few of the surface finishes we offer to help you choose the option that’s best for your project:

- Anti-Fingerprint: This treatment adds a thin layer that repels fingerprints and stains, keeping the surface clean and beautiful. It’s ideal for appliances and decorative uses where appearance is important.

- Buffing: This treatment creates a smoother, flatter surface, enhancing shine and stability during further processing. It’s ideal for applications that require additional forming or stamping.

- Oiled: We apply a protective layer of oil to prevent oxidation and rust, ideal for steel that may be stored, shipped, or exposed for long periods of time.

- Dry: This is untreated steel that has not been oiled or passivated. It’s ideal for projects that require immediate processing and don’t require high corrosion resistance.

- Chromated (Passivated): Chromated steel has a protective chemical layer that increases corrosion resistance, ideal for wet or slightly corrosive environments.

- Embossed: Embossing creates a textured surface that adds decorative appeal and reduces glare. It’s often used for exterior cladding or decorative panels.

- Laminated: Laminating provides an additional protective film against corrosion and scratches. This is ideal for high wear or corrosive environments where durability is critical.

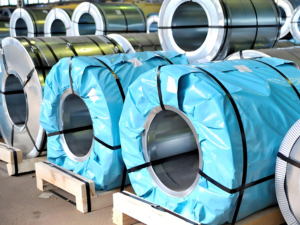

Our Inventory

Our Inventory

SteelPRO Group has advanced production equipment and efficient production lines, and has established long-term cooperative relationships with many well-known companies to ensure stable production capacity and excellent product quality. Our production base has a high annual output and can quickly respond to large-volume order needs, providing strong support for customers and meeting rapidly changing market needs. We are committed to providing every customer with reliable steel solutions through innovation and quality management.

Main products: steel pipes, steel plates, steel coils, steel bars, steel strips, stainless steel series, carbon steel series, high-strength steel series, nuclear grade steel, galvanized steel, steel for wind and solar energy, etc.

Packing

Packing

- Wrap with waterproof film or moisture-proof paper to prevent moisture penetration, suitable for sea transportation or high humidity environment.

- Anti-rust oil and anti-rust paper are applied on the outside to extend the anti-corrosion time, suitable for long-distance transportation or long-term storage.

- Metal side guards are installed to prevent damage during handling and stacking, suitable for multi-roll stacking transportation.

- Plastic film packaging isolates air contact and keeps clean, suitable for transportation in special environments.

- Wooden pallets and steel belts fix steel coils to ensure stable transportation and easy loading and unloading.

- Each roll is labeled with specifications, weight, etc. for easy identification and logistics management.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

What international quality standards does your steel meet?

Our steel meets a number of international standards, including EN, ASTM, JIS, etc., to ensure that it meets the needs of industries in different regions. Our products undergo strict quality control to ensure that they meet the high standards of the global market.

How to choose the right type of steel for your project?

When choosing the type of steel, you need to consider the specific needs of the project, such as forming requirements, strength, corrosion resistance, etc. Our professional team can provide guidance based on your project to help you find the most suitable steel.

How is the corrosion resistance of steel?

Our steel undergoes a variety of anti-corrosion treatments, especially galvanizing, which can maintain long-term durability in humid or corrosive environments, effectively reducing maintenance costs and extending service life.

What are the steel surface treatment options?

We provide a variety of surface treatments, including galvanizing, oiling, passivation, etc., to enhance the anti-oxidation and anti-corrosion properties of steel. You can choose the appropriate surface treatment solution according to the use environment.

What are the protection measures for steel during transportation?

We adopt professional packaging solutions, including moisture-proof, rust-proof and anti-damage measures, to ensure that the steel remains intact during transportation. Strict packaging and transportation processes ensure that the products are delivered safely to customers.

How long is the service life of steel?

The service life of steel depends on the environment and maintenance. Generally, under normal conditions, our galvanized steel can maintain a service life of more than 20 years, and can be extended with proper maintenance.

CONTACT

Certificates and Cooperation

Certificates and Cooperation