HIGH TEMPERATURE ALLOY

Extreme Heat. Extreme Performance. High Temp Alloys Built to Endure.

Introduction to High Temperature Alloy

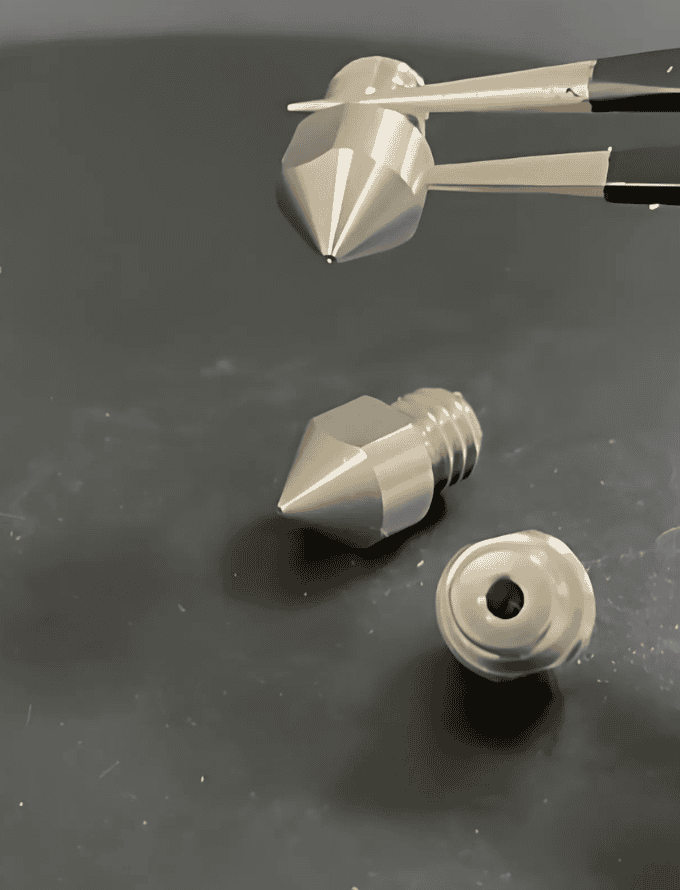

High-temperature alloys, also known as superalloys, are crafted for exceptional strength and stability in extreme heat. Typically based on nickel, cobalt, or iron, they offer impressive strength that typically ranges between 500 – 1,500 MPa (72.5 – 217.5 ksi) and resist heat, oxidation, and corrosion, even at temperatures up to 1,200°C.

These alloys are enhanced through advanced techniques like precipitation hardening (particularly nickel-based ones) and powder metallurgy, ensuring durability and performance under stress. With added elements like chromium and aluminum for stability, they are essential in industries like aerospace and power generation, where reliability in extreme environments is key.

Benefits of High Temp Alloy

Our selection of high-temperature alloys are designed to deliver exceptional performance in the most demanding environments. The benefits of these advanced materials include:

- Stay strong at high temperatures

- Resist oxidation and scaling

- Durable and long-lasting

- Less maintenance needed

- Easy to shape and work with

- Can be coated for extra protection in tough environments

Grades of High Temperature Alloy

Carbon steel and HSLA steel are the main types specifically classified as shipbuilding steel. Other types, like nickel steel, stainless steel, duplex stainless steel, maraging steel, weathering steel, and tool steel, are also used in shipbuilding but are not exclusively used for it.

- Nickel-Based Alloys: Inconel 625 (NA21), Inconel 718 (NA51), Hastelloy X (N06002), Nimonic 90 (N07090), Haynes 230 (N06230), Waspaloy (N07001), etc.

- Cobalt-Based Alloys: Haynes 188 (R30188), Haynes 25 (L-605) (R30605), Stellite 6B (UNS R30016), MAR-M 509 (N15500), Ultimet (R31233), etc.

- Iron-Based Alloys: Incoloy 800 (N08800), Incoloy 825 (N08825), A286 (S66286), Hastelloy S (N06635), RA330 (N08330), etc.

Industries & Applications

Some common industries and applications include:

Aerospace & Defense

Jet engines, turbine blades, afterburners, combustors, heat shields, etc.

Power Generation

Gas turbines, steam turbines, nuclear reactor components, boiler tubes, etc.

Automotive & Motorsport

Turbochargers, exhaust manifolds, intake and exhaust valves, catalytic converters, etc.

Chemical Processing

Furnace tubes, heat exchangers, chemical reactors, reformer tubes, pressure vessels, etc.

Oil & Gas

Downhole tubing, wellhead components, gas turbines, refinery heat exchangers, catalytic cracking units, etc.

Industrial Manufacturing

Furnace linings, tooling for forging and casting, extrusion dies, heat-treating equipment, etc

Marine Engineering

Exhaust valves, propulsion system components, gas turbines, heat exchangers, etc

Medical Device Manufacturing

Sterilization equipment, high-temperature surgical tools, implants subject to high-temperature sterilization, etc

Dimensions & Properties

| Inconel 718 | Haynes 188 | A286 Alloy | |

|---|---|---|---|

| Tensile Strength | 1370 MPa (198.7 ksi) | 870 MPa (126.2 ksi) | 1000 MPa (145.0 ksi) |

| Yield Strength | 1035 MPa (150.2 ksi) | 410 MPa (59.5 ksi) | 690 MPa (100.1 ksi) |

| Material Standard | ASTM B637 | ASTM F1055 | ASTM A453 |

| Vickers Hardness | 360 HV | 260 HV | 248 HV |

High Strength Steels When & Where You Need It

At SteelPRO Group, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.