2205 Stainless Steel Pipe, Plate, Sheet & Bar

2205 Stainless Steel Pipe, Plate, Sheet & Bar

SteelPRO Group is a reliable 2205 stainless steel pipe, plate, sheet and bar supplier and manufacturer from China. We provide customizable processing methods for various 2205 stainless steel products, including cutting, welding, polishing, heat treatment, etc.

Our products: 2205 stainless steel hot rolled plate, 2205 cold rolled sheet, 1.4462 seamless pipe & tube, 2205 welded pipe & tube, 318S13 polished sheet, 2205 brushed plate, S32205 round bar, 2205 flat bar, 2205 square bar, 2205 hollow bar.

| Standard | ASTM A240, ASTM A276, ASTM A479, ASTM A790, ASTM A928 |

|---|---|

| Grade | 1.4462, 318S13, S32205, X2CrNiMoN22-5-3 |

| Length | 2 m-12 m (6.6-40 ft), Customized |

| OD | Customized, Pipe: 6 mm-600 mm (0.24-24 in) |

| WT | Customized, Pipe: 0.5 mm-50 mm (0.02-2 in) |

| Thickness | Customized, Plate: 5 mm-150 mm (0.2-6 in), Sheet: 0.5 mm-5 mm (0.02-0.2 in) |

| Full Width | Customized, Plate: 1000 mm-3000 mm (39.37-118.11 in), Sheet: 1000 mm-2000 mm (39.37-78.74 in) |

| Diameter | Bar: 6 mm-600 mm (0.24-24 in), Customized |

| Shape | Customized, etc., Flat, Oval, Pipe & Bar: Round, Rectangular, Square |

| Surface Finish | BA, Black, Customized, No. 2D, No.1, No.4, Pickled, Polished |

| Form | 2205 angle bar, 2205 hot rolled sheet & plate, 2205 polished plate, 2205 round/flat/square/hexagonal bar, 2205 seamless pipe, Coil, cold rolled sheet & plate, Customized, ERW Pipe, Strip, T-bar, Tube, U-Bend Pipe, Welded Pipe |

2205 Stainless Steel Pipe, Plate, Sheet & Bar

2205 Stainless Steel Pipe, Plate, Sheet & Bar

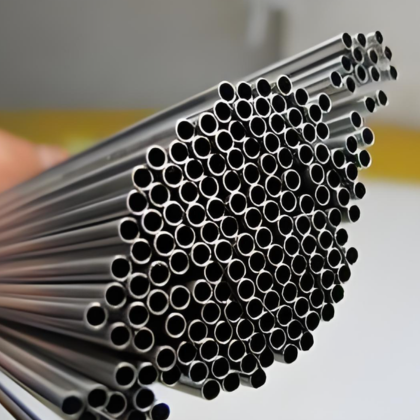

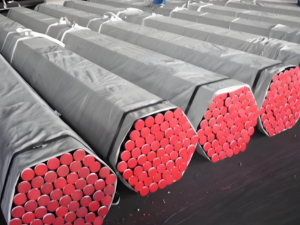

- 2205 Pipe is a duplex steel product that combines austenite and ferrite phases, offering high corrosion resistance, excellent strength, and good weldability. It is particularly resistant to stress corrosion cracking, making it ideal for use in oil and gas pipelines, marine applications, heat exchangers, and chemical processing plants.

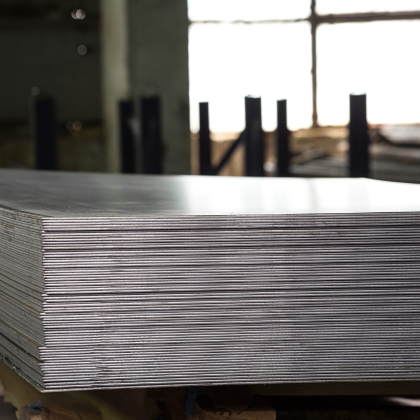

- 2205 Plate is a duplex flat product known for its strong resistance to pitting and crevice corrosion, high yield strength, and excellent fatigue resistance. It is commonly used in pressure vessels, chemical storage tanks, offshore structures, and various marine industry components due to its good thermal conductivity.

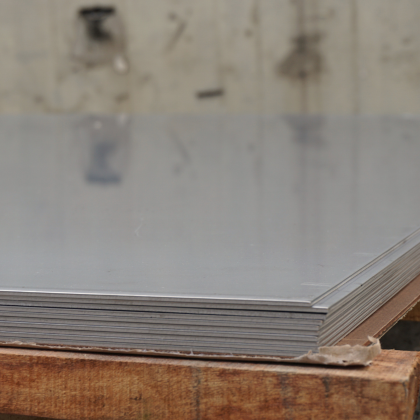

- 2205 Sheet features a high strength-to-weight ratio, strong oxidation resistance, and ease of fabrication. It is commonly used in building cladding, heat exchangers, desalination plants, and food processing equipment due to its ability to maintain structural integrity and resist corrosion in demanding conditions.

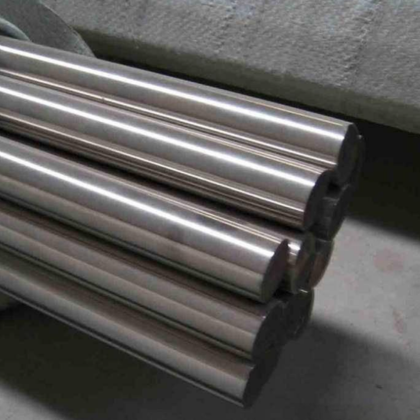

- 2205 Bar is a solid duplex steel product that offers high tensile strength, excellent wear resistance, and outstanding machinability. It is widely used in applications such as shafts, pumps, valve components, fasteners, and marine equipment.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Australia, Canada, Korea, United Kingdom, Russian Federation, India, Brazil, Germany, Netherlands, Taiwan, New Zealand, Italy, Spain, Philippines, Chile, France, Indonesia, Malaysia, Norway, Pakistan, Poland, Portugal, Saudi Arabia, Singapore, South Africa, Sweden, Turkey, United Arab Emirates, etc.

|

Chemical Compositions

Chemical Compositions

| Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤0.03 | ≤2.00 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.14-0.20 |

Mechanical Properties

Mechanical Properties

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515-720 MPa | 74,700-104,400 psi |

| Yield Strength | 205 MPa | 29,700 psi |

| Brinell Hardness (HB) | 150-220 HB | 150-220 HB |

| Rockwell Hardness (HRC) | 20-30 HRC | 20-30 HRC |

| Vickers Hardness (HV) | 160-220 HV | 160-220 HV |

| Elongation | 40-60% | 40-60% |

| Elastic Modulus | 193-200 GPa | 28,000-29,000 ksi |

Heat Treatment

Heat Treatment

- Annealing (Solution Annealing)

- Applies to: Pipes, Plates, Sheets, Bars

- Process: Heat to 1020-1100°C (1868-2012°F) and cool rapidly, usually in water or air.

- Quenching

- Applies to: Pipes, Plates, Sheets, Bars (as part of the solution annealing process)

- Process: Solution anneal followed by rapid cooling by quenching in water or air.

- Stress Relief

- Not usually recommended for 2205 Duplex

- Aging, Normalizing, Tempering, Hardening

- Not applicable to 2205 Duplex

Characteristic

Characteristic

- 2205 pipe offers high strength and excellent corrosion resistance. Its good weldability allows for seamless connections without the risk of cracking or deformation. In addition, it has excellent resistance to stress corrosion cracking in chloride and sulfide environments.

- 2205 plate offers exceptional durability, with a yield strength nearly twice that of standard austenitic stainless steels. It has excellent resistance to localized corrosion, especially in saltwater or acidic environments. It maintains good toughness at low temperatures, and its high fatigue strength ensures long-lasting durability in cyclically stressed environments such as pressure vessels.

- 2205 sheet is easy to form and fabricate, making it suitable for use in complex shapes while maintaining high strength, durability and corrosion resistance. With a higher strength-to-weight ratio than 304 or 316 stainless steel, it is a cost-effective option that allows for thinner sections without compromising performance. The plate also has strong oxidation resistance at elevated temperatures.

- 2205 bar has excellent wear resistance and high tensile strength for heavy-duty applications such as shafts, pumps and fasteners. It has good machinability and also performs well in extreme temperatures and corrosive environments.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

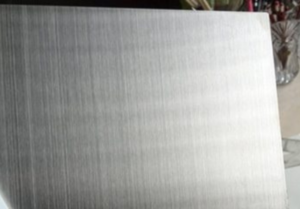

Surface Finish

Surface Finish

2B Surface

2D Surface

BA Surface

6K Surface

8K Surface

HL Surface

NO.1 Surface

NO.4 Surface

Embossed Surface

Packing

Packing

At SteelPRO Group, each of our product types is packaged using specific materials and methods to guarantee they arrive in perfect condition.

- Stainless Steel Pipes

Our pipes are wrapped in plastic film to protect against moisture and corrosion, then strapped together with metal bands. For larger orders, the bundles are placed in wooden pallets or wooden boxes to prevent movement during shipping. We also offer custom crate packaging for sensitive shipments or overseas deliveries to further ensure the safety of the pipes. - Stainless Steel Plates and Sheets

The plate and sheets are stacked with protective wooden or steel frames to avoid surface damage. Each plate/sheet is separated by rust-proof paper or plastic sheeting to minimize friction and scratches. They are then securely strapped to pallets and shrink-wrapped to ensure stability and protection from the environment during shipping. - Stainless Steel Bars

The bars are wrapped in plastic film to protect against moisture and rust. Smaller bars are strapped into bundles with durable bands, while larger bars are placed individually in wooden boxes. Depending on the bar size and shipping destination, we may also use steel bar packaging for added stability and protection.

Why Choose Us

Why Choose Us

SteelPRO Group is your reliable partner for quality stainless steel. We focus on excellence and customer satisfaction.

- Uncompromising Quality: We source from top steel mills and ensure that every batch meets strict industry standards through rigorous testing.

- Diverse Product Range: Our stock includes plates, tubes, bars, coils and strips in standard or custom sizes to suit every industry.

- Tailor-made Solutions: We offer personalized advice and products tailored to your project needs.

- Reliable and Timely Delivery: With a strong supply chain, we guarantee on-time delivery.

- Excellent Customer Service: Our team is always available to provide technical, logistical and after-sales support by phone or email.