2507 Stainless Steel Pipe, Bar & Coil

2507 Stainless Steel Pipe, Bar & Coil

SteelPRO Group is a plate supplier, strip manufacturer with coil mill, round bar mill. We provide customized steel solutions, precision cutting, timely delivery, quality assurance and technical support to our customers.

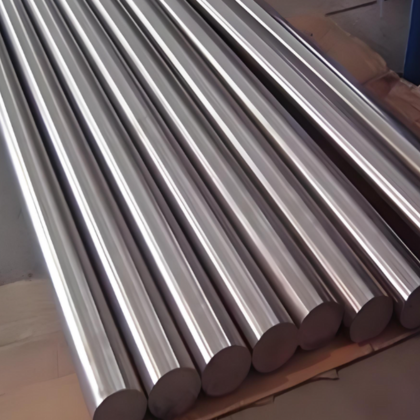

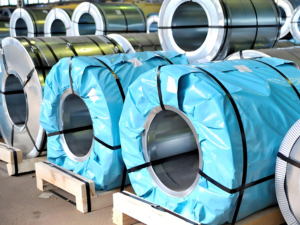

Our products: 1.4410 Pipe, S32760 Bar, S32750 coil, 2507 Seamless Pipe, 2507 Welded Pipe, 2507 Round Bar, Hexagonal Bar, 2507 Cold Rolled Coil, Hot Rolled Coil, Precision Coil, 2507 Flat Bar.

| Standard | ASTM A240, ASTM A276, ASTM A479, ASTM A789, ASTM A790 |

|---|---|

| Grade | 1.4410, S32750, S32760, X2CrNiMoN25-7-4 |

| Length | Bar: 3 m-6 m (10-20 ft), Customized, Pipe: 6 m-12 m (20-40 ft) |

| Diameter | Bar: 10 mm-400 mm (0.39-15.75 in), Customized, Pipe (OD): 6 mm-600 mm (0.24-24 in) |

| Full Width | Coil: 1000 mm-1500 mm (39.37-59.06 in), Customized |

| Thickness | Coil: 0.3 mm-3 mm (0.012-0.12 in), Customized, Pipe (WT): 1 mm-50 mm (0.04-2 in) |

| Shape | Customized, Pipe & Bar: Round/Square/Rectangular/Hexagonal/Flat |

| Surface Finish | 2B, BA, Brushing, etc., Mirror Finish, No.4, Pickling, Polishing, Turned |

| Form | 2507 cold rolled coil, 2507 round bar, 2507 seamless pipe, Annealed coil, Bar rod, etc., Foil, heat exchanger pipe, hot rolled bar, Plate, PolishED Bar, Rod, Round Pipe, Sheet, Strip, Strip Coil, Tube, Welded Pipe |

2507 Stainless Steel Pipe, Bar & Coil

2507 Stainless Steel Pipe, Bar & Coil

- 2507 pipe is used in demanding applications such as offshore oil rigs, chemical processing plants, and desalination systems.

- 2507 rod is commonly used to produce shafts, fasteners, and components for industries such as offshore engineering, chemical processing, and oil and gas exploration.

- 2507 coil is commonly used to manufacture heat exchangers, pressure vessels, and structural components for marine, petrochemical, and chemical processing applications.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, United Kingdom, Australia, Russian Federation, Italy, Brazil, New Zealand, Canada, Indonesia, Netherlands, United Arab Emirates, Denmark, Japan, Korea, Norway, Poland, Saudi Arabia, Singapore, Spain, Taiwan, Thailand, Turkey, Vietnam, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 24.0 – 26.0 | 6.0 – 8.0 | 3.0 – 5.0 | 0.24 – 0.32 | ≤ 0.03 | ≤ 1.20 | ≤ 0.80 | ≤ 0.035 | ≤ 0.015 |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 800 – 1000 MPa | 116 – 145 ksi |

| Yield Strength | ≥ 550 MPa | ≥ 80 ksi |

| Vickers Hardness | 270 – 310 HV | — |

| Brinell Hardness | 260 – 300 HB | — |

| Rockwell Hardness | 32 HRC | — |

| Elongation | 15% | 15% |

| Elastic Modulus | 200 GPa | 29.0 × 10^6 psi |

Heat Treatment

Heat Treatment

- Solution Annealing

- Applicable to tubes, bars, coils

- Process: 2507 stainless steel is heated to a temperature range of 1020°C to 1100°C, followed by rapid cooling (usually water quenching or air cooling).

- Stress Relieving Annealing

- Applicable to tubes and bars

- Process: Annealing time is generally 1 to 2 hours, carried out at low temperatures of 250°C to 500°C, followed by slow cooling.

- Annealing

- Applicable to tubes, bars, coils

- Process: Heating and holding at 1020°C to 1100°C for a certain period of time, followed by slow cooling.

- Precipitation Hardening, Nitriding, Quenching and Tempering are not applicable to 2507 Super Duplex Stainless Steel.

Characteristic

Characteristic

- 2507 pipe: has ultra-high strength and excellent pressure resistance, and has outstanding resistance to pitting and crevice corrosion. The pipe can also maintain stable mechanical properties under high temperature and high pressure conditions, and is suitable for use in harsh environments.

- 2507 bar: has extremely high tensile strength and corrosion resistance, especially in acidic, alkaline and high-chlorine environments. It also has excellent fatigue resistance, suitable for manufacturing high-strength mechanical parts and fasteners, and has strong durability.

- 2507 coil: not only has high strength and excellent corrosion resistance, but also has good processing performance, and can be formed by cutting, bending, welding and other processes. Its excellent heat resistance and corrosion resistance make it suitable for a variety of complex environments.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

Packing

Packing

At SteelPRO, we prioritize the safe delivery of your products. Each 2507 stainless steel item is carefully packaged to ensure it arrives in perfect condition.

- Heavy-Duty Protection: Corrosion-resistant materials safeguard your products during transit.

- Customized Packaging: Tailored to fit the specific dimensions and needs of pipes, bars, and coils.

- Shock-Resistant Materials: Extra cushioning prevents damage during shipping.

- Weatherproof Sealing: Protection against harsh weather conditions during shipping, especially for international deliveries.

- Eco-Friendly Packaging Options: Sustainable packaging solutions without compromising on quality.

We combine precision, reliability, and sustainability to deliver the best products and service to our customers.

Why Choose Us

Why Choose Us

At SteelPRO, we are committed to delivering the highest quality 2507 stainless steel products to meet your toughest challenges. Our extensive experience in super duplex stainless steel and dedication to customer satisfaction sets us apart.

- Expertise in Super Duplex Stainless Steel: We ensure that our 2507 stainless steel products meet the highest standards for strength and corrosion resistance.

- Customized Solutions: Tailored dimensions and finishes to meet your exact specifications.

- Strict Quality Control: Rigorous testing ensures top performance and durability for every product.

- Fast and Reliable Delivery: Efficient logistics ensure your orders arrive on time, minimizing disruptions.

- Sustainable Practices: We employ eco-friendly manufacturing processes to minimize waste and energy consumption.