SA508 | A508 | Low Alloy Steel | Pressure Vessel Steel

SA508 | A508 | Low Alloy Steel | Pressure Vessel Steel

SA508 is a low-alloy steel used mainly in the fabrication of pressure vessels and nuclear reactors. It conforms to the ASTM standard. The “SA” indicates it meets ASME standards and is safe and reliable in high-pressure environments. While “508” is the specific material grade. Equivalent grades include A508 (ASTM). This steel offers excellent toughness, high strength, and good weldability. It is widely used in critical applications like nuclear reactor pressure vessels due to its ability to withstand high pressure and temperature.

Description

What Is SA508?

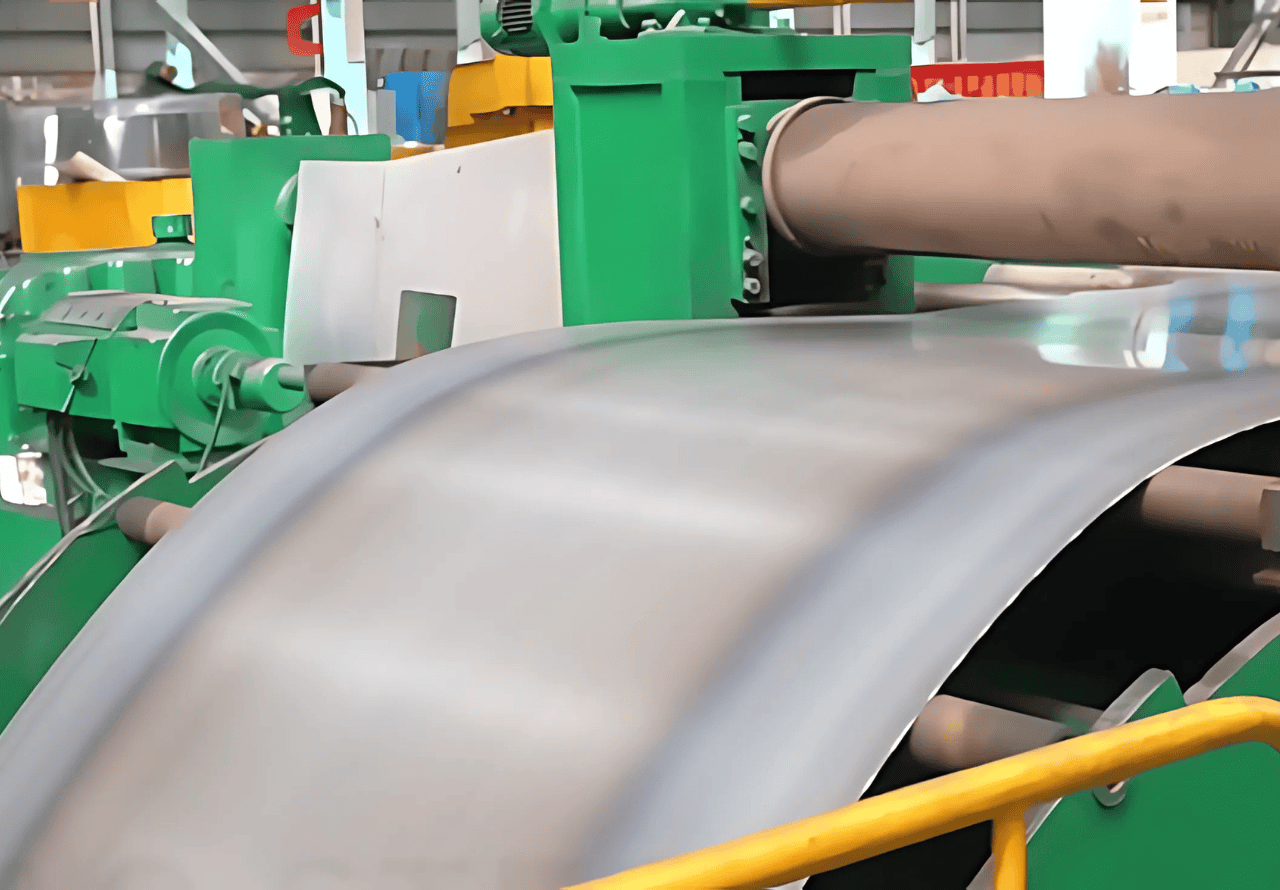

SA508 is a type of steel primarily composed of approximately 98% iron, with 0.15-0.30% carbon, along with other alloying elements like manganese, silicon, and molybdenum. It is usually manufactured in the form of solid, high-strength plates. This steel is categorized as a pressure vessel steel, known for its excellent toughness and strength at both low and high temperatures. SA508 steel is predominantly used in the fabrication of pressure vessels and reactor components in nuclear power plants. The material is typically produced through a hot rolling process, ensuring uniformity and enhanced mechanical properties. SA508 can be classified into several grades, such as Gr.1, Gr.2, and Gr.3, each tailored for specific pressure and temperature requirements.Characteristics of SA508 Steel

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.25 |

| Manganese (Mn) | 1.20 |

| Silicon (Si) | 0.60 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Nickel (Ni) | 0.25 |

| Chromium (Cr) | 0.25 |

| Molybdenum (Mo) | 0.08 |

| Copper (Cu) | 0.35 |

| Vanadium (V) | 0.05 |

| Boron (B) | ≤ 0.003 |

| Iron (Fe) | Balance |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm³ | 0.283 lb/in³ |

| Melting Point | 1450-1520 °C | 2642-2768 °F |

| Boiling Point | – | – |

| Thermal Conductivity | 42.2 W/m·K | 24.4 BTU/h·ft·°F |

| Electrical Conductivity | 2.5 % IACS | 2.5 % IACS |

| Specific Heat Capacity | 0.46 J/g·K | 0.11 BTU/lb·°F |

| Thermal Expansion Coefficient | 11.1 x 10⁻⁶ /K (20°C to 100°C) | 6.17 x 10⁻⁶ /°F (68°F to 212°F) |

| Electrical Resistivity | 0.65 µΩ·m | 0.00065 Ω·mm²/m |

Mechanical Properties

AC (Air Cooled) Sate

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 620 – 830 MPa | 90 – 120 ksi |

| Yield Strength | 345 – 450 MPa | 50 – 65 ksi |

| Brinell Hardness | 179 – 235 HB | 179 – 235 HB |

| Rockwell Hardness | 110 – 138 HRB | 110 – 138 HRB |

| Vickers Hardness | 166 – 218 HV | 166 – 218 HV |

| Elongation | 18 – 22% | 18 – 22% |

| Elastic Modulus | 200 GPa | 29 msi |

QT (Quenched & Tempered) State

| Property | Metric (MPa, %) or (GPa) | Imperial (ksi, %) or (GPa) |

|---|---|---|

| Tensile Strength | 586 – 827 MPa | 85 – 120 ksi |

| Yield Strength | 379 – 517 MPa | 55 – 75 ksi |

| Elongation | 16 – 20% | 16 – 20% |

| Reduction of Area | 60 – 75% | 60 – 75% |

| Impact Absorption Energy | 100 – 150 J | 73.8 – 110.6 ft-lb |

| Elastic Modulus | 200 GPa | 29 msi |

Industries & Applications

| Industry | Application |

|---|---|

| Nuclear Power | Reactor Pressure Vessels, Steam Generators, Pressurizers, Reactor Internals |

| Oil & Gas | Pressure Vessels, Heat Exchangers, Piping Systems, Storage Tanks |

| Chemical Processing | Reactors, Distillation Columns, Heat Exchangers, Storage Tanks |

| Power Generation | Turbine Casings, Boiler Drums, Heat Exchangers, Pressure Vessels |

| Marine | Submarine Hulls, Ship Structures, Pressure Vessels, Piping Systems |

| Aerospace | Engine Components, Landing Gear, Structural Components, Pressure Vessels |

| Defense | Armor Plates, Gun Barrels, Vehicle Structures, Pressure Vessels |

| Construction | Structural Beams, Columns, Heavy Machinery Components, Pressure Vessels |

| Automotive | Engine Blocks, Transmission Components, Suspension Components, Pressure Vessels |

Machining

Heat Treatment

- Forging Temperature: Heat uniformly to 1200°C to 1280°C (2192°F to 2336°F); avoid prolonged soaking.

- Cooling after Forging: Cool in air or furnace to prevent unwanted microstructures.

- Normalizing: Heat to 900°C to 950°C (1652°F to 1742°F), hold at temperature, and air cool to room temperature.

- Quenching: Reheat to 900°C to 950°C (1652°F to 1742°F), then quench in water or oil.

- Tempering: Temper at 600°C to 700°C (1112°F to 1292°F), hold at temperature, and air cool.

- Stress Relieving (if required): Heat to 600°C to 650°C (1112°F to 1202°F), hold, and air cool.

- Final Inspection and Testing: Conduct hardness, tensile, impact testing, and ultrasonic examination as needed.

Surface Finish

- Polishing: Using abrasive materials to achieve a glossy or mirror-like finish, smoothing the surface.

- Grinding: Removing material from the surface using a grinding wheel or abrasive belt to achieve a specified finish.

- Sandblasting: Propelling abrasive particles at high velocity against the surface to clean or etch the material.

- Pickling: Using acid solutions to remove oxides and scale from the surface.

- Passivation: Treating the surface with an acid solution to remove contaminants and enhance corrosion resistance.

- Brushing: Creating a unidirectional satin finish using a wire brush or abrasive pad.

- Electropolishing: Using an electrochemical process to remove material from the surface and improve its smoothness and brightness.

- Coating: Applying a protective or decorative layer to the surface, such as paint, powder coating, or plating.

*Customization is available upon request.

Disclaimer

The provided heat treatment and surface treatment processes are general guidelines. Actual conditions may vary depending on specific applications and requirements. It is recommended to consult with a professional metallurgist or material scientist to tailor the processes to your particular needs. The information herein is not a substitute for professional advice and should not be relied upon as such.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...