Contents

309 Stainless Steel: Composition, Properties, Applications, Forms, Comparison, and More

- John

We will take an in-depth look at 309 stainless steel, including its chemical composition, mechanical and physical properties, various forms, applications, and comparisons to other stainless steel grades. We will at the same time describe the advantages and disadvantages of using this material and its processing methods.

What is 309 Stainless Steel?

309 stainless steel is an austenitic stainless steel in the 300 series. Thanks to the high chromium and nickel content, they have outstanding oxidation and corrosion resistance despite extreme environments. Compared to other stainless steel grades, 309 can maintain its structural integrity under continuous heat exposure and is often used in high temperature environments.

309 stainless steel equivalent grades

Different countries and industries use various standards to classify stainless steel. Here are the equivalent grades of 309 stainless steel:

- UNS: S30900

- EN: X15CrNiSi20-12

- DIN: 1.4828

- JIS: SUH 309

- GB: 1Cr20Ni14Si2

309 stainless steel standard

ASTM A240, ASTM A167, ASTM A276, ASTM A312, ASTM A580, ASTM A479, ASTM A473, ASTM A314

Chemical Composition of 309 Stainless Steel

The chemical composition of 309 stainless steel is crucial to its ability to resist heat and corrosion. It contains a higher percentage of chromium and nickel than many other grades, resulting in beneficial properties.

| Element | Composition Range |

| Carbon (C) | ≤ 0.20% |

| Manganese (Mn) | ≤ 2.00% |

| Silicon (Si) | ≤ 1.00% |

| Chromium (Cr) | 22.0% – 24.0% |

| Nickel (Ni) | 12.0% – 15.0% |

| Sulfur (S) | ≤ 0.030% |

| Phosphorus (P) | ≤ 0.045% |

309 Stainless Steel Properties

Key Features

309 stainless steel offers several key benefits:

Heat Resistance: It can withstand temperatures up to 1900°F (1038°C) in continuous service and 2000°F (1093°C) in intermittent service, making it highly useful in applications that involve prolonged exposure to heat.

Corrosion Resistance: Featuring a substantial chromium content, it offers remarkable resilience against corrosion, particularly under conditions of high temperatures.

Strength: Retaining its mechanical integrity even in elevated temperature settings, it is ideally suited for applications in industrial furnaces, boiler interiors, and other high-temperature machinery.

Physical Properties

309 stainless steel has the following physical properties:

| Property | Metric | Imperial |

| Density | 8.00 g/cm³ | 0.289 lb/in³ |

| Melting Point | 1400–1455°C | 2550–2651°F |

| Thermal Conductivity | 15.6 W/m-K | 108 BTU-in/hr-ft²-°F |

| Coefficient of Thermal Expansion | 14.9 µm/m°C | 8.28 µin/in°F |

| Specific Heat | 0.12 J/g°C | 0.12 BTU/lb°F |

| Electrical Resistivity | 468 μΩ-cm | 468 μΩ-cm |

Mechanical Properties

The mechanical properties of 309 stainless steel are what make it particularly useful in high-stress, high-heat applications:

| Property | Metric | Imperial |

| Tensile Strength (Ultimate) | 620 MPa | 89900 psi |

| Yield Strength (0.2% offset) | 290 MPa | 42100 psi |

| Elongation at Break | 50% | 50% |

| Hardness (Rockwell B) | 85 | 85 |

| Modulus of Elasticity | 200 GPa | 29000 ksi |

| Shear Modulus | 77 GPa | 11200 ksi |

Forms of 309 Stainless Steel

309 stainless steel is available in various forms, each suited for different industrial uses. Here is an overview of the available forms and their typical applications:

- Rod, Round Bar, Bar Stock: Used in construction, industrial machinery, and high-temperature fasteners.

- Sheet, Plate: Ideal for heat exchangers, furnaces, and high-temperature containers.

- Tool Wrap, Foil: Used in the heat treatment of smaller parts.

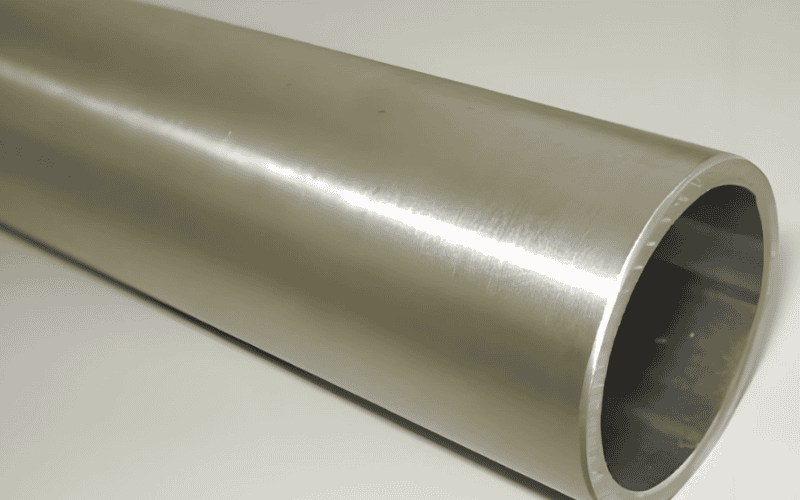

- Pipe, Tube: Often used in high-temperature fluid transport systems and piping for petrochemical plants.

- Welding Wire, MIG Wire, TIG Wire: Used for welding 309 stainless steel and other similar alloys.

- Washers, Fasteners, Screws, Bolts: Utilized in high-temperature, high-stress environments where corrosion resistance is essential.

- Mesh, Angle: Found in construction, filtration systems, and mechanical applications.

Application of 309 Stainless Steel

309 stainless steel is widely applied in environments that experience high temperatures and corrosive conditions. Common applications include:

Furnace Components: Such as firebox sheets and furnace linings, where the material is subjected to continuous high heat.

Heat Exchangers: The material’s resistance to corrosion and oxidation makes it a prime choice for heat exchangers.

Boiler Baffles: Used in industrial boilers where high strength and heat resistance are required.

Oven Linings and Components: For commercial and industrial ovens, 309 stainless steel ensures durability under high temperatures.

Kiln Linings: Used in ceramic, glass, and other kilns that operate at high temperatures.

Petrochemical Equipment: Ideal for chemical processes that involve high heat and corrosive gases.

Pros and Cons of 309 Stainless Steel

Advantages

- Superior High-Temperature Resistance: Withstands up to 2000°F, making it perfect for high-heat applications.

- Excellent Corrosion Resistance: Provides long-term resistance to oxidation in high-temperature environments.

- Versatile Applications: Useful in various industries, from petrochemical to food processing.

- Good Weldability: It can be welded using most conventional methods.

Disadvantages

- Cost: More expensive than lower-grade stainless steels such as 304 or 316, because of its specialized properties.

- Work Hardening: Has a high work-hardening rate, which may make machining more difficult.

- Limited Cold Forming: While it can be cold worked, this grade is less malleable than lower-alloyed steels.

Welding of 309 Stainless Steel

Welding is a common processing method for 309 stainless steel. The following introduces the main welding methods of 309 stainless steel and the key points of welding with carbon steel.

Main welding methods

TIG welding: TIG welding (tungsten inert gas shielded welding) is suitable for high-precision welding, and ER309 or ER309L is often used as filler material. Argon protection prevents oxidation and is suitable for applications with high weld quality requirements.

MIG welding: MIG welding (molten inert gas shielded welding) is used for fast welding of thicker materials, using ER309 welding wire, low heat input during welding, and suitable for large-area welding.

Arc welding: Arc welding (SMAW) using E309 or E309L electrodes is suitable for on-site construction and maintenance, and can provide high-strength, high-temperature resistant welds.

Resistance welding: Suitable for batch welding of small parts, such as spot welding or seam welding, and precise control of welding parameters is required to avoid deformation.

Welding of 309 stainless steel to carbon steel

When welding 309 stainless steel to carbon steel, it is key to use ER309 or E309 welding rods as filler materials to compensate for the difference in thermal expansion of the two materials and prevent weld cracking. Control heat input and avoid excessive welding temperatures to reduce stress concentration in the heat-affected zone. In addition, proper heat treatment is required after welding to eliminate stress and enhance joint performance.

Occasions for welding 309 stainless steel to carbon steel include the following:

Boilers and pressure vessels: The high temperature resistance of 309 stainless steel makes it suitable for use in high temperature areas of boilers and pressure vessels, while carbon steel is used in low temperature areas.

Chemical equipment: In some chemical equipment, 309 stainless steel and carbon steel are often used in different parts of the same structure, combining high temperature resistance and corrosion resistance.

Automotive industry: Some exhaust systems use 309 stainless steel welded to carbon steel to increase the high temperature durability of exhaust components.

Processing Methods of 309 Stainless Steel

309 stainless steel can be processed through several methods. These processes enhance the material’s properties, making it suitable for specific applications.

Forming

309 stainless steel has good formability due to its austenitic structure, allowing it to be bent, formed, and shaped without cracking. It is suitable for various forming processes, such as deep drawing and roll forming. However, because of its high strength, higher force may be required compared to other grades of stainless steel.

Cutting

Cutting 309 stainless steel can be done using standard methods such as:

- Plasma cutting

- Laser cutting

- Water jet cutting

- Mechanical cutting using sawing or shearing

Due to its hardness, higher wear resistance, and toughness, cutting tools need to be optimized for prolonged tool life. High-speed steel or carbide-tipped cutting tools are recommended for precision cutting.

Hot Working

309 stainless steel is well-suited for hot working processes like forging, hot rolling, and extrusion. It retains its strength at high temperatures, making it ideal for such applications.

- Forging temperature: The material should be heated to a temperature between 1175°C to 1260°C (2150°F to 2300°F). It should be hot worked above 982°C (1800°F) to avoid cracking and deformation.

- Post-hot working: Air cooling or rapid quenching is recommended to avoid grain growth and ensure proper microstructure.

Cold Working

Cold working methods such as stamping, drawing, and cold rolling can be applied to 309 stainless steel, but the material will harden more quickly than other austenitic steels due to its higher chromium and nickel content.

- Work hardening occurs rapidly, increasing the strength and hardness of the material. Intermediate annealing may be required for extensive cold working operations.

Heat Treatment

Heat treatment is commonly performed on 309 stainless steel to relieve stress and enhance ductility.

- Annealing: Full annealing is done by heating to 1040°C to 1150°C (1900°F to 2100°F), followed by rapid cooling (usually in water or air). This process restores the material’s ductility after cold working and enhances corrosion resistance.

- Stress relieving: For stress relief after machining or welding, the material can be heated to 400°C to 800°C (750°F to 1475°F).

Surface Treatment

309 stainless steel can undergo various surface treatments to improve its aesthetics or enhance corrosion resistance.

- Pickling: This process removes the oxide scale after hot working or heat treatment.

- Electropolishing: Used to produce a smooth, mirror-like finish, improving surface cleanliness and corrosion resistance.

- Passivation: Enhances the protective chromium oxide layer on the steel surface, increasing its corrosion resistance in harsh environments.

These methods ensure that 309 stainless steel performs optimally across a wide range of high-temperature and corrosion-resistant applications.

Difference between 309 and Other Grades

Is 309 stainless better than 304?

Yes, 309 stainless steel is better than 304 in high-temperature and corrosive environments due to its higher chromium (22-24%) and nickel (12-15%) content. It withstands temperatures up to 1100°C (1900°F), making it ideal for applications like furnaces and heat exchangers.

However, for general applications, 304 stainless steel is more versatile, easier to form, weld, and more cost-effective. It handles lower temperatures (up to 870°C or 1600°F) and is commonly used in kitchen appliances, household items, and architectural decoration.

Is 308 or 309 better for stainless to stainless steel?

Yes, 309 stainless steel is generally better than 308 for welding stainless to stainless in high-temperature environments.

309 stainless steel has higher chromium and nickel content than 308, giving it superior heat resistance and oxidation resistance. It is often preferred for welding stainless steel where the joint may experience elevated temperatures or harsh environments.

308 stainless steel is typically used for welding lower-grade stainless steels (such as 304), and it performs well in standard conditions. However, if heat resistance or exposure to extreme temperatures is required, 309 is the better choice.

309 stainless steel vs 316

316 stainless steel contains molybdenum, which enhances its corrosion resistance and is more suitable for environments where corrosion resistance is required. 309, on the other hand, is designed for high temperature resistance and does not contain molybdenum. 316 is used in marine and chemical processing environments, while 309 is used in furnace linings and industrial heaters.

309 stainless steel vs 310

310 stainless steel contains higher amounts of chromium (25%) and nickel (20%) compared to 309, which improves its heat resistance even further. 310 can withstand temperatures up to 2100°F (1149°C), making it ideal for extreme heat applications like incinerators and boilers. In comparison, 309 is better suited for slightly lower temperature environments, around 1900°F (1038°C), but still excels in many high-heat industrial uses.

309 stainless steel vs 321

321 stainless steel contains titanium, which prevents intergranular corrosion at high temperatures, making it stable in environments between 800-1500°F (427-816°C). While 321 is designed for resistance to thermal fatigue and stress, 309’s strength lies in its higher temperature tolerance, making it suitable for furnace components and heat exchangers. In contrast, 321 is often used in aerospace applications, such as exhaust systems and high-temperature ducting.

309 stainless steel vs 409

409 stainless steel is a ferritic stainless steel with lower chromium content (10.5-11.75%) and no nickel. This makes it less resistant to both corrosion and high temperatures compared to 309. 409 is mainly used in automotive exhaust systems and industrial pipes, where the environment is less demanding in terms of heat and corrosion. In contrast, 309 is used in high-temperature applications due to its superior heat and oxidation resistance.

Is 309 Stainless Steel Magnetic?

In its annealed form, 309 stainless steel is generally non-magnetic. However, cold working can induce slight magnetism, especially in applications that require forming or machining.

Does 309 Stainless Steel Rust?

309 stainless steel is highly resistant to rust and corrosion, particularly in high-temperature environments. However, like all stainless steels, it can rust if exposed to environments containing high concentrations of chloride or other corrosive substances, especially when not properly treated or maintained.

309 Stainless Steel Manufacturers

SteelPRO Group is a leading global manufacturer and supplier of 309 stainless steel products. As one of the top China 309 stainless steel manufacturers, their specialized 309 stainless steel plate factory ensures top-notch production standards, meeting the needs of various high-temperature applications.

High-Quality Products: SteelPRO Group provides premium-grade 309 stainless steel plates, sheets, rods, and coils, ensuring reliable performance and adherence to international standards.

Leading China Manufacturer: As a trusted China 309 stainless steel manufacturer, they offer large-scale, high-quality production with advanced technology, serving both domestic and international markets.

Specialized Factory: Their 309 stainless steel factory focuses on producing custom-sized 309 pipes, plates, bars, etc., for demanding applications, such as furnaces and heat exchangers.

Comprehensive Product Range: SteelPRO Group offers a wide variety of 309 stainless steel forms, ensuring customers can source all their material needs from one trusted supplier.

Custom Solutions: With flexible production capabilities, they deliver tailored solutions for specific project requirements, ensuring clients get exactly what they need.

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons