Contents

405 Stainless Steel: Forms, Composition, Properties, Applications, Processing and More

- John

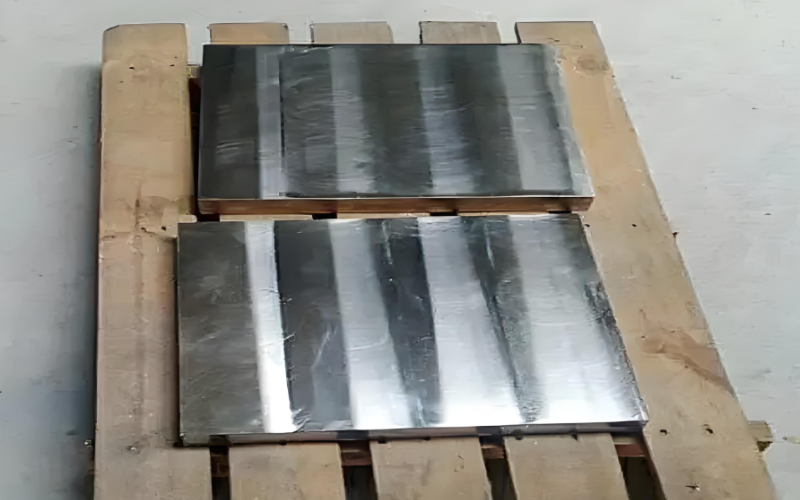

Here we introduce the chemical composition, characteristics, applications, advantages and disadvantages, processing methods of 405 stainless steel, and its differences from 304 and 410 stainless steel. Our SS 405 products include plates, coils, bars, tubes, etc. We can provide high-quality solutions, whether you need standard sizes or customized specifications.

What is 405 Stainless Steel?

405 stainless steel is a ferritic stainless steel containing approximately 12% chromium that is low cost, easily formed, and has a low (but weak) resistance to oxidation and corrosion. It does not harden after exposure to high temperatures, making it suitable for welding and forming applications, while maintaining good softness and ductility.

405 stainless steel equivalent grades

Here are the equivalent grades of 405 stainless steel under different specifications:

- UNS: S40500

- EN: X6CrAl13 (1.4002)

- JIS: SUS405

- BS: 405S17

Standard of 405 stainless steel

- ASTM A176

- ASTM A240

- ASTM A268

- ASTM A276

- ASTM A314

- ASTM A473

- ASTM A479

- ASTM A511

- ASTM A580

Chemical Composition of 405 Stainless Steel

| Element | Composition Range |

| Carbon (C) | 0.08% max |

| Chromium (Cr) | 11.5% – 14.5% |

| Manganese (Mn) | 1.00% max |

| Silicon (Si) | 1.00% max |

| Sulfur (S) | 0.03% max |

| Phosphorus (P) | 0.04% max |

| Nickel (Ni) | 0.50% max |

| Aluminum (Al) | 0.10% – 0.30% |

The relatively high chromium content (11.5-14.5%) provides enhanced oxidation resistance, while the addition of aluminum improves the steel’s stability at elevated temperatures. The controlled carbon content ensures that 405 stainless steel maintains its ductility and machinability.

405 Stainless Steel Properties

Key Features of 405 Stainless Steel

405 stainless steel offers a unique combination of features that make it suitable for various industrial applications. Here’s a closer look at some of its key features:

Corrosion Resistance: Although not as corrosion-resistant as 304 or 316 stainless steel, 405 offers good resistance to atmospheric and mild environmental corrosion. It is particularly suitable for applications with limited exposure to harsh chemicals or salt water.

Weldability: Compared to other ferritic stainless steels, 405 has excellent weldability. It can be welded using most standard methods, and post-weld annealing enhances its ductility, allowing for further shaping and processing.

Magnetic Properties: 405 is a ferritic stainless steel, meaning it is magnetic.

Oxidation Resistance: 405 stainless steel can withstand oxidation at temperatures up to 800°C, making it ideal for use in high-temperature environments like furnace components and heat exchangers.

Cost-Effective: Compared to other stainless steel grades like 304 or 316, 405 is more affordable due to its lower nickel content.

Mechanical Properties

| Property | Metric | Imperial |

| Tensile Strength (Ultimate) | 415 – 469 MPa | 60,000 – 68,000 psi |

| Yield Strength (0.2% offset) | 170 – 276 MPa | 25,000 – 40,000 psi |

| Elongation at Break (in 50 mm) | 20 – 30% | 20 – 30% |

| Hardness (Rockwell B) | Max 88 HRB | Max 88 HRB |

| Hardness (Brinell) | 131 – 179 HB | 131 – 179 HB |

| Elastic Modulus (Tension) | 200 GPa | 29 x 10^6 psi |

| Poisson’s Ratio | 0.27 – 0.30 | 0.27 – 0.30 |

| Impact Strength (20°C) | 41 J | 30.2 ft-lb |

| Reduction in Area | 40 – 60% | 40 – 60% |

Thermal and Physical Properties

| Property | Metric | Imperial |

| Density | 7.80 g/cm³ | 0.282 lb/in³ |

| Thermal Conductivity (0-100°C) | 27 W/m·K | 187 BTU-in/hr-ft²-°F |

| Coefficient of Thermal Expansion (0-100°C) | 10.8 µm/m-°C | 6 µin/in-°F |

| Specific Heat (0-100°C) | 0.460 J/g-°C | 0.110 BTU/lb-°F |

| Electrical Resistivity (20°C) | 0.000060 ohm-cm | 0.000060 ohm-cm |

| Melting Point | 1480 – 1530°C | 2700 – 2790°F |

| Maximum Operating Temperature (Air) | 705°C | 1300°F |

| Modulus of Elasticity | 200 GPa | 29 x 10^6 psi |

Forms of 405 Stainless Steel

Our 405 stainless steel products come in a variety of forms to suit different industrial applications:

- Plates: 405 stainless steel plates are commonly used in structural applications and for manufacturing large components.

- Sheets: Thin 405 stainless steel sheets are used for parts that require precision and detailed shaping, such as automotive and industrial parts.

- Coils: Coiled stainless steel is often used in continuous production lines for high-volume manufacturing.

- Bars (round, square, flat): Bars of various shapes are used in construction, machinery, and equipment manufacturing.

- Pipes and Tubes (seamless and welded): These are used in piping systems for transporting fluids and gases in industries like oil and gas.

- Fittings and Flanges: These components are used in pipeline systems where secure connections are required.

- Wires: Stainless steel wires are commonly used in welding, construction, and various manufacturing processes.

Application of 405 Stainless Steel

Thanks to its unique combination of mechanical and thermal properties, 405 stainless steel finds its use in various industries and applications.

Annealing Boxes: 405 stainless steel’s resilience to high temperatures and ability to retain structural integrity render it an ideal material for annealing boxes.

Steam Nozzles: Its resistance to oxidation at high temperatures makes it a suitable material for steam nozzle fabrication.

Quenching Racks: Due to its capability to withstand rapid temperature fluctuations without experiencing deformation, 405 stainless steel is frequently utilized in quenching racks.

Partitions: The material’s strength and formability allow it to be used in industrial partitions, particularly in high-temperature environments.

Automotive Exhaust Systems: 405 stainless steel’s resistance to heat and oxidation makes it ideal for use in automotive exhaust components like mufflers and exhaust manifolds.

Pros and Cons of 405 Stainless Steel

Advantages

- Cost-effective: Compared to austenitic stainless steels like 304 and 316, 405 is more affordable due to its lower nickel content.

- Good Weldability: It can be welded using most standard techniques without the need for specialized processes.

- High-temperature Resistance: It exhibits exceptional performance in high-temperature environments, effectively resisting oxidation and scaling even at temperatures reaching up to 800°C.

- Magnetic: Its magnetic properties make it suitable for applications where magnetism is required.

- Easily Machinable: The soft and ductile nature of 405 stainless steel facilitates its machining and shaping into intricate forms, making it an ideal material for intricate designs.

Disadvantages

- Lower Corrosion Resistance: Compared to other stainless steel grades, its corrosion resistance is relatively lower, limiting its use in highly corrosive environments.

- Not Hardenable by Heat Treatment: Unlike martensitic grades, 405 cannot be hardened by heat treatment, limiting its use in applications that require very high strength.

What Are the Processing Methods of 405 Stainless Steel?

Forming

- Cold Forming: 405 stainless steel can be cold formed, but it has lower ductility than austenitic stainless steels like 302 or 304. Forming is generally limited to simpler shapes, and annealing may be needed afterward to reduce internal stresses.

- Deep Drawing: While it can be drawn, its formability is not as high as other stainless steels, so it’s more suited to less complex shapes.

Welding

- Weldability: 405 stainless steel is specifically designed to improve weldability. It contains added aluminum to prevent grain growth, which makes it less prone to cracking during welding. It can be welded using TIG, MIG, or resistance welding techniques.

- Post-Weld Annealing: Typically not necessary for 405 stainless steel due to its ferritic structure, which naturally resists stress corrosion cracking, but it can be used to relieve residual stresses.

Cutting

- Laser Cutting: Laser cutting is effective for 405 stainless steel, especially for thin sections. It provides clean and precise cuts without inducing much heat.

- Plasma Cutting: Suitable for thicker sections where higher cutting speeds are needed, though it can introduce heat-affected zones.

- Mechanical Cutting (Shearing): This method works well for 405 stainless steel. The material’s relatively lower toughness compared to austenitic grades makes it easier to shear.

Hot Working

405 stainless steel can undergo hot working processes, but specific precautions are necessary:

- Forging: Hot forging should be carried out at temperatures ranging from 1100°C to 1300°C (2012°F to 2372°F). The material should be annealed after forging to restore its properties and prevent brittleness.

- Hot Rolling: Suitable for shaping the material into desired forms, hot rolling helps achieve improved mechanical properties and is ideal for thicker sections.

- Extrusion: This process can be used for 405 stainless steel at high temperatures, but temperature control is critical to avoid brittleness.

Cold Working

- Cold Rolling: 405 stainless steel can be cold-rolled into thinner sections, though its lower ductility compared to austenitic grades means it is not as easily formed in cold working operations.

- Cold Bending: Simple bending is possible, but more complex or tight bends might result in cracking unless the material is properly annealed after forming.

Heat Treatment

- Annealing: Annealing 405 stainless steel should be done at temperatures between 700°C and 800°C (1292°F to 1472°F) to soften the material after cold working or to relieve residual stresses.

- Stress Relieving: Low-temperature stress-relief treatments can be performed at temperatures between 150°C and 300°C (302°F to 572°F) to reduce internal stresses without significantly affecting mechanical properties.

- Normalizing: Not generally necessary for 405, as it is already a stabilized ferritic steel with limited grain growth during high-temperature processing.

Surface Treatment

- Electropolishing: It can be used to improve surface finish and enhance corrosion resistance, but it is less commonly applied to ferritic stainless steels like 405.

- Pickling and Passivation: 405 stainless steel can undergo pickling to remove scale and contaminants. It can be passivated to enhance corrosion resistance, though its inherent resistance is lower compared to austenitic grades.

- Polishing: Mechanical polishing is possible, although ferritic stainless steels like 405 do not achieve as high a polish as austenitic grades due to their microstructure.

What is the Difference Between 304, 410 and 405 Stainless Steel?

The stainless steel grades 304, 410 and 405 each have distinct characteristics.

405 vs 410 Stainless Steel

- Corrosion Resistance: 405 has better corrosion resistance than 410. 410 is more prone to rust, especially in moist or corrosive environments.

- Hardening: 410 can be hardened through heat treatment, making it stronger and more wear-resistant. 405 cannot be hardened and is softer.

- Weldability: 405 is designed for better weldability, while 410 is more challenging to weld due to its martensitic structure, which can crack.

- Applications: 405 is preferred in applications requiring good weldability and moderate corrosion resistance (e.g., heat exchangers), while 410 is better for high-strength applications (e.g., cutting tools, springs).

304 vs 405 Stainless Steel

- Corrosion Resistance: 304 has superior corrosion resistance compared to 405, particularly in harsh environments (acidic or chloride-rich). 405 is suitable for less demanding conditions.

- Weldability: Both are weldable, but 304 is easier to weld and does not require special treatment for stabilization. 405 has added aluminum to prevent grain growth during welding.

- Cost: 405 is generally cheaper than 304 due to its lower nickel content.

- Applications: 304 is used in more corrosive environments like food processing, chemical containers, while 405 is used in applications where cost-efficiency and moderate corrosion resistance are sufficient, such as automotive components.

Is 405 Stainless Steel Magnetic?

Yes, 405 stainless steel has a certain degree of magnetism. This is because it is a ferritic stainless steel, the main components of which are iron, chromium and a small amount of nickel. This structure makes it exhibit a certain degree of magnetism at room temperature.

405 Stainless Steel Manufacturer

SteelPRO Group is a 405 stainless steel manufacturer and supplier that offers high-quality products and exceptional customer service.

Extensive Product Range: SteelPRO Group offers a comprehensive range of 405 stainless steel products, including plates, sheets, coils, bars and tubes, and can also meet different customized requirements.

Quality Assurance: Our products are manufactured in accordance with international standards such as ASTM, JIS and DIN, ensuring consistent quality. SteelPRO Group is ISO 9001 certified, guaranteeing first-class quality control processes.

Technical Support: Our team of experts can provide technical advice to help you choose the most appropriate 405 stainless steel product for your specific application. We also provide comprehensive after-sales support to ensure your project goes smoothly.

Timely Delivery: SteelPRO Group has a well-established global supply network, allowing us to serve customers around the world with fast and efficient logistics solutions.

Welcome to contact SteelPRO Group to explore our full range of stainless steel products.

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons