Contents

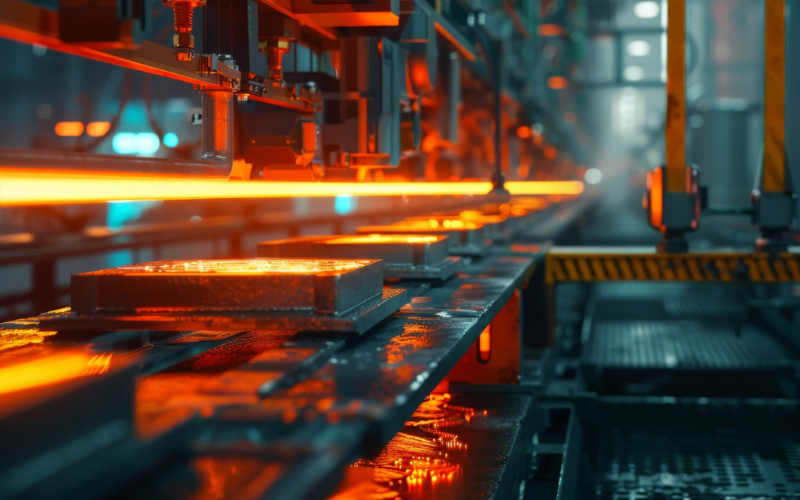

Annealed Stainless Steel | Principle, Performance, Application and Comparative Analysis

- John

We aim to deeply explore the principles and steps of stainless steel annealing process and its influence on material properties, analyze the application of annealed stainless steel in various fields, compare the differences between annealing and tempering treatment, and explain the annealing characteristics of different grades of stainless steel to make it more convenient for you to select, process and store stainless steel materials.

What is Annealed Stainless Steel?

Annealed stainless steel refers to stainless steel that has been treated by an annealing process to obtain specific properties. Annealing is a heat treatment that involves heating to a specific temperature followed by slow cooling to reduce internal stresses, increase ductility, and soften the material. As a result, annealed stainless steel has better machinability, formability and corrosion resistance than untreated steel.

What is annealing?

Annealing is a heat treatment that softens materials, making them more ductile and easier to work with. It involves heating, holding, and slowly cooling to improve the material’s structure and reduce internal stresses. This process is used for metals like steel, copper, and brass, as well as glass and plastics.

What Is the Purpose of Stainless Steel Annealing?

1. Eliminate internal stress

In the manufacturing and processing of stainless steel, such as casting, forging, welding, cold working, etc., different degrees of internal stress will be introduced. If these internal stresses are not eliminated in time, the material will deform and crack during use. Annealing treatment releases internal stress through uniform heating and slow cooling, thereby improving the dimensional stability and service life of the material.

2. Stabilize organization and performance

Annealing can cause the crystal structure inside stainless steel to rearrange and form a more uniform and stable organization. This improvement in organization structure helps to improve the corrosion resistance, mechanical properties and processing performance of the material, so that stainless steel can maintain good use in a wider range of environments and conditions.

3. Improve processing performance

The processing performance of annealed stainless steel will be significantly improved due to the reduction of internal stress and refinement of organization. For example, annealing treatment can reduce the hardness of the material, improve its plasticity and toughness, make stainless steel easier to operate in subsequent cutting, bending, stamping and other processing processes, and reduce scrap rate and processing costs.

How to Anneal Stainless Steel?

Annealing process

Cleaning the stainless steel surface: remove surface impurities, oil stains and oxide layers to ensure that the surface is clean and tidy.

Inspect the stainless steel material: confirm the type, specification and quality of the stainless steel to ensure that it meets the annealing process requirements.

Determine the annealing temperature and time: determine the appropriate annealing temperature and time according to the type and thickness of the stainless steel. Annealing temperature is usually between 600℃-1100℃, and the holding time is generally 30 minutes to several hours.

Annealing process control: During the annealing process, it is necessary to control the temperature uniformity, atmosphere environment and cooling rate to ensure the desired structure and performance.

Annealing post-treatment: After annealing, check the surface quality of the stainless steel. If necessary, pickling or sandblasting is performed to remove the oxide scale, and subsequent processing and straightening are performed to meet product requirements.

Process parameters

Annealing temperature: It is one of the key factors affecting the performance of stainless steel. Excessive temperatures can lead to metal overburning, while inadequate temperatures may render the annealing process ineffective. The annealing temperature of stainless steel should be determined according to its type and thickness.

Annealing time: It is determined according to the thickness of the metal and the annealing temperature to ensure that the stress inside the metal is completely eliminated and not overburdened.

Cooling rate: It also affects the performance of stainless steel. Rapid cooling can refine the grains of the metal and improve its strength and toughness; slow cooling helps to eliminate internal stress and improve the plasticity and processing properties of the metal.

Classification of annealing process

According to different stainless steel types and application requirements, annealing processes can be divided into several different types.

Full annealing: The stainless steel is heated to above the recrystallization temperature and then slowly cooled, which is usually used to improve the ductility and plasticity of the material.

Solution annealing: Mainly used for austenitic stainless steel, heated to the solution temperature range, and then quickly cooled to eliminate the precipitation phase and restore the uniformity of the material.

Subcritical annealing: Applicable to some low-carbon and ferritic stainless steels, heated and slowly cooled in a range below the critical temperature to reduce hardness and improve machinability.

Properties of Annealed Stainless Steel

Annealing has a profound effect on the properties of stainless steel.

- First, it significantly softens the material, increasing its plasticity and toughness, thereby reducing the risk of fracture under impact loads. This improved flexibility also facilitates subsequent machining and forming operations.

- Annealing improves the corrosion resistance of stainless steel by refining the internal crystal structure of the stainless steel, mitigating grain boundary defects and reducing corrosion initiation sites. As a result, annealed stainless steel exhibits superior durability in harsh environments.

- In addition, annealed stainless steel also shows better dimensional stability and processing performance, and can meet higher precision processing requirements.

What Is Annealed Stainless Steel Used for?

Due to its excellent performance characteristics, annealed stainless steel is widely used in various fields.

- In the chemical, petroleum, pharmaceutical and other industries, annealed stainless steel has become the preferred material for manufacturing various containers, pipes and equipment due to its good corrosion resistance and stability.

- Annealed stainless steel is widely preferred in food processing and medical equipment industries due to its non-toxic, innocuous nature, and ease of cleaning.

- The beautiful appearance and excellent performance of annealed stainless steel make it a popular material in various industries such as construction, decoration and automobile manufacturing.

How to Store Annealed Stainless Steel?

The storage of annealed stainless steel needs to pay attention to the following points.

- Maintain a dry, well-ventilated storage environment and avoid contact with corrosive substances to prevent surface corrosion and rust.

- In order to maintain the beauty and functionality of stainless steel, special attention should be paid to avoid mechanical damage and scratches on its surface.

- During transportation and handling, special care must be taken to prevent collisions and falls to ensure that the integrity of the material is not affected.

Different Grades of Annealed Stainless Steel

Is 316 stainless steel annealed?

Annealed 316 stainless steel exhibits enhanced corrosion resistance and processing characteristics, making it ideal for applications requiring stringent standards and high performance.

Is 304 stainless steel annealed?

304 stainless steel is annealed to resolve internal stress, stabilize its microstructure and further improve its performance. Annealed 304 stainless steel has strong corrosion resistance and excellent processing capabilities, and is widely used in various industries and fields.

Common annealed stainless steel grades

Except the 316 and 304 stainless steel types mentioned above, there are many other commonly used stainless steel grades on the market that are annealed to improve their overall properties.

The inclusion of titanium in 321 stainless steel enhances its intergranular corrosion resistance. Post-annealing, its exceptional properties position it as a premier selection for high-temperature applications.

430 stainless steel is a ferritic variant that, while not as corrosion resistant as austenitic grades such as 304 and 316, has significantly increased plasticity and toughness after annealing. This makes it a popular choice for decorative applications, cookware, and various other industries.

Duplex stainless steels, such as 2205 or S31803, and super duplex stainless steels, such as 2507 or S32750, not only maintain their excellent corrosion resistance after annealing, but also have high strength and excellent weldability. These properties make them well suited for the challenging environments encountered in offshore engineering and chemical equipment.

Annealed Stainless Steel Forms

Annealed stainless steel comes in several common forms, each tailored for different industrial uses:

- Annealed stainless steel sheet and plate: Used in construction, automotive, and appliances due to their durability and corrosion resistance.

- Annealed stainless steel rod and bar: Employed in machining and manufacturing for making components like fasteners, gears, and shafts.

- Annealed stainless steel tubes and pipe: Utilized in industries such as oil and gas, chemical processing, and plumbing for fluid and gas transport.

- Annealed stainless steel wire: Often used in medical, aerospace, and electronics industries for applications requiring flexibility and strength.

Each form benefits from the annealing process, which enhances its workability and mechanical properties.

Annealing Stainless Steel vs. Steel

Compared with ordinary steel, annealed stainless steel performs better in many key properties. Annealed stainless steel has significantly higher corrosion resistance than ordinary steel, especially in chloride-containing or acidic environments. Annealed stainless steel also has better ductility and machinability, which enables it to perform better in the manufacture of complex parts. Annealed stainless steel usually has a higher surface quality, and after proper treatment, it can achieve a mirror effect, which is particularly important in areas such as architectural decoration that require high appearance quality.

However, the cost of annealed stainless steel is usually higher than that of ordinary steel, so when selecting materials, the relationship between cost and performance must be weighed.

What Is the Difference between Annealed and Unannealed Stainless Steel?

The primary difference between annealed and unannealed stainless steel lies in their mechanical properties, resulting from the annealing heat treatment process. In summary, annealed stainless steel is softer, more ductile, and easier to work with, while unannealed stainless steel is harder, stronger, but less workable.

1. Hardness and Ductility:

- Annealed Stainless Steel: This is softer and more ductile. The annealing process relieves internal stresses, making the material easier to form, bend, or machine without cracking. It also increases flexibility.

- Unannealed Stainless Steel: Also known as work-hardened or cold-worked, unannealed stainless steel is harder and more brittle. It has undergone processes like rolling or forging, which increase its strength but make it less ductile and more prone to cracking during shaping.

2. Internal Stresses:

- Annealed: The annealing process eliminates internal stresses caused by manufacturing processes like welding or cold working, making the material more stable.

- Unannealed: Residual stresses are present, which may cause warping or cracking over time, especially under load or thermal stress.

3. Workability:

- Annealed: Easier to machine, shape, or form due to its lower hardness.

- Unannealed: More difficult to machine and may require more force for forming or shaping due to its higher hardness.

4. Strength:

- Annealed: Generally has lower tensile strength compared to unannealed stainless steel but is more flexible.

- Unannealed: Higher tensile strength, making it stronger and better suited for applications requiring load-bearing capacity.

5. Applications:

- Annealed: Preferred for applications where ease of machining, forming, or shaping is required, such as in manufacturing, plumbing, or construction.

- Unannealed: Often used in situations where high strength is necessary, like in structural components or high-wear parts.

Other Stainless Steel Heat Treatment Processes

In addition to annealing, stainless steel may also use other heat treatment processes to improve its performance. For example:

Solution treatment

Stainless steel is heated to a certain temperature (usually above its critical point), kept for a certain period of time, and then quickly cooled to eliminate precipitation phases and residual stresses in the material, and improve the corrosion resistance and toughness of the material.

Aging treatment

Aging treatment can further improve the strength and hardness of stainless steel. This is usually carried out after solution treatment. By keeping the material at a certain temperature for a long time, phase transformation or precipitation of strengthening phase occurs inside the material.

Cold treatment

For some special stainless steels, such as occasions where extremely high strength and toughness are required, cold treatment processes may be used. This includes cryogenic treatment (cooling the material to an extremely low temperature) and liquid nitrogen treatment.

Does Annealing Increase Hardness?

No, annealing reduces hardness. Its main purpose is to soften the material and increase ductility, making it easier to work with.

Pros and Cons of Annealing

Advantages of Annealing:

- Increased Ductility: Makes the material easier to shape and form.

- Reduced Hardness: Softens the metal, making it easier to machine and work with.

- Relieves Internal Stresses: Prevents warping or cracking during further processing.

- Improved Material Stability: Refines grain structure, enhancing toughness and uniformity.

Disadvantages of Annealing:

- Surface Oxidation: Can cause scaling or oxidation on the material’s surface during heating.

- Time-Consuming: The process can take a long time due to slow cooling.

- Reduced Strength: Softening reduces the material’s hardness and tensile strength.

- Energy-Intensive: Requires significant energy for heating and maintaining temperature.

Annealing vs Tempering

Annealing and tempering are both heat treatment processes used to improve the properties of metals, but they serve different purposes and involve different methods:

1. Purpose:

- Annealing: The primary goal of annealing is to soften the material, improve its ductility, and relieve internal stresses. This makes the metal easier to work with in processes like shaping, bending, or machining.

- Tempering: Tempering aims to reduce the brittleness of hardened metal, specifically after a hardening process like quenching. It balances hardness and toughness, preventing the material from being too brittle.

2. Process:

- Annealing: The material is heated to a temperature above its recrystallization point, held at that temperature, and then slowly cooled (usually in a furnace). This slow cooling refines the grain structure and softens the metal.

- Tempering: After quenching (a hardening process), the metal is reheated to a lower temperature than that used for annealing. It’s then held at that temperature for a specific period and cooled, which reduces brittleness without removing all the hardness.

3. Effects on Material Properties:

- Annealing: Makes the material softer, more ductile, and easier to shape. It reduces hardness and tensile strength but improves workability.

- Tempering: Lowers the brittleness while retaining a significant amount of hardness, making the material tougher and more resistant to fractures.

4. Typical Applications:

- Annealing: Used for metals that need further shaping, forming, or machining, such as sheet metal, wire, or tubes. It’s also commonly used in processes involving steel, copper, and aluminum.

- Tempering: Applied after quenching to hardened materials like high-carbon steels, tools, and blades, where a balance between hardness and toughness is essential for performance under stress.

5. Common Temperatures:

- Annealing: High temperatures, usually above the material’s recrystallization temperature (often around 500–900°C for steel).

- Tempering: Lower temperatures, typically between 150–650°C, depending on the material and desired properties.

What Is the Difference between Hardened and Annealed Steel?

Hardened steel is strengthened through heat treatment, making it hard and wear-resistant but brittle due to internal stresses from rapid cooling. It’s used in tools and high-strength components.

Annealed steel, in contrast, is softened by slow cooling, making it more ductile, stable, and easier to shape or machine. While not as strong as hardened steel, it’s ideal for applications requiring flexibility and workability

China Annealed Stainless Steel Manufacturer

SteelPRO Group is a stainless steel manufacturer and supplier. Our annealed stainless steel factory provides annealed stainless steel in various forms and grades, including 316, 304, 321, 303, 420, 430, 201, 17-4, 18-8, 347, 410, 416, etc. annealed stainless steel in plates, sheets, coils, bars and wires.

SteelPRO Group works with heat treatment experts to provide customers with customized high-quality steel parts and reliable after-sales service. We have a wide range of inventory to meet your diverse needs. Contact us now or continue browsing our blog to explore your exclusive solution.

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons