Contents

18/10 Stainless Steel: Composition, Properties, and Applications

- John

When selecting stainless steel for your cookware, cutlery, or even medical devices, you may have come across the term “18/10 stainless steel”. This stainless steel is recognized for its superior quality and endurance. But what exactly does “18/10” mean, and why is it so highly regarded? In this blog, we will explore the composition, properties, and applications of 18/10 stainless steel and so on.

What Is 18/10 Stainless Steel?

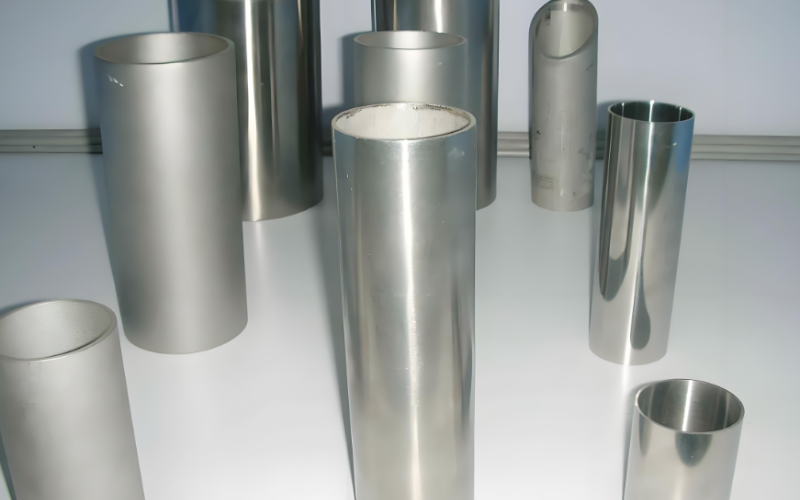

18/10 stainless steel, also known as 304 stainless steel, is an alloy composed of 72% iron, 18% chromium, and 10% nickel, known for its solid form and shiny, polished appearance. Chromium gives corrosion resistance, while nickel increases strength and toughness. Produced through hot rolling, this high-quality stainless steel is durable, non-reactive, and easy to clean. It is used for kitchenware, cutlery, medical instruments, industrial applications, construction, and jewelry.

What Does 18/10 Stainless Steel Mean?

The term “18/10” in stainless steel refers to its composition of 18% chromium and 10% nickel. Chromium provides corrosion resistance and prevents rusting and staining by forming a protective surface layer, while nickel enhances this corrosion resistance and adds strength. This combination makes 18/10 stainless steel resistant to rust, strong, durable, and visually appealing, ideal for high-quality kitchenware, cutlery, and medical instruments, ensuring long-lasting performance and a sleek appearance.

What Is the Chemical Composition of 18/10 Stainless Steel?

18/10 stainless steel primarily consists of 18% chromium and 10% nickel, with the remainder being iron and small amounts of other elements. This composition imparts distinctive properties, including superior corrosion resistance, strength, and durability.

| Element | Composition (Weight %) |

| Chromium (Cr) | 18.0-20.0% |

| Nickel (Ni) | 8.0-10.5% |

| Carbon (C) | ≤ 0.08% |

| Manganese (Mn) | ≤ 2.00% |

| Silicon (Si) | ≤ 1% |

| Phosphorus (P) | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% |

| Nitrogen (N) | ≤ 0.10% |

| Iron (Fe) | Balance |

Chromium

Chromium is critical in making stainless steel resistant to corrosion and rust. In 18/10 stainless steel, the 18% chromium forms a thin chromium oxide layer on the surface that prevents rust. If scratched or damaged, the layer self-repairs by forming a new protective coating through the reaction of chromium with oxygen.

Nickel

Nickel is added to enhance the corrosion resistance provided by chromium. The 10% nickel in 18/10 stainless steel also improves its overall strength and toughness, making it more durable and resistant to damage. Nickel gives the steel a shiny, attractive appearance, which is why 18/10 stainless steel is often used for kitchenware and cutlery. Reduced electrical and thermal conductivity due to higher chromium and nickel content.

Iron and Other Elements

The remainder of 18/10 stainless steel is primarily iron, along with small amounts of other elements such as manganese, silicon, and carbon. These added elements improve the manufacturing process and enhance specific steel properties. For example, manganese improves the steel’s hardness and strength, while silicon helps with its deoxidation during production.

What Are the Properties of 18/10 Stainless Steel?

18/10 stainless steel boasts a range of impressive properties, including high density, moderate thermal conductivity, a high melting point, moderate thermal expansion, variable magnetic properties, outstanding durability and strength, high aesthetic appeal, excellent high-temperature resistance, exceptional corrosion resistance, highly non-reactive surface, and ease of cleaning and maintenance.

Physical Properties of 18/10 Stainless Steel

| Property | Metric Unit | Imperial Unit |

| Density | 7.9 g/cm³ | 0.285 lb/in³ |

| Melting Point | 1400-1450°C | 2552-2642°F |

| Thermal Conductivity | 16.2 W/m·K at 100°C | 9.36 BTU/h·ft·°F |

| Thermal Expansion | 16.5 µm/m·K | 9.17 µin/in·°F |

| Modulus of Elasticity | 193 GPa | 28 x 10³ ksi |

High Density

18/10 stainless steel has a density of approximately 7.9 g/cm³. This high density provides a substantial feel and indicates its robustness and quality, making it a preferred material for high-end kitchenware and cutlery.

Moderate Thermal Conductivity

This type of stainless steel has a thermal conductivity of around 16 W/m·K. This moderate thermal conductivity allows it to conduct heat efficiently without overheating, which is crucial for cookware that needs to maintain consistent cooking temperatures.

High Melting Point

18/10 stainless steel has a high melting point of approximately 1400-1450°C. This property makes it ideal for high-temperature applications like ovens and grills.

Moderate Thermal Expansion

With a thermal expansion coefficient of about 16.5 µm/m·K, 18/10 stainless steel expands moderately when heated. Its rate of thermal expansion is 16.5 x 10^-6 mm/m/°C at 20°C. This is important for cookware and other applications that need to maintain their shape and structural integrity under varying temperatures.

Variable Magnetic Properties

While generally non-magnetic, 18/10 stainless steel can exhibit some magnetic properties after being cold-worked. This makes it versatile for applications where both non-magnetic and slightly magnetic properties might be required.

Mechanical Properties of 18/10 Stainless Steel

| Properties | Metric | Imperial |

| Tensile Strength | 515-750 MPa | 74.7-108.8 ksi |

| Yield Strength | 215 MPa | 31.2 ksi |

| Vickers Hardness | 129 HV | 129 HV |

| Brinell Hardness | 123 HB | 123 HB |

| Rockwell Hardness | B70-B90 | B70-B90 |

| Elongation | 40% | 40% |

| Elastic Modulus | 193 GPa | 28 x 10³ ksi |

Outstanding Durability and Strength

The addition of 10% nickel enhances the overall strength and durability of 18/10 stainless steel. This material is less likely to crack or break under stress, ensuring that products made from it have a long lifespan and can withstand daily use.

Excellent High-Temperature Resistance

18/10 stainless steel can endure high temperatures without losing its strength or integrity. This makes it suitable for cookware and other applications where exposure to heat is common. It retains its shape and properties even under prolonged heating, making it a reliable material for various thermal applications.

Other Characteristics

High Aesthetic Appeal

18/10 stainless steel is recognized for its shiny, polished look. The high nickel content provides a smooth, appealing finish, making it ideal for high-end kitchen appliances, cutlery, and decorative items. Its sleek look adds elegance to any setting.

Exceptional Corrosion Resistance

18/10 stainless steel excels in resisting rust and corrosion due to its high chromium. The 18% chromium forms a protective oxide layer on the surface, which prevents rust and maintains the steel’s integrity even in humid and harsh environments. This makes it ideal for kitchenware, cutlery, and medical instruments that are frequently exposed to moisture.

304 stainless steel is susceptible to pitting and stress corrosion cracking in chloride environments. For harsher conditions where 304 is prone to pitting or crevice corrosion from chlorides or acidic environments, 316 stainless steel is often used instead.

Highly Non-reactive Surface

One of the significant advantages of 18/10 stainless steel is its non-reactive surface. Unlike other metals, it does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. This property is crucial for kitchenware and cutlery that are in direct contact with food.

Easy to Clean and Maintain

It is easy to clean and maintain. It is dishwasher safe and can be washed with regular household detergents without harming the surface. Its ability to resist stains and fingerprints ensures that it remains looking new with minimal effort.

What are the Applications of 18/10 Stainless Steel?

18/10 stainless steel is extensively used due to its exceptional properties. Its applications range from kitchenware and cutlery to medical instruments, industrial uses, construction, and even jewelry and fashion.

Kitchenware and Cutlery

18/10 stainless steel is a preferred choice for high-quality kitchenware and cutlery. Its excellent corrosion resistance ensures that utensils remain rust-free, even with frequent washing. The material’s durability and strength make it ideal for everyday use, while its non-reactive surface ensures that food flavors are not altered. Its polished, shiny appearance adds a touch of elegance to any kitchen.

Medical Instruments and Equipment

The hygienic qualities of 18/10 stainless steel make it ideal for medical instruments and equipment. Its smooth, non-porous surface does not harbor bacteria, making it easy to sterilize and maintain. Surgical tools, dental instruments, and hospital equipment often utilize this stainless steel due to its strength, durability, and corrosion resistance, ensuring long-lasting performance in demanding environments.

Industrial Applications

In industrial settings, 18/10 stainless steel is preferred for its strength, durability, and corrosion resistance. It is used in the manufacture of machinery parts, tools, and equipment that must withstand harsh conditions and heavy use. Its resistance to chemical reactions and stability at high temperatures make it ideal for diverse industries, such as food processing, chemical manufacturing, and petrochemicals.

Construction and Architecture

It is also widely used in construction and architecture. Its visual appeal, along with its sturdiness and resistance to rust, makes it an ideal choice for structural components, cladding, railings, and decorative elements. It provides both functionality and visual appeal, contributing to the longevity and beauty of buildings and structures.

Jewelry and Fashion

The attractive, shiny finish of 18/10 stainless steel, along with its durability, makes it a popular material for jewelry and fashion accessories. It does not tarnish or corrode, ensuring that pieces remain beautiful over time. Its hypoallergenic properties also make it suitable for sensitive skin. From watches and bracelets to rings and earrings, 18/10 stainless steel is a preferred choice for stylish, durable fashion items.

What are the industry standards for 304 stainless steel?

304 stainless steel does comply with SAE (Society of Automotive Engineers) standards, while ASTM A240/A240M (American Society for Testing and Materials Standards), specifies the chemical composition and physical properties of 304 stainless steel.

What Are the Equivalent Names for 18/10 Stainless Steel?

18/10 stainless steel is known by various equivalent names and designations across different countries and standards. Here is a table summarizing these equivalents:

| Country | Equivalent Name |

| The European Union | X5CrNi18-10 |

| U.S. | 304 |

| Germany | X5CrNi18-9 |

| Japan | SUS304 |

| France | X5CrNi18-10 |

| England | X5CrNi18-10 |

| Italy | X5CrNi18-10 |

| Russia | 08KH18N10 |

| China | 0Cr18Ni9 |

How Is 18/10 Stainless Steel Made?

18/10 stainless steel is produced through a series of carefully controlled processes that ensure its high quality and durability. Production involves melting, refining, casting, and rolling to attain the optimal composition and properties.

Melting

The primary components—iron, chromium, and nickel—are initially melted in an electric arc furnace. This furnace reaches temperatures above 1500°C (2732°F), ensuring that the metals are fully liquefied and mixed.

Refining

Once melted, the molten steel undergoes refining to remove impurities. This process usually involves argon oxygen decarburization (AOD) or vacuum oxygen decarburization (VOD). These methods help achieve the precise chemical composition required for 18/10 stainless steel.

Casting

The purified molten steel is then shaped into semi-finished products such as billets, blooms, or slabs. These forms serve as the starting material for further processing. Continuous casting is a common method used, providing a consistent and high-quality product.

Hot Rolling

The semi-finished forms are heated and hot-rolled through mills. This reduces the thickness and shapes the steel into sheets or coils. The steel’s mechanical properties and surface finish can be improved through hot rolling.

Annealing

After hot rolling, the steel is annealed by being heated to a specific temperature and then slowly cooled. Annealing relieves internal stresses, improves ductility, and enhances the overall mechanical properties of the steel.

Pickling

The annealed steel is then subjected to pickling, where it is treated with an acid solution to remove any scale or oxide layer formed during the hot rolling and annealing processes. This step ensures a clean, smooth surface.

Cold Rolling (Optional)

For certain applications requiring precise dimensions and superior surface finish, the steel may undergo cold rolling. This process passes the steel through rollers at room temperature, enhancing its strength and hardness through work hardening.

Final Finishing

The final steps include cutting the steel into the desired shapes and sizes, performing any additional surface treatments or coatings as needed, and conducting thorough quality inspections to ensure the steel meets all required standards.

What’s the Difference between 18/10, 18/8, and 18/0 Stainless Steel?

The primary differences between 18/10, 18/8, and 18/0 stainless steel lie in their composition, particularly the nickel content, which affects their properties and uses. Here’s a detailed comparison:

Composition

- 18/10 Stainless Steel: Composed of 18% chromium and 10% nickel. The high nickel content ensures exceptional corrosion-resistant, strength-enhancing, and polished-looking properties.

- 18/8 Stainless Steel: Contains 18% chromium and 8% nickel. It offers good corrosion resistance and durability but slightly less than 18/10 due to the lower nickel content.

- 18/0 Stainless Steel: Includes 18% chromium and no nickel. It provides basic corrosion resistance but lacks the added benefits of nickel, making it less durable and shiny compared to the other grades.

Corrosion Resistance

- 18/10: Excellent corrosion resistance, suitable for high-end kitchenware and cutlery that frequently come into contact with food and moisture.

- 18/8: Very good corrosion resistance, ideal for general kitchenware and household items.

- 18/0: Moderate corrosion resistance, best for items that don’t require heavy use or exposure to harsh environments.

Durability and Strength

- 18/10: High durability and strength, capable of withstanding heavy use without bending or breaking.

- 18/8: Good durability and strength, suitable for everyday use.

- 18/0: Lower durability and strength, more prone to bending and breaking under stress.

Aesthetic Appeal

- 18/10: High aesthetic appeal with a shiny, polished finish, making it a popular choice for upscale kitchenware and cutlery.

- 18/8: Also has a polished appearance, though slightly less shiny than 18/10.

- 18/0: Less shiny and may have a more matte finish, often used for budget-friendly items.

Non-reactive Surface

- 18/10: Non-reactive with acidic and alkaline foods, ensuring the taste and quality of food remain unchanged.

- 18/8: Also non-reactive, suitable for most food-related applications.

- 18/0: May react slightly with certain foods, affecting taste and quality over time.

Cost

- 18/10: Generally the most expensive due to the higher nickel content and superior properties.

- 18/8: Moderately priced, offering a good balance of cost and performance.

- 18/0: The most affordable option, suitable for budget-conscious consumers.

Common Uses

- 18/10: High-end kitchenware, cutlery, medical instruments, and decorative items.

- 18/8: General kitchenware, household items, and some industrial applications.

- 18/0: Budget-friendly kitchenware, flatware, and items with less exposure to harsh conditions.

The following table can help you see the differences between these three grades more intuitively.

| Property | 18/10 Stainless Steel | 18/8 Stainless Steel | 18/0 Stainless Steel |

| Composition | 18% Chromium, 10% Nickel | 18% Chromium, 8% Nickel | 18% Chromium, 0% Nickel |

| Corrosion Resistance | Excellent | Very Good | Moderate |

| Durability and Strength | High | Good | Lower |

| Aesthetic Appeal | Shiny, Polished Finish | Polished Appearance | Less Shiny, More Matte Finish |

| Non-reactive Surface | Non-reactive with foods | Non-reactive with most foods | May react with certain foods |

| Cost | Most Expensive | Moderately Priced | Most Affordable |

| Common Uses | High-end kitchenware, cutlery, medical instruments, decorative items | General kitchenware, household items | Budget-friendly kitchenware, flatware |

FAQs

Why is 18/10 used for stainless cookware?

Having excellent corrosion resistance, durability, and shiny appearance, 18/10 stainless steel is used for cookware The 18% chromium provides a protective layer against rust, while the 10% nickel adds strength and toughness, making it ideal for daily use in the kitchen.

Does 18/10 flatware rust?

18/10 flatware is highly resistant to rust due to its high chromium content. However, if exposed to harsh conditions or not cared for properly, it can develop minor rust spots over time. Regular cleaning and drying can help maintain its rust-free condition.

Related Reading

Will Stainless Steel Rust and How Can You Solve It?

How to Clean and Polish Stainless Steel?

Does 18/10 Stainless Steel Leach Into Food?

18/10 stainless steel is non-reactive and does not leach into food, making it a safe choice for cooking and serving. Its composition prevents reactions with acids or alkalis, maintaining the taste and quality of your meals.

Can 18/10 stainless steel be recycled?

Yes, 18/10 stainless steel is fully recyclable. Its composition allows it to be melted and reused without losing its properties, making it an environmentally friendly option for various uses. Recycling stainless steel helps conserve resources and reduce environmental impact.

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons