Contents

434 Stainless Steel Properties, Fabrication, Pros and Cons, Shapes, Application

- John

434 stainless steel is a versatile ferritic material known for its high corrosion resistance, heat tolerance, and moderate strength, making it ideal for use in harsh environments. Its performance is excellent, particularly in resisting the effects of de-icing chemicals. But how does it measure up against other types of stainless steel?

In this article, we’ll explore the properties, fabrication methods, advantages, applications of 434 stainless steel and compare it to 316 and 430 stainless steel. By the conclusion, you’ll gain a thorough insight into whether 434 is the suitable material for your particular requirements.

What is 434 Stainless Steel

434 stainless steel is a ferritic, non-hardenable steel with 83% iron, 16-18% chromium, and 1% molybdenum for improved corrosion resistance in chloride environments. It withstands up to 815°C and conforms to ASTM A240. It has a magnetic BCC crystal structure. Its resistance to oxidation and stress corrosion makes it ideal for automotive and kitchen uses, noted for its toughness in demanding conditions.

Properties of 434 Stainless Steel

434 stainless steel is a ferritic, non-hardenable material known for its excellent corrosion resistance, good heat tolerance, and moderate strength. Its physical, chemical, and mechanical properties make it suitable for applications in harsh environments, particularly where resistance to oxidation and stress corrosion is required.

Chemical Composition of 434

The chemical makeup of 434 stainless steel plays a crucial role in defining its unique properties. The main alloying elements include iron, chromium, and molybdenum, each contributing to its enhanced durability and corrosion resistance.

Molybdenum is the main difference between 434 and 430 stainless steel. It improves corrosion resistance, especially in environments exposed to chlorides and de-icing chemicals. Adding silicon improves the oxidation resistance of 434 stainless steel, which helps in high-temperature applications.

| Element | Iron (Fe) | Chromium (Cr) | Molybdenum (Mo) | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) |

| Range | Balance | 16.0-18.0% | 0.75-1.25% | ≤0.12% | ≤1.00% | ≤1.00% | ≤0.040% | ≤0.030% |

Mechanical Properties of 434

434 stainless steel offers medium strength, good ductility, and excellent resistance to wear and stress corrosion. These physical characteristics make it ideal for a range of challenging uses.

| Properties | Metric Unit | Imperial Unit |

| Tensile Strength | 415-585 MPa | 60-85 ksi |

| Yield Strength | 275 MPa | 40 ksi |

| Vickers Hardness | 160-200 HV | 160-200 HV |

| Brinell Hardness | 150-190 HB | 150-190 HB |

| Rockwell Hardness | B75-B95 | B75-B95 |

| Elongation | 20-30% | 20-30% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

(These values apply to 434 stainless steel in the annealed condition, but actual values may vary depending on processing and heat treatment.)

Physical Properties of 434

The standout feature of 434 stainless steel in terms of physical properties is its high resistance to oxidation and its ability to maintain strength and stability at elevated temperatures. For specific physical property values, please refer to the table below.

| Property | Metric Unit | Imperial Unit |

| Density | 7.75 g/cm³ | 0.280 lb/in³ |

| Melting Point | 1,480-1,530°C | 2,700-2,785°F |

| Thermal Conductivity | 25 W/m·K | 173 BTU·in/ft²·h·°F |

| Electrical Resistivity | 0.60 µΩ·m | 0.60 µΩ·m |

| Specific Heat Capacity | 460 J/kg·K | 0.11 BTU/lb·°F |

| Thermal Expansion Coefficient | 10.4 µm/m·°C | 5.8 µin/in·°F |

| Magnetic Properties | Ferritic, magnetic | Ferritic, magnetic |

Equivalent Grade of SS 434

434 stainless steel has equivalent grades across different international standards, ensuring its widespread use in various regions and industries. Below is a table listing its equivalent grades under EN, JIS, GB, and ASTM standards.

| Country | Standard | Equivalent Grade |

| Europe | EN | 1.4113 |

| Japan | JIS | SUS 434 |

| China | GB | 10Cr17Mo |

| USA | ASTM | AISI 434 |

Fabrication of SS 434

The fabrication of 434 stainless steel involves several key steps:

- Material Preparation: Cleaning and inspection to remove contaminants and surface defects.

- Forming and Shaping:

- Cold Working: Processes like bending or rolling, followed by annealing if necessary to reduce brittleness.

- Hot Working: Performed between 760°C and 980°C, followed by air cooling.

- Cutting and Machining: Processing is carried out at reduced speeds because of the material’s toughness.

- Heat Treatment: Softening or tension relief is applied to regain flexibility and reduce internal strains.

- Forging: The alloy can be forged between 2000 – 2100°F (1094 – 1149°C) after soaking thoroughly. Forging at these temperatures helps to maintain the mechanical properties and prevent unnecessary grain growth, which could weaken the material.

- Welding: Requires careful control of heat to avoid grain growth and cracking, with low heat input and possible pre/post-weld treatments.

This process ensures 434 retains its strength and corrosion resistance during fabrication.

Heat Treatment of SS 434

434 stainless steel undergoes several heat treatment steps to improve its mechanical properties and maintain performance in demanding applications:

Annealing

- Temperature: Annealing is done between 760°C and 815°C (1400°F to 1500°F).

- Process: After heating to the specified temperature, the steel is air-cooled. This softens the material, relieves internal stresses, and restores ductility lost during cold working.

Stress Relief

- Temperature: Stress relief is performed at around 650°C (1200°F).

- Process: After heating, the steel is cooled slowly to reduce internal stresses, minimizing the risk of cracking or deformation during later use.

Tempering (if applicable)

- Temperature: Tempering, when used, is typically done at lower temperatures than annealing.

- Process: This is less common for 434 stainless steel, but when applied, it further relieves stresses from welding or hot working without affecting the material’s overall strength. After tempering, the hardness may decrease to HRC 25 to HRC 35.

Avoid Hardening

- Temperature: Not applicable for hardening.

- Process: Due to its ferritic structure, 434 stainless steel cannot be hardened through heat treatment. Instead, strength and durability are improved through cold working or alloy composition adjustments.

This structured heat treatment process ensures that 434 stainless steel maintains its optimal mechanical properties and corrosion resistance.

Surface Treatment of 434 Stainless Steel

434 stainless steel may have surface imperfections upon production, so proper surface treatments are often necessary to ensure optimal performance and durability during use.

- Passivation: Removes surface contaminants and enhances corrosion resistance by forming a protective oxide layer, crucial for environments prone to corrosion.

- Polishing: Improves surface smoothness and appearance while reducing the risk of contamination buildup, ideal for kitchen and marine applications.

- Electroplating: Coats the steel with metals like nickel or chromium, boosting corrosion resistance and wear protection, extending the lifespan in harsh environments.

- Pickling: Removes scale and impurities after hot working or welding, restoring the steel’s clean surface and improving its overall resistance to corrosion.

- Sandblasting: Uses abrasive particles to clean and smooth the surface, providing a uniform finish and enhancing surface adhesion for coatings.

- Bright Annealed (BA): A reflective, smooth finish from controlled atmosphere annealing, enhancing corrosion resistance and used in aesthetic applications like kitchen and architectural elements.

- 2D and 2B Finishes: A dull finish for deep drawing and applications where lubrication retention is necessary.

These treatments improve corrosion resistance, durability and surface appearance. In addition, SteelPRO Group can provide you with more customised surface treatment options.

Common Forms and Shapes of 434 Stainless Steel

At SteelPro Group, we offer a wide range of shapes and forms of 434 stainless steel to meet various industrial and commercial needs. Below is a breakdown of the shapes and forms available through our product lines.

Plate and Sheet

Shape: Plates, sheets.

Form: Hot-rolled plates, cold-rolled sheets, polished sheets, mill-finished plates, annealed sheets.

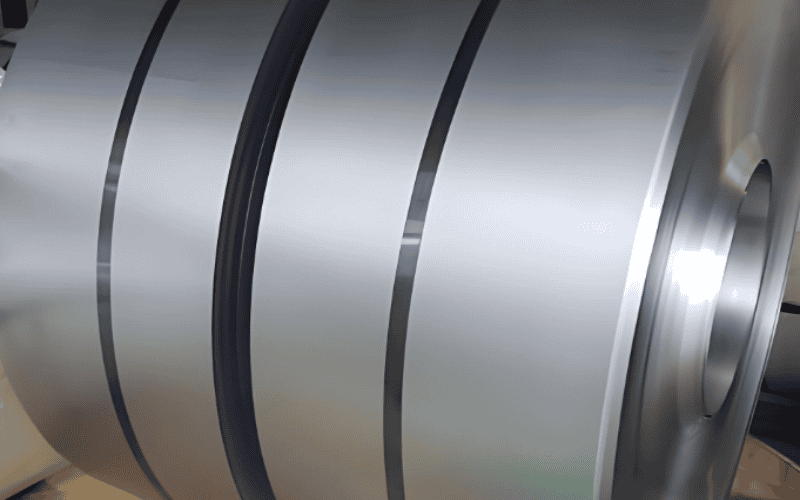

Coil

Shape: Wide coil, slit coil.

Form: Cold-rolled coil, hot-rolled coil, annealed coil, tempered coil, pickled coil.

Pipe and Fittings

Shape: Seamless pipe, welded pipe, fittings (elbows, tees, reducers).

Form: Polished pipe, pickled pipe, annealed fittings, welded fittings, threaded fittings.

Channels

Shape: U-channels, C-channels, lipped channels, slotted channels.

Form: Hot-rolled channels, cold-formed channels, galvanized channels, laser-cut channels, precision-formed channels.

Angle

Shape: Equal angles, unequal angles.

Form: Hot-rolled angles, cold-formed angles, galvanized angles, pickled angles, mill-finished angles.

Beams

Shape: I-beams, H-beams, wide flange beams.

Form: Hot-rolled beams, welded beams, laser-cut beams, galvanized beams, mill-finished beams.

Wire

Shape: Round wire, flat wire, coiled wire.

Form: Annealed wire, tempered wire, cold-drawn wire, pickled wire, galvanized wire.

Bar

Shape: Round bars, square bars, flat bars, hexagonal bars.

Form: Polished bars, pickled bars, annealed bars, cold-drawn bars, precision-cut bars.

Custom Profiles

Shape: Custom-extruded profiles, precision-cut profiles.

Form: Extruded profiles, rolled profiles, stamped profiles.

SteelPro Group ensures that our products meet the highest standards of quality and customization, providing the most suitable shapes and forms for your specific applications.

Pros and Cons of 434 Stainless Steel

434 Stainless Steel is extremely advantageous in environments where corrosion resistance and moderate strength are required. We have listed several benefits of choosing it for you. Nevertheless, similar to all substances, it has certain drawbacks.

Pros of 434 Stainless Steel:

- Superior Corrosion Resistance: Thanks to the addition of molybdenum, 434 stainless steel provides excellent resistance to corrosion, particularly in chloride environments, making it ideal for coastal, marine, or chemical applications.

- High-Temperature Performance: 434 can withstand high temperatures up to 815°C, offering stability and strength in heat-intensive environments, such as automotive exhaust systems.

- Good Weldability: Although not as easily welded as austenitic grades like 304, 434 stainless steel can still be welded with proper pre- and post-weld treatments, making it suitable for structural projects.

- Cost Efficiency: Compared to austenitic grades like 316, 434 is a more cost-effective option due to its lower nickel content, offering a good balance between performance and price.

- Lower Thermal Expansion: 434 stainless steel has lower thermal expansion than austenitic grades, reducing the risk of distortion in high-temperature applications.

- Magnetic Properties: As a ferritic stainless steel, 434 is magnetic. During cold working, its magnetism may increase due to structural changes, leading to more martensitic phase formation.

Cons of 434 Stainless Steel:

- Limited Ductility: As a ferritic grade, 434 stainless steel has lower ductility compared to austenitic stainless steels, which may limit its use in applications that require extensive forming or stretching.

- Lower Toughness: At sub-zero temperatures, 434 is more prone to brittleness compared to other stainless steels like 304 or 316, making it less suitable for cryogenic applications.

- Non-Hardenable by Heat Treatment: Unlike martensitic stainless steels, 434 cannot be hardened through heat treatment, limiting its strength enhancement options to cold working.

- More Challenging to Weld: Although weldable, 434 stainless steel requires more precise control during the welding process due to its susceptibility to grain growth, which can lead to cracking or reduced strength in the heat-affected zone.

Despite these cons, 434 stainless steel remains a strong candidate for many applications, especially where corrosion resistance, cost efficiency, and heat tolerance are primary concerns.

434 vs 316 Stainless Steel

316 stainless steel belongs to the austenitic class of stainless steels, renowned for its exceptional corrosion resistance, particularly in marine settings and highly aggressive environments.

- Corrosion Resistance: Its enhanced corrosion resistance stems from a higher concentration of nickel and molybdenum, enabling it to outperform 434 stainless steel in challenging conditions. However, 434 is more than adequate for less demanding environments.

- Magnetic Properties: 434 is magnetic, whereas 316 is non-magnetic. This makes 434 more suitable for applications requiring magnetic properties.

- Cost: 316 has a higher nickel content and is therefore generally more expensive than 434.

- Strength and Toughness: 316 offers better toughness and resistance to pitting, especially in chloride-rich environments, whereas 434 is less suited to marine applications.

434 vs 430 Stainless Steel

While both 434 and 430 stainless steel are ferritic stainless steel, 434 offers better corrosion resistance due to the addition of molybdenum.

- Corrosion Resistance: 434 performs better than 430 in environments exposed to chlorides or deicing salts.

- Cost: 430 is less expensive than 434 and is suitable for applications where cost is the primary consideration and corrosion resistance is less demanding.

- Applications: Both are used in similar industries, but 434 is often chosen for more demanding outdoor environments or where higher corrosion resistance is needed.

Application for 434 Stainless Steel

434 stainless steel is extensively utilized in numerous sectors because of its resistance to corrosion, ability to withstand heat, and balanced strength. Below are key sectors where 434 stainless steel is commonly applied, along with specific uses and reasons for its suitability.

Automotive Industry

Applications:

- Exhaust systems

- Heat shields

- Catalytic converters

Reason: 434 stainless steel’s excellent resistance to oxidation at high temperatures and its cost-efficiency make it ideal for automotive parts exposed to heat and corrosive gases.

Kitchen Equipment

Applications:

- Sinks

- Cookware

- Kitchen countertops

Reason: Its corrosion resistance, especially in moist and acidic environments, along with ease of cleaning, makes 434 perfect for food-grade kitchen equipment.

Construction and Architecture

Applications:

- Structural supports

- Exterior cladding

- Roofing materials

Reason: 434’s good corrosion resistance in outdoor conditions and relatively low thermal expansion make it suitable for structural and architectural components.

Chemical Processing

Applications:

- Chemical tanks

- Heat exchangers

- Piping systems

Reason: 434 stainless steel resists corrosion from chloride-rich environments, making it a suitable material for chemical processing equipment exposed to harsh chemicals.

Marine Applications

Applications:

- Boat fittings

- Dock components

- Coastal infrastructure

Reason: The addition of molybdenum enhances its resistance to pitting and crevice corrosion, making 434 stainless steel ideal for marine environments where saltwater exposure is common.

Household Appliances

Applications:

- Washing machine drums

- Dryer components

- Refrigerator panels

Reason: 434 stainless steel’s durability, corrosion resistance, and attractive finish make it a popular choice for appliance components that are exposed to moisture and frequent use.

Industrial Equipment

Applications:

- Heat exchangers

- Furnace parts

- Fasteners

Reason: Its heat resistance and ability to withstand moderate mechanical stress make 434 stainless steel well-suited for industrial environments where high temperatures and corrosive materials are involved.

In each of these sectors, 434 stainless steel offers a balance of cost, performance, and durability, making it a versatile choice for a wide range of applications.

What is Equivalent to 434 Material?

434 stainless steel has several equivalents across different standards, such as EN 1.4113, JIS SUS 434, GB 10Cr17Mo, and ASTM AISI 434. These types have comparable chemical makeups and physical characteristics, allowing them to be used interchangeably in various uses.

How Does 434 Stainless Steel Compare to 304 Stainless Steel in Corrosion Resistance?

434 stainless steel offers better resistance to chloride-induced corrosion due to the presence of molybdenum, while 304 stainless steel has superior general corrosion resistance but may be less resistant in environments with chlorides or high salinity.

Is 434 Stainless Steel Suitable for High-Temperature Environments?

Yes, 434 stainless steel performs well in high-temperature environments, withstanding temperatures up to 815°C. It retains its durability and resistance to oxidation, making it appropriate for uses that involve exposure to high temperatures.

What Makes 434 Stainless Steel Different From Other Ferritic Stainless Steels?

434 stainless steel stands out from other ferritic stainless steels due to its enhanced corrosion resistance provided by added molybdenum, along with its improved resistance to stress corrosion cracking compared to other ferritic grades.

Can 434 Stainless Steel be Welded Easily?

434 stainless steel can be welded, but it requires care, as ferritic steels can be prone to grain growth and brittleness in the heat-affected zone. Before and after welding, treatments might be required to prevent fractures and guarantee a solid weld.

434 Stainless Steel Manufacturer

As a specialized stainless steel manufacturer, SteelPro Group is committed to delivering the highest quality products with 100% quality assurance and a lifetime warranty. Our standing is founded on dependability, accuracy, and client satisfaction, positioning us as a reliable partner for businesses globally.

By choosing our 434 stainless steel, you benefit from:

- High Quality: Our 434 stainless steel undergoes strict quality checks to ensure durability and top performance in demanding conditions.

- Tailored Solutions: We offer personalized shapes and formats to match your specific project needs with accuracy.

- Affordable Pricing: We provide budget-friendly options without compromising standards, allowing you to remain on budget.

- Technical Support: Our expert engineers are ready to assist with advice and support throughout your purchase and application.

- Quick Delivery: Through an international distribution network, we ensure prompt and dependable delivery to keep your projects on schedule.

Contact us today to submit your project requirements and experience our 434 stainless steel solutions and customized services!

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons