Contents

Precipitation Hardening Stainless Steel: Definition, Composition, Properties, Applications, Grades, and More

- John

Precipitation hardening stainless steel significantly improves its mechanical strength and durability through unique heat treatment technology, making it the material of choice in many fields such as aerospace, automotive manufacturing, oil and gas, etc. So, what exactly is precipitation hardening stainless steel?

In this article, we will introduce you to everything about precipitation hardening stainless steel in detail, such as its definition, composition, properties, applications, common grades, processing, and welding techniques of this high-performance material.

What is Precipitation Hardening Stainless Steel?

Precipitation hardening stainless steel (PH stainless steel) is a type of stainless steel that achieves high strength and excellent corrosion resistance through heat treatment technology. It is divided into martensitic, semi-austenitic and austenitic types. It belongs to the Fe-Cr-Ni alloy series and is added with copper, molybdenum, niobium, titanium and aluminum.

Types of Precipitation Hardening Stainless Steels

PH stainless steels are categorized into three types based on their matrix structure after heat treatment: martensitic, semi-austenitic, and austenitic.

Martensitic PH Stainless Steel

Like 17-4 PH, they start out with an austenitic structure at annealing temperatures (1040–1065°C) and transform to martensite upon cooling. Aging at 482–593°C increases their strength to 1170–1376 MPa. These steels are used in high-strength applications such as aerospace and valves, but have low ductility, making cold forming difficult.

Semi-Austenitic PH Stainless Steel

Retain their austenitic structure after solution heat treatment and are more ductile, making them ideal for forming. To harden, the austenite is first transformed to martensite and then aged at 455–593°C. They are often found in sheet form, such as 17-7 PH, for springs and fasteners where formability and strength are required.

Austenitic PH Stainless Steel

Like A286, they retain their non-magnetic austenitic structure after heat treatment. Aging at 650-760°C increases hardness and strength. Although their mechanical properties are lower than the other two types, they have good toughness and are ideal for high-temperature applications such as jet engine and turbine blades.

Chemical Composition of Precipitation Hardening Stainless Steel

The chemical composition of PH stainless steel typically includes iron, chromium, and nickel, with the addition of small amounts of copper, titanium, aluminum, molybdenum, niobium, and other elements to achieve the precipitation hardening effect. These alloying elements, combined with specific ratios and heat treatment processes, help form hardening phases at different temperatures, thus enhancing the material’s strength and corrosion resistance.

For your reference, we have listed the typical chemical compositions of three PH stainless steels in the table below.

| C | Cr | Ni | Cu | Al | Mo | Ti | Mn | Si | P | S | V | ||

| 17-4 PH (%) | Martensitic | ≤ 0.07 | 15.0-17.5 | 3.0-5.0 | 3.0-5.0 | – | ≤ 0.5 | – | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | ≤ 0.03 | – |

| 17-7 PH (%) | Semi-Austenitic | ≤ 0.09 | 16.0-18.0 | 6.5-7.75 | – | 0.75-1.5 | – | – | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | ≤ 0.03 | – |

| A2869 (%) | Austenitic | ≤ 0.08 | 14.0-16.0 | 24.0-27.0 | ≤ 0.35 | – | 1.0-1.5 | 1.9-2.3 | ≤ 2.0 | ≤ 1.0 | ≤ 0.03 | ≤ 0.025 | 0.10-0.50 |

Properties of Precipitation Hardening Stainless Steel

The following characteristics are key to understanding the performance of precipitation hardening stainless steels.

- High Strength: Precipitation hardening stainless steels exhibit high tensile and yield strengths, making them suitable for high-load applications.

- Corrosion Resistance: These steels provide good resistance to corrosion in various environments, particularly when combined with elements like chromium and nickel.

- Hardness: Aging processes significantly increase hardness, making these steels ideal for wear-resistant applications.

Physical Properties

| Physical Property | Specific Values | Description |

| Density | 7.7-8.0 g/cm³ | Provides good structural stability and strength. |

| Thermal Conductivity | 15-20 W/m·K | Suitable for heat exchange applications. |

| Thermal Expansion | 10-12 µm/m·K | Low expansion, reducing distortion under temperature changes. |

| Melting Point | 1400-1450°C | Ensures durability at high temperatures. |

| Magnetic Properties | Varies (depends on type) | Martensitic and semi-austenitic types are often magnetic. |

| Electrical Resistivity | Moderate | Suitable for applications where conductivity is not critical. |

Mechanical Properties

| Mechanical Property | Specific Values | Description |

| Tensile Strength | 850-1700 MPa | Provides high load-bearing capacity. |

| Yield Strength | 800-1500 MPa | High resistance to permanent deformation. |

| Elongation | 10-20% | Can stretch before breaking, indicating ductility. |

| Hardness | 35-47 HRC | Very high hardness after aging, ideal for wear-resistant parts. |

| Modulus of Elasticity | 190-210 GPa | Resistance to elastic deformation, offering stiffness. |

| Fatigue Resistance | Moderate | Good resistance to cyclic loading and fatigue failure. |

| Impact Resistance | Moderate-High | Able to absorb energy and resist impact damage. |

| Toughness | Moderate | Ability to deform without breaking under sudden force. |

| Weldability | Good | Can be welded, but post-weld heat treatment may be required. |

| Formability | Moderate-High | Can be formed into complex shapes, particularly in semi-austenitic types. |

Chemical Properties

| Chemical Property | Performance | Description |

| Corrosion Resistance | Moderate-High | Good corrosion resistance in a variety of environments. |

| Oxidation Resistance | High | Strong resistance to oxidation at elevated temperatures. |

| Chemical Stability | High | Stable under various chemical exposures, ideal for harsh environments. |

| Resistance to Stress Corrosion Cracking (SCC) | Moderate-High | Better than austenitic steels, especially in chloride environments. |

Precipitation Hardening Stainless Steel Grades

PH stainless steel comes in various grades, each with unique properties and application fields. Below are some common PH stainless steel grades and their features and applications.

| Grade | Type | Features | Applications |

| 17-4 PH | Martensitic | High strength, moderate corrosion resistance, easy to machine | Aerospace parts, valves, gears, shafts, pumps, high-strength uses |

| 15-5 PH | Martensitic | High strength, good toughness, excellent corrosion resistance | Aerospace, chemical processing, precision machinery, nuclear industry |

| PH 13-8 Mo | Martensitic | High strength, superior toughness, excellent stress corrosion resistance | Aerospace structures, oil and gas equipment, turbine components |

| 13-8 PH | Martensitic | High strength, good toughness, good corrosion resistance | Aerospace, petrochemical, medical devices for high-strength applications |

| 17-7 PH | Semi-Austenitic | Excellent formability, high strength after aging, good corrosion resistance | Springs, fasteners, aircraft parts requiring strength and formability |

| AM 350 | Semi-Austenitic | Good formability, high strength, good corrosion resistance | Turbine blades, springs, fasteners, high-strength, corrosion-resistant parts |

| AM 355 | Semi-Austenitic | Good strength, formability, and corrosion resistance | Aerospace parts, tools, cutting equipment with good formability and strength |

| PH 15-7 Mo | Semi-Austenitic | Good formability, high strength, good fatigue and corrosion resistance | Springs, pressure vessels, aircraft parts needing strength, corrosion resistance, and formability |

| XM-16 | Semi-Austenitic | Good strength, ductility, formability, and corrosion resistance | Medical devices, aerospace components with good formability and strength |

| A286 | Austenitic | Good high-temperature strength, excellent creep resistance, non-magnetic | High-temperature applications like jet engine components, turbine blades |

| 17-10 P | Austenitic | Retains austenitic structure, non-magnetic, excellent high-temperature performance | High-temperature, corrosion-resistant uses like chemical equipment and heat exchangers |

| 17-10 Mo | Austenitic | Excellent corrosion resistance, non-magnetic, high-temperature strength | Chemical processing equipment, high-temperature machinery |

What is 15-5 precipitation hardening stainless steel?

15-5 PH is a martensitic precipitation hardening stainless steel, a tough, high-strength, corrosion-resistant stainless steel alloy. The name “15-5” refers to its composition: approximately 15% chromium and 5% nickel. Used in aerospace parts, chemical processing equipment, shafts and gears, etc.

What is 17-4 precipitation hardened stainless steel?

17-4 PH is a martensitic precipitation-hardening stainless steel with high strength and excellent corrosion resistance. The name “17-4” refers to its composition: approximately 17% chromium and 4% nickel, with copper and niobium/aluminum added for increased strength and hardness. 17-4 PH is widely used in aerospace components, chemical and petrochemical equipment, medical equipment, etc.

Precipitation Hardening Stainless Steel Forms

Precipitation hardening stainless steel is available in various forms to suit a wide range of industrial applications. Common forms include:

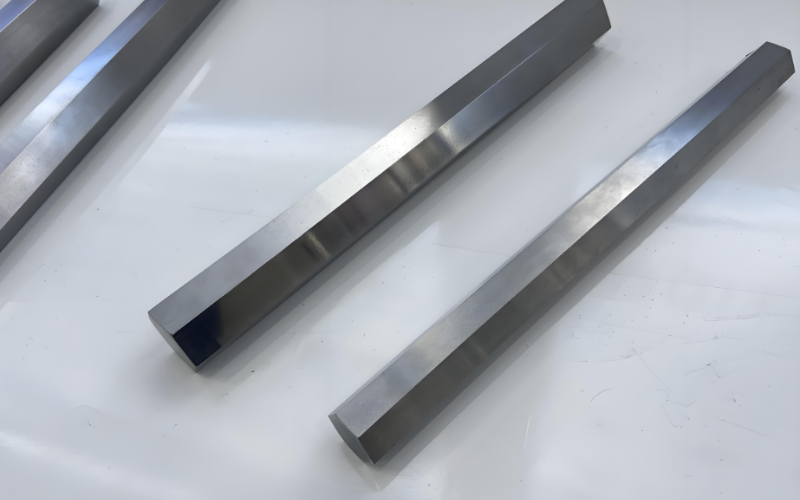

- Precipitation hardening stainless steels sheets and plates: Used in aerospace, automotive, and industrial equipment due to their high strength and corrosion resistance.

- Precipitation hardening stainless steels rods and bars: Employed in manufacturing precision components such as shafts, gears, and fasteners that require durability and hardness.

- Precipitation hardening stainless steels tubes and Pipes: Frequently used in chemical, petrochemical, and oil & gas industries where strength and corrosion resistance are critical for fluid transport systems.

- Precipitation hardening stainless steels wire: Common in medical devices, springs, and fasteners where high strength and flexibility are needed.

- Precipitation hardening stainless steels forgings: Used in heavy-duty applications like turbine blades and structural components due to their ability to withstand high stress and temperatures.

These forms allow precipitation hardening stainless steels to be used in demanding environments where both high strength and corrosion resistance are essential.

Pros and Cons of Precipitation Hardening Stainless Steel

Advantages

- High Strength: After precipitation hardening, the material’s strength is significantly enhanced, with tensile strength reaching 850-1700 MPa.

- Good Corrosion Resistance: PH stainless steel exhibits better corrosion resistance compared to traditional martensitic stainless steel, making it suitable for harsh environments.

- Good Processability: In the solution-treated condition, the material is relatively soft, making it easy to process and shape.

- Weldability: With proper welding and heat treatment, PH stainless steel can achieve excellent weld quality.

Disadvantages

- Complex Heat Treatment: The precipitation hardening process involves multiple heat treatment steps, making the process more complex and costly.

- Limited High-Temperature Resistance: PH stainless steel excels at moderate temperatures, but extended exposure to high heat can degrade its performance.

- Magnetic Limitations: Certain PH stainless steels can develop slight magnetism in specific conditions, restricting their suitability for some applications.

What is Precipitation Hardening Stainless Steel Used for?

Precipitation hardening stainless steel is used in applications that require a combination of high strength, toughness, and corrosion resistance. Common uses include:

- Aerospace Components: Used for high-strength parts such as turbine blades, gears, and structural components due to its ability to retain strength at high temperatures.

- Medical Devices: Employed in surgical instruments, orthopedic implants, and dental tools because of its biocompatibility and durability.

- Oil & Gas Industry: Used for valves, pump shafts, and fittings where both corrosion resistance and mechanical strength are critical in harsh environments.

- Chemical Processing Equipment: Suitable for vessels, reactors, and piping systems due to its excellent corrosion resistance and toughness.

- Nuclear Power: Utilized in high-stress components, such as reactor internals and fasteners, due to its resistance to radiation and long-term durability.

- Marine Applications: Found in propeller shafts, pumps, and hardware, where resistance to corrosion and seawater is essential.

Welding of Precipitation Hardening Stainless Steel

PH stainless steel has good weldability, especially in the solution-treated condition. Common welding methods, such as TIG and MIG, can be used, but care must be taken to avoid softening in the heat-affected zone. For thicker materials, post-weld aging treatment is often recommended to restore the strength of the weld area.

When welding PH stainless steel, it is best to use filler materials that match the parent metal. For example, ER630 wire can be used when welding 17-4 PH. Additionally, maintaining low heat input and minimizing the size of the heat-affected zone are crucial for ensuring weld quality.

Difference Between Martensitic and Precipitation Hardening Stainless Steel

The primary distinction between martensitic stainless steel and PH stainless steel resides in their distinct strengthening methodologies and consequential performance attributes.

Strengthening Mechanism: In terms of strengthening mechanisms, martensitic stainless steel achieves its enhanced strength through a combination of quenching and tempering processes. Conversely, PH stainless steel derives its strength from the formation of metallic precipitates within its microstructure, a process known as precipitation hardening.

Performance: PH stainless steel generally has higher strength and better corrosion resistance but lower high-temperature performance compared to martensitic stainless steel.

Learn about other types of stainless steel: austenitic, ferritic, and duplex.

Is Precipitation Hardening Stainless Steel Magnetic?

The magnetic properties of PH stainless steel depend on its alloy composition and heat treatment process. Most martensitic PH stainless steels exhibit some level of magnetism after solution treatment, while austenitic and semi-austenitic PH stainless steels generally remain non-magnetic under most conditions. When making material selection decisions, it is imperative to take into account the specific demands of the application as well as the associated processing conditions.

Related Reading

Is Stainless Steel Magnetic?

What is Precipitation Hardening?

Precipitation hardening, or age hardening, is a heat treatment process used to enhance yield strength. In PH stainless steel, this process involves three key steps: solution treatment, quenching, and aging.

- Solution Treatment: During the initial stages of solution treatment, the material is typically heated in a temperature range of 1040°C to 1065°C. This high temperature facilitates the dissolution of alloying elements, resulting in the formation of a homogeneous solid solution.

- Quenching: After solution treatment, the material is rapidly cooled to retain solute elements in a supersaturated state, preventing the formation of precipitates. Common quenching media include air and water.

- Aging: The material is reheated to a lower temperature (e.g., 480 to 620°C) and held for several hours to allow fine precipitates to form, enhancing the material’s strength and hardness.

What Is the Difference between Tempering and Precipitation Hardening?

Tempering and precipitation hardening are both heat treatment processes, but they differ in purpose, method, and the materials they are typically applied to.

Purpose: Tempering is performed after hardening (quenching) to reduce the brittleness of the hardened steel while retaining some of its hardness to make the material tougher and less prone to cracking. Precipitation hardening increases strength and hardness by forming tiny particles (called precipitates) in the metal’s structure.

Material: Tempering is used for martensitic steels in stainless steel. Precipitation hardening is used for precipitation hardened stainless steel.

Process: During tempering, the material is quenched and then reheated to a lower temperature (150-650°C). The temperature and duration of tempering control the degree to which hardness is reduced and toughness is increased. Precipitation hardening involves two stages – solution treatment (heating and quenching) and aging (reheating to a moderate temperature, usually 480-620°C). During aging, fine precipitates are formed, which increase hardness and strength.

Application: Tempering is used for tools, knives, and other items that require high hardness but must minimize brittleness. Precipitation hardening is common in aerospace, automotive and industrial components where strength and corrosion resistance are critical.

Age Hardening vs Precipitation Hardening

Age Hardening and Precipitation Hardening are heat treatment processes used to enhance the strength and hardness of alloys.

Age Hardening

- Definition: A general process that increases strength through precipitate formation.

- Steps: Involves solution treatment, quenching, and aging.

- Applications: Commonly used for aluminum, titanium, and some stainless steels.

- Mechanism: Strengthens by forming particles that hinder dislocation movement.

Precipitation Hardening

- Definition: A specific type of age hardening focusing on controlled precipitate formation.

- Steps: Similar to age hardening, but emphasizes optimizing precipitate size and distribution.

- Applications: Used in precipitation hardening stainless steels (e.g., 17-4 PH) and nickel alloys.

- Mechanism: Targets fine, evenly distributed precipitates to enhance strength and toughness.

In summary, age hardening is broader, while precipitation hardening specifically optimizes precipitate characteristics for improved performance.

Get Satisfactory Stainless Steel!

Our company specializes in producing high-precision stainless steel products to meet the diverse needs of numerous industries. If you would like to learn more about stainless steel or any other steel variant, you can browse our blog articles or contact our team of metal experts directly for personalized assistance. If you need custom precision steel and metal products, contact us for personalized service and quotes.

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons