Contents

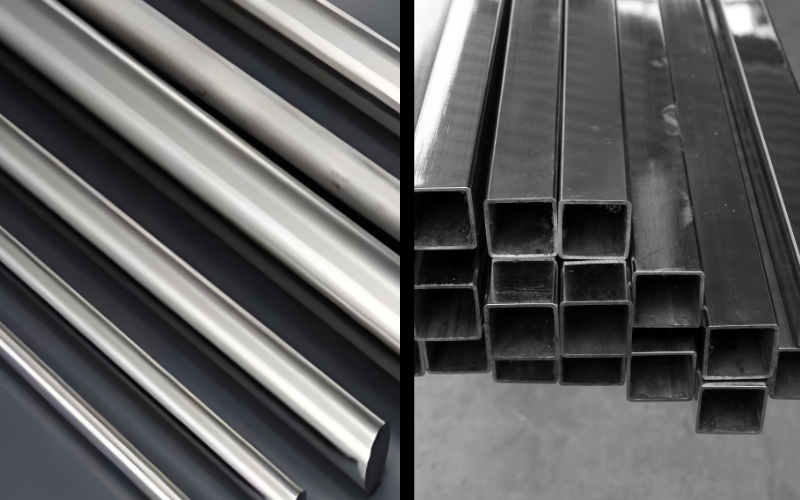

Alloy Steel vs Stainless Steel: A Head-to-Toes Comparison

- John

What Is Alloy Steel

Alloy steel is a type of steel that contains at least one alloying element besides carbon. It can be classified into low-alloy and high-alloy steel based on the amount of alloying elements. Stainless steel, for example, is a type of high-alloy steel known for its corrosion resistance due to its high chromium content.

Adding specific alloying elements often introduces new characteristics or improves certain properties. All alloy steels contain iron and carbon, with other common alloying elements like chromium, molybdenum, vanadium, and titanium, which help improve performance under specific conditions.

Types of Alloy Steel

Here are some common types of alloy steel categorized by alloying content and applications:

| Type | Description |

| Low alloy steel | Contains 1-5% alloy elements, balances strength and ductility, and is widely used in structures. |

| Medium alloy steel | Contains 5-10% alloy elements, with higher tensile strength and wear resistance and is used in the aerospace and automotive industries. |

| High alloy steel | Contains >10% elements like chromium or nickel, excellent corrosion, and heat resistance. |

| Structural steel | Used in bridges, buildings, and infrastructure, offers high load-bearing strength and toughness. |

| Tool steel | Used for cutting, drilling, shaping, high hardness, and wear resistance in demanding environments. |

| Stainless steel | Contains >10.5% chromium, highly corrosion-resistant, used in chemical, food processing, and construction. |

| Heat-resistant steel | Retains strength and oxidation resistance in high temperatures, used in furnaces, turbines, and chemical plants. |

Common Alloying Elements and Their Effects

There are many alloying elements that can be introduced to improve the properties of steel. Each has its own unique properties. Here are the five most commonly used alloying elements:

Chromium (Cr):

- At low concentrations (approximately 0.5% to 2%), chromium can increase the hardness and strength of steel.

- At high concentrations (around 12% or more), chromium significantly enhances the corrosion resistance of steel, which is a key component in stainless steel.

Manganese (Mn):

- Manganese helps improve the strength and toughness of steel, reducing brittleness, especially when sulfur and phosphorus levels are low.

- It also acts as a deoxidizer and desulfurizer, reducing the impact of harmful impurities.

Tungsten (W):

- Tungsten increases the high-temperature strength and hardness of steel, enhancing thermal stability.

- Commonly used in the production of high-speed tool steels, it improves wear resistance and red hardness (the ability to retain hardness at high temperatures).

Nickel (Ni):

- Nickel enhances the toughness and strength of steel, improving low-temperature performance.

- When the nickel content is above 8%, it significantly improves the corrosion resistance of steel (as in austenitic stainless steel).

Vanadium (V):

- Vanadium forms carbides that refine the grain structure, increasing the strength, hardness, and wear resistance of steel.

- When used in combination with chromium, it further enhances the overall properties of steel, including strength and heat resistance.

What Is Stainless Steel

SS steel is an iron alloy with at least 10.5% chromium, being highly corrosion-resistant by forming a protective chromium oxide layer on the surface. It is classified by crystal structure into types like austenitic, ferritic, martensitic, duplex, and precipitation-hardening.

Additional elements like nickel, molybdenum, and nitrogen can also be added to further enhance its corrosion resistance and mechanical properties. Stainless steel is widely used in kitchenware, medical instruments, construction, and chemical processing due to its durability and corrosion resistance.

Types of Stainless Steel

Stainless steel can be categorized into five groups by crystalline structure listed below:

| Stainless Steel Type | Description |

| Austenitic | Contains 17-25% chromium and 8-20% nickel. Non-magnetic, offers excellent corrosion resistance, toughness, and weldability. Common in food processing, chemical plants, kitchenware. Common grades: 304, 316. |

| Ferritic | Contains 11-27% chromium, little or no nickel. Magnetic, less corrosion resistant than austenitic but with better high-temperature properties. Used in automotive parts, appliances, and heat exchangers. Common grades: 430, 409. |

| Martensitic | Contains 14-18% chromium and 0.2-2% carbon. Magnetic, can be hardened by heat treatment, offering moderate corrosion resistance but reduced ductility. Common in knives, tools, and turbine blades. Common grades: 410, 416, 420. |

| Duplex | Balanced austenitic and ferritic structure, with 18-28% chromium and 3.5-5.5% nickel. Strong, highly resistant to pitting and chloride stress corrosion. Used in pipelines and chemical tanks. Common grades: 2205, 2507. |

| Precipitation-Hardening | Contains 12-16% chromium, 3-8% nickel, with other elements like copper and aluminum. Strong, ductile, and heat-treatable. Common in aerospace and industrial components. Common grades: 17-4PH, 15-5PH. |

Chromium and Its Significance to Stainless Steel

Corrosion-Resistance Mechanism: Chromium is essential for stainless steel’s corrosion resistance by forming a thin, stable oxide layer (chromium oxide) on the surface. This passive layer acts as a barrier, protecting the metal underneath from oxygen and moisture, thus preventing rust and oxidation.

Other corrosion-resistant alloying elements include:

- Nickel (Ni)

- Molybdenum (Mo)

- Nitrogen (N)

- Copper (C)

- Titanium (Ti)

Chromium is important to stainless steel because of reasons as below:

- It helps stainless steel resist rust and corrosion, being more durable in wet or humid conditions.

- It strengthens stainless steel, making it more durable and less prone to wear over time.

- It helps stainless steel withstand high temperatures, making it useful in cooking equipment and industrial applications.

- It helps stainless steel stay clean and hygienic, which is essential in medical and food industries.

- It gives stainless steel its unique shiny, polished look, making it attractive for many uses.

Property Differences Between Alloy Steel vs Stainless Steel

Strength

Let’s compare the key properties of alloy steel and stainless steel.

| Property | Description | Alloy Steel | Stainless Steel |

| Tensile Strength | Maximum stress a material can withstand before breaking; varies with composition and treatment | High; can be enhanced with alloying elements and heat treatment, but varies widely | High; generally lower, but some grades (e.g., martensitic) can be strong |

| Yield Strength | Stress at which a material begins to deform plastically; influenced by heat treatment | High; adjustable through heat treatment | Moderate; varies with grade and treatment, more plastic deformation under stress |

| Hardness | Resistance to deformation or indentation; affected by alloying and treatments | High; enhanced by alloying elements and heat treatment | Moderate; can improve with certain treatments |

| Toughness | Ability to absorb energy without fracturing; depends on composition | Good; varies with alloy and treatment | Moderate to high; austenitic grades maintain toughness at low temperatures |

| Ductility | Ability to deform under tensile stress without breaking | Moderate | High |

| Corrosion Resistance | Resistance to chemical deterioration; depends on alloying elements | Low to moderate; can be improved with chromium addition | Excellent; high chromium content provides superior resistance |

| Heat Resistance | Ability to retain properties at high temperatures; influenced by alloy composition | Good; varies with alloying elements | Excellent |

| Magnetic Properties | Response to magnetic fields; depends on microstructure | Generally magnetic | Varies; austenitic grades are non-magnetic, others are magnetic |

Processing Differences Between Alloy Steel vs Stainless Steel

Let’s discuss the key differences between alloy steel and stainless steel in terms of processing.

Welding

Welding stainless steel is more challenging, requiring stricter control and post-weld treatment, whereas welding alloy steel is relatively easier.

Check the table below for a quick comparison between the two:

| Aspect | Alloy Steel | Stainless Steel |

| Welding Difficulty | Easier to weld, especially low-carbon alloys | More challenging, prone to cracking and stress corrosion |

| Heat-Affected Zone (HAZ) | Stable, but may require post-weld heat treatment | Corrosion resistance may decrease, risk of intergranular corrosion in high-carbon grades |

| Post-Weld Treatment | May need quenching or annealing | Requires cleaning and passivation to restore corrosion resistance |

| Welding Techniques | Suitable for various methods (MIG, TIG, stick welding) | TIG commonly used; may require inert gas shielding |

| Distortion Control | Less prone to distortion, especially in carbon alloys | Higher thermal expansion, more prone to warping |

Machining

Compared to stainless steel, alloy steel is generally easier to machine. Stainless steel, due to its toughness and hardness, is more difficult to machine and requires special attention to tool selection, coolant usage, and adjustment of machining parameters.

Check the table below for a quick comparison between the two:

| Aspect | Alloy Steel | Stainless Steel |

| Hardness & Machinability | Moderate to high hardness; machinability depends on alloy composition. | Higher hardness; especially austenitic stainless steel, is tough to machine. |

| Tool Selection | Carbide or high-speed steel tools are effective; slower tool wear. | Requires harder tools like carbide with coatings (e.g., TiAlN) to resist wear. |

| Coolant Requirements | Lower coolant needed, but more cooling required for harder alloys. | Requires more coolant due to high heat generation and tool wear. |

| Cutting Speed & Feed Rate | Higher speeds and feed rates, depending on composition. | Lower speeds and feed rates to prevent tool wear and material deformation. |

| Surface Finish | Generally good surface finish. | Surface finish can be affected by work hardening and toughness. |

Hardening

Alloy steel relies on heat treatment to achieve hardening, while stainless steel (especially austenitic stainless steel) depends on cold working. Some stainless steel, such as martensitic stainless steel, can be hardened through quenching.

Check the table below for a quick comparison between the two:

| Property | Alloy Steel | Stainless Steel |

| Hardening Mechanism | Quenching and tempering. Alloying elements improve hardenability, creating martensite for hardness. | Martensitic grades: quenching for hardening.Austenitic grades: cold working (cannot harden by heat treatment).Precipitation-hardening grades: by aging. |

| Hardenability | High hardenability due to alloying elements, effective even in thick sections. | Limited hardenability. Martensitic steels harden through quenching, while austenitic steels cannot be hardened by heat treatment. |

| Hardness and Toughness | Can achieve high hardness with some toughness after quenching and tempering. | Austenitic grades have lower hardness unless cold-worked. Martensitic grades can be hardened to high levels but may lose toughness. |

Application Differences Between Alloy Steel vs Stainless Steel

Alloy steel is known for its strength, durability, and toughness, making it a go-to material in industries like construction, automotive, and aerospace. It is often used in manufacturing gears, pipes, and tools where strength is a priority, but corrosion resistance is less critical.

Stainless steel is highly valued for its corrosion resistance, which makes it ideal for industries like food processing, medical equipment, and chemical manufacturing. Common applications include kitchen utensils, medical instruments, and machinery that must withstand harsh environments or frequent cleaning.

Price and Cost Differences Between Alloy Steel vs Stainless Steel

Stainless steel is generally more expensive than alloy steel due to the higher proportion of alloying elements (e.g. chromium, nickel), more complex and strict manufacturing processes and control, and other important factors. For rough reference, alloy steel typically costs between $600 and $2,500, while stainless steel ranges from $1,800 to $4,500.

Comparing Maintenance and Care of Alloy Steel vs Stainless Steel

Take a look at how alloy steel and stainless steel differ in terms of maintenance and care.

| Aspect | Alloy Steel | Stainless Steel |

| Corrosion Resistance | Varies by alloy, generally not good as stainless steel; requires protective coatings or regular oiling to prevent rust, especially in humid environments. | High corrosion resistance due to chromium; forms a passive layer that prevents rust, even in humid conditions. |

| Cleaning | Requires more care, especially in harsh environments; after cleaning, protective oil or anti-rust agents may be needed. | Easy to clean with soap and water or specialized cleaners; periodic cleaning prevents buildup of contaminants. |

| Storage | Should be stored in dry environments, with surfaces treated to prevent rust; avoid contact with corrosive chemicals or metals. | Can be stored in more challenging environments; periodic cleaning and inspection suffice to maintain performance. |

| Maintenance Cycle | Requires more frequent inspections, especially in corrosive environments; protective coatings may need to be reapplied. | Less frequent maintenance due to natural corrosion resistance; periodic cleaning and surface inspection are sufficient. |

| Suitable Environments | Best in high-strength applications; requires extra protection in humid or corrosive environments. | Ideal for moist, corrosive environments like marine or food processing industries; requires minimal maintenance. |

Comparing Environmental Impact Between Alloy Steel and Stainless Steel

Alloy steel requires less energy to produce than stainless steel, making it more eco-friendly in terms of energy use. However, stainless steel is more durable and resistant to corrosion, which means it lasts longer and requires less frequent replacement. This durability reduces waste and the need for additional resources.

Both materials can be recycled, but stainless steel has a higher recycling rate, further reducing its environmental footprint.

Overall, alloy steel is less energy-intensive, while stainless steel’s durability and recyclability make it more sustainable in the long run.

Advantages of Alloy Steel Over Stainless Steel

- Higher tensile strength, offering better performance under stress.

- More flexible in terms of hardness and strength through heat treatment.

- Typically more affordable, making it cost-effective for large projects.

- Better suited for heavy-duty applications due to its higher wear resistance.

- Can be customized to meet specific needs by adjusting its composition.

Advantages of Stainless Steel Over Alloy Steel

- More resistant to corrosion, especially in humid or marine environments.

- Longer lifespan due to its durability and resistance to rust.

- Requires less maintenance and care over time.

- Easier to clean, making it ideal for hygienic applications.

- Better appearance, with a more polished and shiny finish.

What You Might Also Concern

Which is better for jewelry, alloy steel or stainless steel?

Stainless steel is better for jewelry because it is more resistant to corrosion and tarnishing and is hypoallergenic.

Related Reading

Will Stainless Steel Tarnish or Fade?

Which is better for knives, alloy steel or stainless steel?

The choice depends on the knife’s intended use. Stainless steel is better for knives due to its resistance to corrosion, while alloy steel may offer better edge retention and durability.

Which is better, aluminum alloy or stainless steel?

Stainless steel is stronger and more durable, while aluminum alloy is lighter and more corrosion-resistant. The choice depends on the application.

Is stainless steel pure or alloy?

Stainless steel is an alloy and also an alloy steel, which is a specific type of alloy.

Summary & Furthermore

This article mainly discusses the key differences between alloy steel and stainless steel in terms of properties, processing, applications, cost, and several other important aspects. To learn more about stainless steel or other steel types, check out our blog or contact our metal experts.

As a leading manufacturer and solutions provider of specialty steel, we deliver multi-industry application solutions and customized services with a 100% quality guarantee, committed to growing together with our customers. Visit our website to learn more, or send us a quote, and we will contact you shortly!

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons