Contents

18/8 Stainless Steel: Definition, Composition, Properties, Applications and More

- John

What Is 18/8 Stainless Steel

18/8, also called 304, is a type of austenitic stainless steel with a face-centered cubic (FCC) crystal structure, primarily composed of 18% chromium and 8% nickel. It falls under the ASTM A240 standard. Equivalent grades include SUS304 (JIS) and X5CrNi18-10 (EN).

18/8 offers excellent corrosion resistance in mildly corrosive environments with good machinability and excellent weldability. It maintains good toughness and mechanical properties at high and low temperatures, making it widely used in kitchen utensils, medical equipment, and food processing. 18/8 stainless steel cannot be hardened by heat treatment and is usually strengthened through cold working.

What Does 18/8 Stainless Steel Mean?

18/8 stainless steel means the alloy contains 18% chromium and 8% nickel. Its composition gives it the name “18/8”.

Is 304 Stainless Steel the Same as 18/8?

Yes, 304 stainless steel is essentially the same as 18/8 stainless steel. However, the designation “304” is a specific alloy designation under the American Iron and Steel Institute (AISI) system, while “18/8” refers more generally to the chromium and nickel content.

Chemical Composition of 18/8 Stainless Steel

Check the table below for the chemical composition of 18/8 stainless steel:

| Iron, Fe | Chromium, Cr | Nickel, Ni | Manganese, Mn | Silicon, Si | Carbon, C | Nitrogen, N | Phosphorus, P | Sulfur, S |

| Balance | 18-20% | 8-10.5% | ≤2.0% | ≤1.0% | ≤0.08% | ≤0.10% | ≤0.045% | ≤0.03% |

Manufacturing and Processing of 18/8 Stainless Steel

18/8 stainless steel is initially produced by melting raw materials—iron, chromium, nickel, and other alloy elements—in an electric arc furnace. This creates molten metal that undergoes refining to remove impurities; substances are added during this process to bind with and separate out these impurities.

After refining, the purified metal is cast into solid shapes like slabs or billets. These castings are then hot rolled, where they are heated and rolled into thinner sheets or other desired forms. Hot rolling adjusts the steel’s thickness and shape. Following this, the steel may be cold rolled at room temperature to achieve a finer thickness and improved surface finish.

The steel then undergoes annealing, a process of heating and slowly cooling to remove internal stresses and enhance its structure. Post-annealing, the steel is pickled in an acid solution to remove any remaining scale or surface impurities.

In the final stages, the steel is cut and shaped into its final form and may receive additional treatments, such as polishing or coating, to further enhance its properties and appearance.

Easy to Weld

18/8 stainless steel is easy to weld due to its balanced composition of chromium and nickel. It does not require pre- or post-weld heat treatments, simplifying the welding process. Common welding methods such as TIG, MIG, and resistance welding work well with 18/8 stainless steel due to its favorable properties.

Compared to other similar stainless steel, like 316 or 430, 18/8 shows superior weldability. For example, while 316 stainless steel, which contains molybdenum, offers enhanced corrosion resistance, it can be more challenging to weld due to the need for precise control over welding parameters. On the other hand, 430 stainless steel, being ferritic, is more susceptible to grain growth and brittleness in the weld area, making it less suitable for welding applications.

Not Hardenable Through Heat Treatment

18/8 cannot be hardened by heat treatment. This is because it is a type of austenitic stainless steel with a specific crystal structure that remains stable even when heated. Instead, hardness is enhanced through other methods like cold working. Cold working involves deforming the steel at room temperature, which strengthens it without changing its basic properties. Its ability to be strengthened through cold working while retaining its core properties makes it one of the most versatile and widely used stainless steels on the market.

Properties of 18/8 Stainless Steel

Here are three major reasons that make 18/8 stainless steel unique:

- High resistance to corrosion due to its high chromium and nickel content.

- Excellent formability, making it easy to shape into various products.

- Non-magnetic due to its austenitic crystal structure.

Physical Properties

Check the table below for the core physical properties of 18/8 stainless steel:

| Property | Typical Value (Metric/Imperial) | Performance |

| Density | 8.00 g/cm³ (0.289 lb/in³) | High density provides good durability and strength. |

| Melting Point | 1400-1455°C (2550 – 2650 °F) | High melting point makes it suitable for high-temperature applications. |

| Thermal Conductivity (100°C) | 16.2 W/m·K (9.36 BTU/hr·ft·°F) | Moderate thermal conductivity is effective for heat dissipation. |

| CTE, Linear (20℃) | 17.3 µm/m-°C (9.61 μin/in·°F) | Low thermal expansion minimizes deformation with temperature changes. |

| Specific Heat Capacity (0-100°C) | 500 J/kg·K (0.12 BTU/lb·°F) | High; suitable for applications involving heat exchange or thermal stability. |

| Electrical Conductivity | 2.5 % IACS | Low electrical conductivity is beneficial for certain electronic applications. |

| Magnetic Properties | Generally non-magnetic | Non-magnetic nature is useful in environments where magnetism can interfere. |

Mechanical Properties

Check the table below for the core mechanical properties of 18/8 stainless steel:

| Mechanical Property | 18/8 (Metric/Imperial) | Performance |

| Tensile Strength | 505 MPa (73.2 ksi) | High strength; similar to construction-grade steels like ASTM A36 used in buildings |

| Yield Strength | 215 MPa (31.2 ksi) | Moderate strength; comparable to mild steel; suitable for many industrial applications |

| Brinell Hardness | 123 HB | Good hardness, similar to aluminum alloys; useful for moderate wear resistance |

| Rockwell Hardness | 70 HRB | |

| Vickers Hardness | 129 HV | |

| Elongation at Break | 70% | Highly ductile; allows significant deformation before breaking; better than many steels |

| Young’s Modulus | 193 GPa (28 msi) | Very stiff; maintains shape under stress; similar to other stainless steels |

Chemical Properties

Check the table below for the core chemical properties of 18/8 stainless steel:

| Chemical Property | Description | Performance |

| Corrosion Resistance | Ability to resist deterioration from chemical reactions | Excellent; superior to many steels but less effective in chloride-rich environments compared to 316 stainless steel |

| pH Sensitivity | Response to different pH levels | Maintains stability across a wide pH range; versatile for various applications |

| Reactivity | Tendency to react chemically | Low; does not react easily with most substances |

| Oxidation Resistance | Resistance to forming oxides | High; forms a protective oxide layer due to high chromium content |

| Passivation | Formation of a protective layer | High; passivates well; enhances corrosion resistance |

| Combustibility | Ability to catch fire | Non-combustible |

| Flammability | Ability to sustain combustion | Non-flammable |

What Are the Advantages and Disadvantages of 18/8 Stainless Steel?

Here are the advantages and benefits of 18/8 stainless steel:

- Excellent corrosion resistance, suitable for various environments.

- High tensile strength, ensuring durability and longevity.

- Non-reactive surface, safe for food and medical applications.

- Easy to clean and maintain, ideal for household and industrial use.

- Attractive appearance, providing a polished and professional look.

The disadvantages and limitations of 18/8 stainless steel are listed below:

- More expensive compared to some other stainless steel grades.

- Stress corrosion cracking can occur in chloride-rich environments.

- Limited high-temperature strength, not ideal for extremely high-temperature applications.

- Needs periodic cleaning to maintain its appearance.

- Heavier weight can be a drawback for certain applications requiring lightweight materials.

Common Applications of 18/8 Stainless Steel

For your convenience, check the table below for a quick understanding:

| Industry | Application | Why 18/8 Suits |

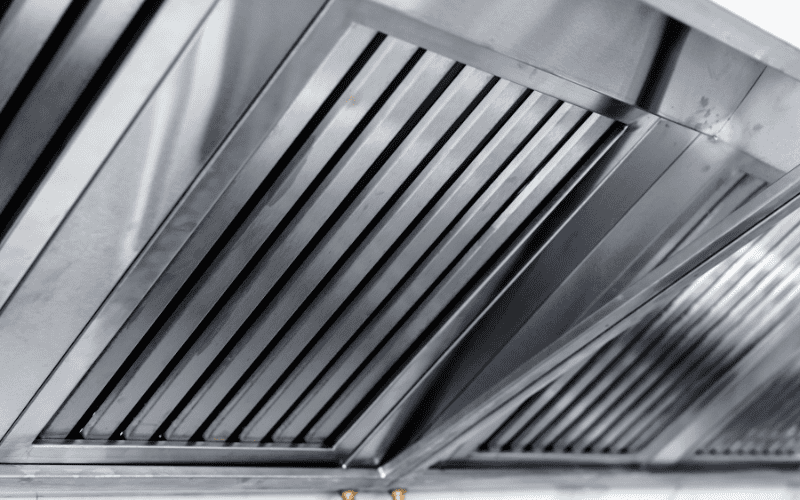

| Food and Beverage | Cutlery, Cookware, Food Processing Equipment, Brewery Tanks | High resistance to corrosion, non-reactive to food, easy to clean |

| Medical Devices | Surgical Instruments, Medical Implants, Hospital Equipment, Sterilization Trays | Biocompatible, resistant to corrosion, easy to sterilize |

| Automotive | Exhaust Systems, Trim and Molding, Engine Components, Fuel Tanks | High strength, excellent corrosion resistance, good thermal properties |

| Architecture and Construction | Building Facades, Railings, Roofing, Cladding | Durability, aesthetic appeal, resistance to weathering and corrosion |

Equivalent Grades of 18/8 Stainless Steel in Different Countries and Regions

18/8 stainless steel is the same as ss 304, and so does its equivalent grades.

| Country/Region | Standard/Specification | Equivalent Grade |

| China | GB/T 3280 | 0Cr18Ni9 |

| USA | ASTM A240 | 304 |

| Germany | DIN EN 10088-2 | 1.4301 (X5CrNi18-10) |

| Russia | GOST 5632 | 08Х18Н10 |

| Europe | EN 10088-2 | X5CrNi18-10 (1.4301) |

| Japan | JIS G4303 | SUS 304 |

| UK | BS 1449 | 304S15, 304S16, 304S31 |

Difference Between 18/8 vs 18/10 vs 18/0 Stainless Steel

Check the table below for a quick comparison between the three:

| Property | 18/8 (304) | 18/0 (430) | 18/10 (316) |

| Type | Austenitic | Ferritic | Austenitic |

| Crystal Structure | FCC (Face-Centered Cubic) | BCC (Body-Centered Cubic) | FCC (Face-Centered Cubic) |

| Chemical Composition | Cr: 18-20%, Ni: 8-10.5% | Cr: 16-18%, Ni: ≤0.5% | Cr: ≤18%, Mo: ≤3%, Ni: ≤14% |

| Corrosion Resistance | Moderate | Low | High |

| Strength | High | Moderate | Higher |

| Hardness | Moderate | High | Moderate |

| Weldability | Good | Poor | Good |

| Magnetic Properties | Non-magnetic | Magnetic | Non-magnetic |

| Cost | Moderate | Low | High |

| Applications | Cookware, general kitchen equipment | Basic kitchen utensils, sinks, appliances | High-end cookware, surgical tools, premium kitchenware |

Need to note that:

- 18/0 is magnetic because it has a ferritic structure, also known as a body-centered cubic crystal structure;

- 18/0 is the cheapest because it does not contain nickel;

- 18/10 is preferred in high-quality kitchenware, cutlery, etc., because higher nickel content provides better corrosion resistance and aesthetic appearance.

- 18/8 is the most commonly used grade of stainless steel because it is suitable for a wide range of applications and offers a balance of performance and cost.

Related Reading

304 vs 316 Stainless Steel (18/8 vs 18/10)

18/0 vs 18/10 Stainless Steel (430 vs 316)

What You Might Also Concern

Now that you have a deeper understanding of 18/8 stainless steel, there are still some common issues that deserve your attention:

Is 18/8 Stainless Steel of Good Quality?

Yes, 18/8 stainless steel is generally considered a high-quality steel. It is strong, durable, long-lasting, and easy to clean and maintain. However, its performance depends on specific applications. For example, it may not be ideal in extreme temperatures or high chloride environments, as it can still corrode over time.

Will 18/8 Stainless Steel Rust?

18/8 stainless steel is resistant to rust because of its chromium content, but it’s not entirely rust-proof. It can still corrode if exposed to strong chlorides (like saltwater or bleach), strong acids (such as hydrochloric or sulfuric acid), or strong alkalis (like sodium hydroxide).

Related Reading

Will Stainless Steel Rust and How Can You Solve It?

Is 18/8 Stainless Steel Magnetic?

Stainless steel 18/8 is usually non-magnetic because it is an austenitic stainless steel. However, when it undergoes cold working or forming, it can develop some magnetic properties. This is because these processes can change part of the austenitic structure into martensite, which is magnetic.

Related Reading

Is Stainless Steel Magnetic?

How Do You Clean 18/8 Stainless Steel?

To clean 18/8 stainless steel, use warm water and mild detergent, then rinse thoroughly and dry with a soft cloth to prevent water spots. For tougher stains or fingerprints, you can use a mixture of vinegar and water or a specialized stainless steel cleaner. Always clean in the direction of the grain to avoid scratching, and avoid using abrasive cleaners or steel wool, which can damage the surface.

Related Reading

How to Clean and Polish Stainless Steel?

Is 18/8 a 300 Series Stainless Steel?

Yes, 18/8 stainless steel belongs to the 300 series of stainless steel. Specifically, it is commonly referred to as 304 stainless steel, which is an austenitic stainless steel known for its corrosion resistance and versatility. Common grades in this series include 304, 316, 301, and 302.

Is 18/8 Stainless Steel Non-Toxic?

Yes, 18/8 stainless steel is non-toxic. It is commonly used in food and beverage applications, kitchen utensils, and medical instruments because it is non-reactive and safe for contact with food and human tissues.

Summary & Furthermore

This article briefly explains the definition, composition, properties, advantages and disadvantages, applications, and other important aspects of 18/8 stainless steel. To learn more about stainless steel or other steel types, check out our blog or contact our metal experts.

As a leading manufacturer and solutions provider of specialty steel, SteelPRO delivers multi-industry application solutions and customized services. We guarantee 100% product quality and are committed to growing together with our customers. Visit our website to learn more, or send us an inquiry. We will contact you shortly!

Contact Us

Any questions or demands please feel free to leave messages for us here. We will give our expert response as soon as possible.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons